Anti-eccentric wear protection device for sucker rod rotation

A protection device and anti-eccentric wear technology, applied in drill pipe, drill pipe, casing and other directions, can solve the problems of high maintenance cost of the sucker rod protection device, increasing the difficulty of equipment management, and easy wear of the overrunning clutch. Long service life, less frequent maintenance, and longer stroke effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

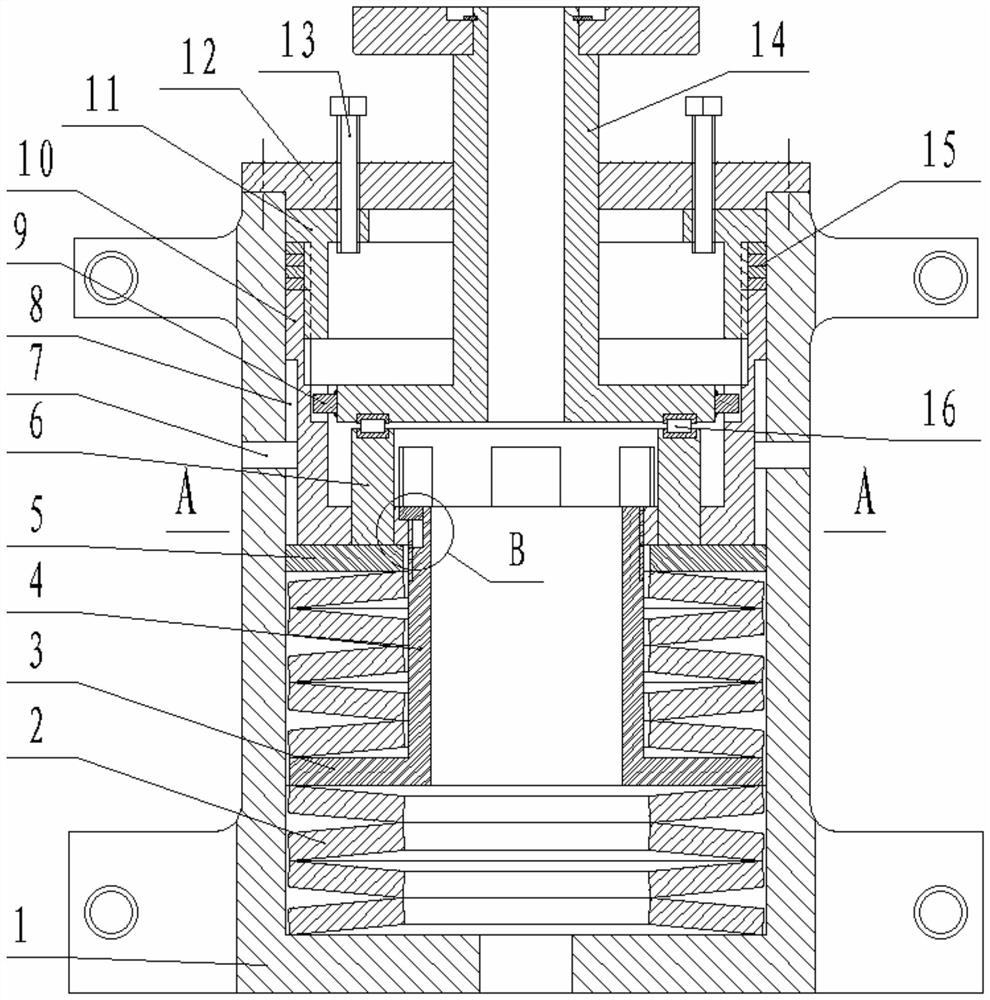

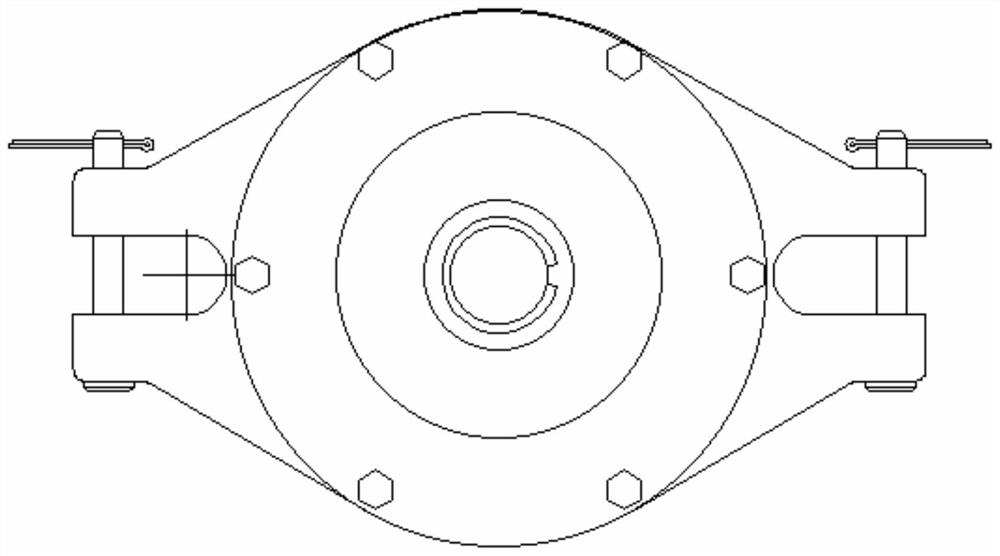

[0041] Such as figure 1 As shown, this embodiment includes a housing 1, a disc spring group and an automatic rotation mechanism. The upper end of the housing 1 is provided with an end cover 12, and the end cover 12 is connected to the housing 1 by bolts. The disc spring group is installed At the bottom inside the housing 1 , the automatic rotation mechanism is arranged between the disc spring set and the end cover 12 . The above are common structures in the prior art, and will not be repeated here.

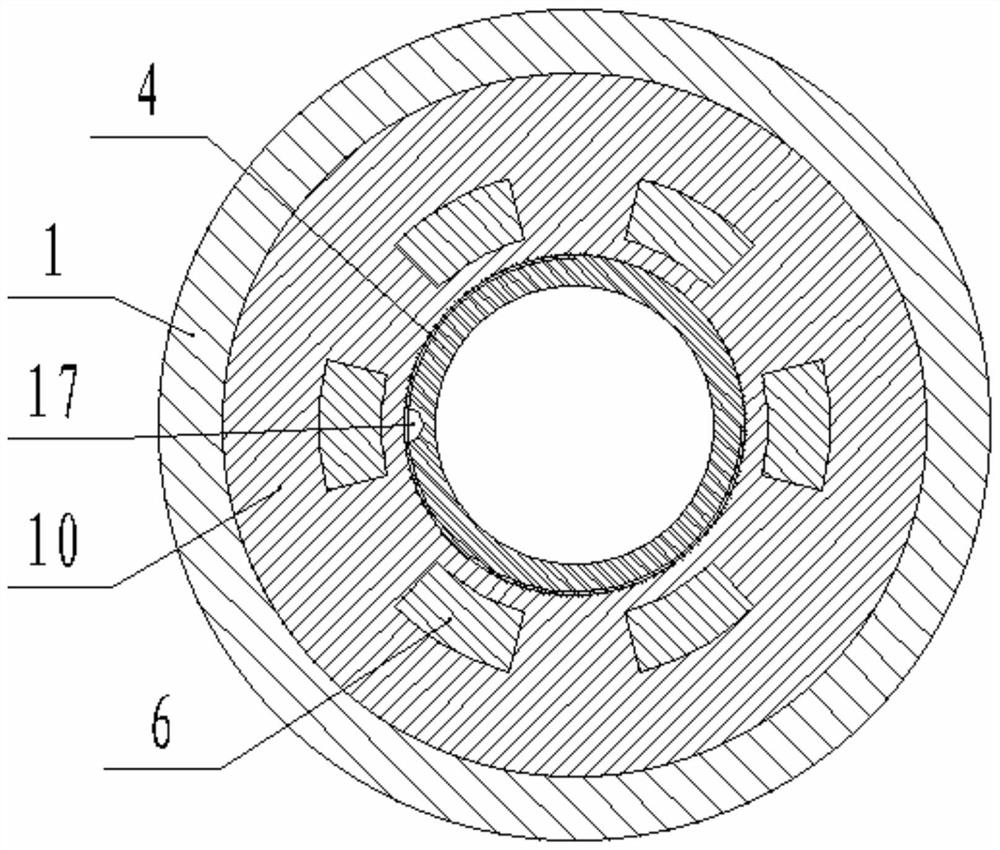

[0042] Such as figure 1 As shown, the automatic rotation mechanism includes a guide sleeve and a rotation sleeve 14. A bar-shaped groove 8 is provided on the outside of the guide sleeve. The length direction of the bar-shaped groove 8 is consistent with the axial direction of the housing 1. The strip groove 8 is correspondingly provided with an anti-rotation bolt 7, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com