Efficient steam heat supply and waste heat recovering system

A waste heat recovery system and steam heating technology, applied in the direction of steam central heating system, heating system, household heating, etc., can solve the problems of large amount of boiler sewage, large emission loss, affecting the environment of the factory area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

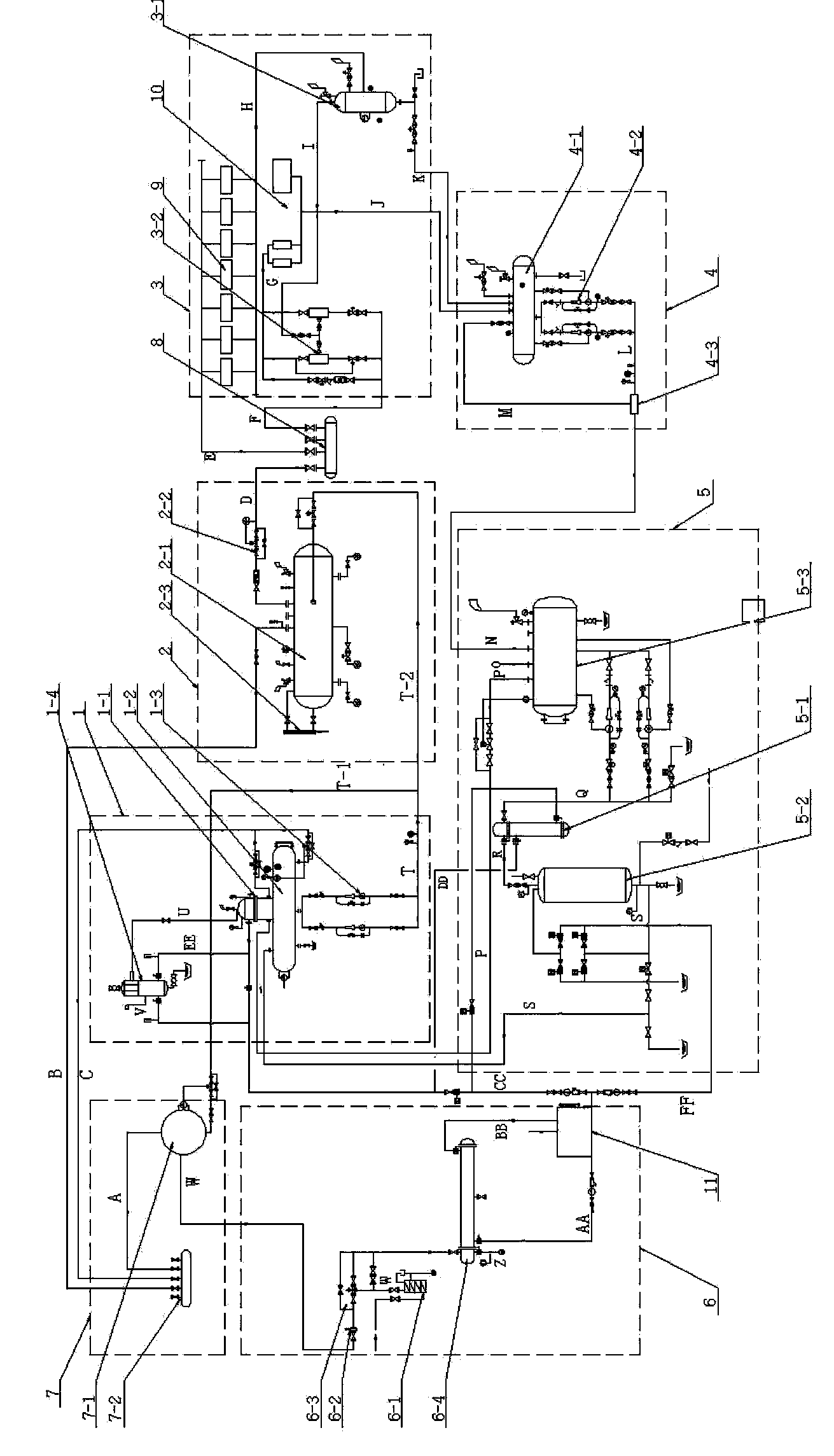

[0023] Embodiments, with reference to the accompanying drawings, a high-efficiency steam heating and waste heat recovery system, including a heat accumulator 2, a boiler automatic blowdown system 6 and a boiler steam distribution system 7, is characterized in that a low-level thermal oxygen removal system 1 is set in the system , Steam cascade utilization system 3 and condensate iron removal system 5.

[0024] The low-level thermal deaeration system 1 is composed of a high-efficiency deaeration device 1-1, a deaeration water tank 1-2, an anti-cavitation water pump 1-3, and a waste heat recovery device 1-4 for deaeration and exhaust gas; the high-efficiency deaeration device 1-1 communicates with the deaeration water tank 1-2 with the C pipeline and the boiler sub-cylinder 7-2, connects with the deoxygenation and exhausted steam waste heat recovery device 1-4 with the U pipeline, and uses the EE pipeline to communicate with the deoxygenated and exhausted steam waste heat recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com