Transmission mechanism for tripe-perched vehicle

A technology of transmission mechanism and amphibious vehicle, which is applied in the field of modern transportation to achieve the effects of high adaptability to harsh environments, strong working reliability and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

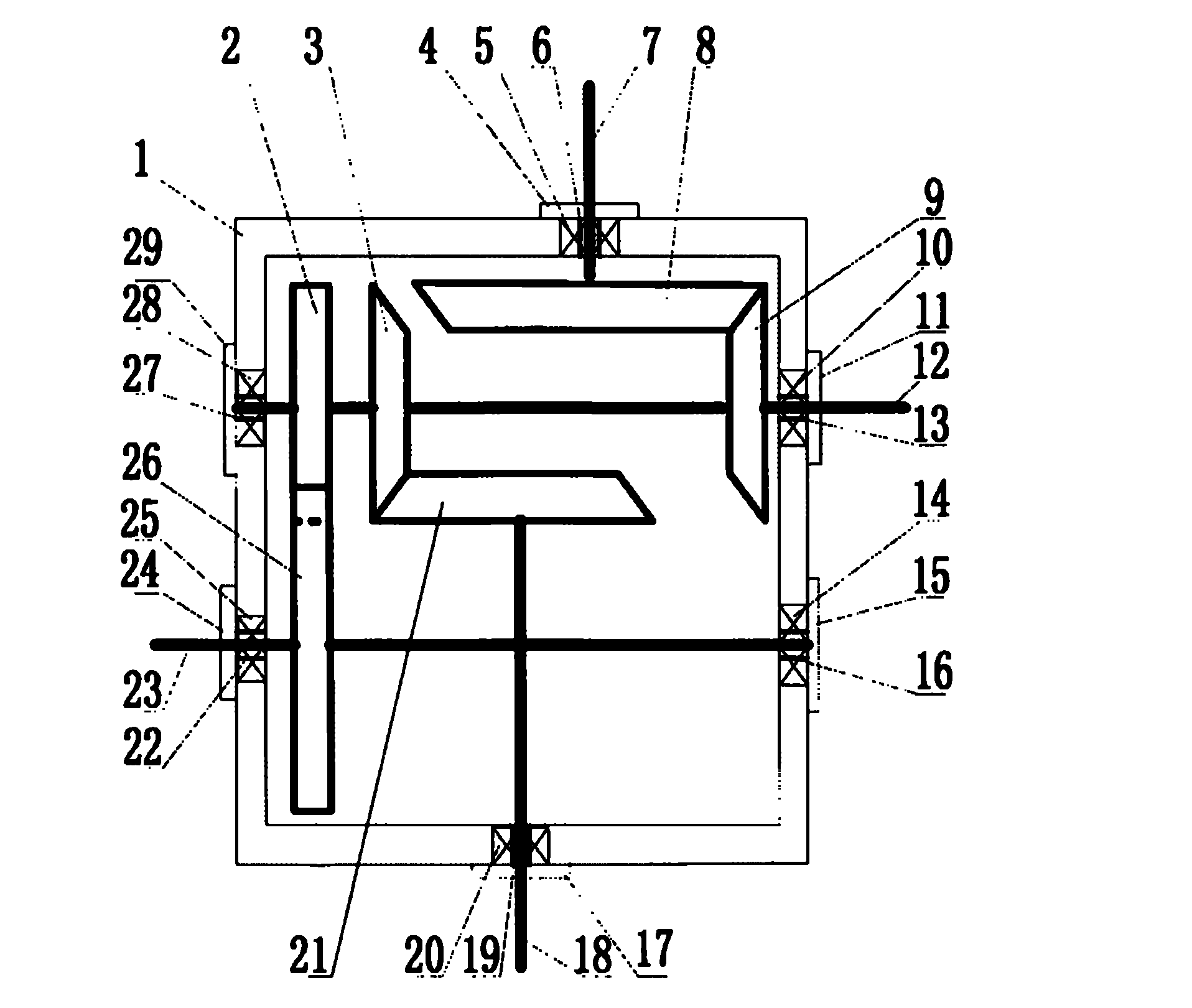

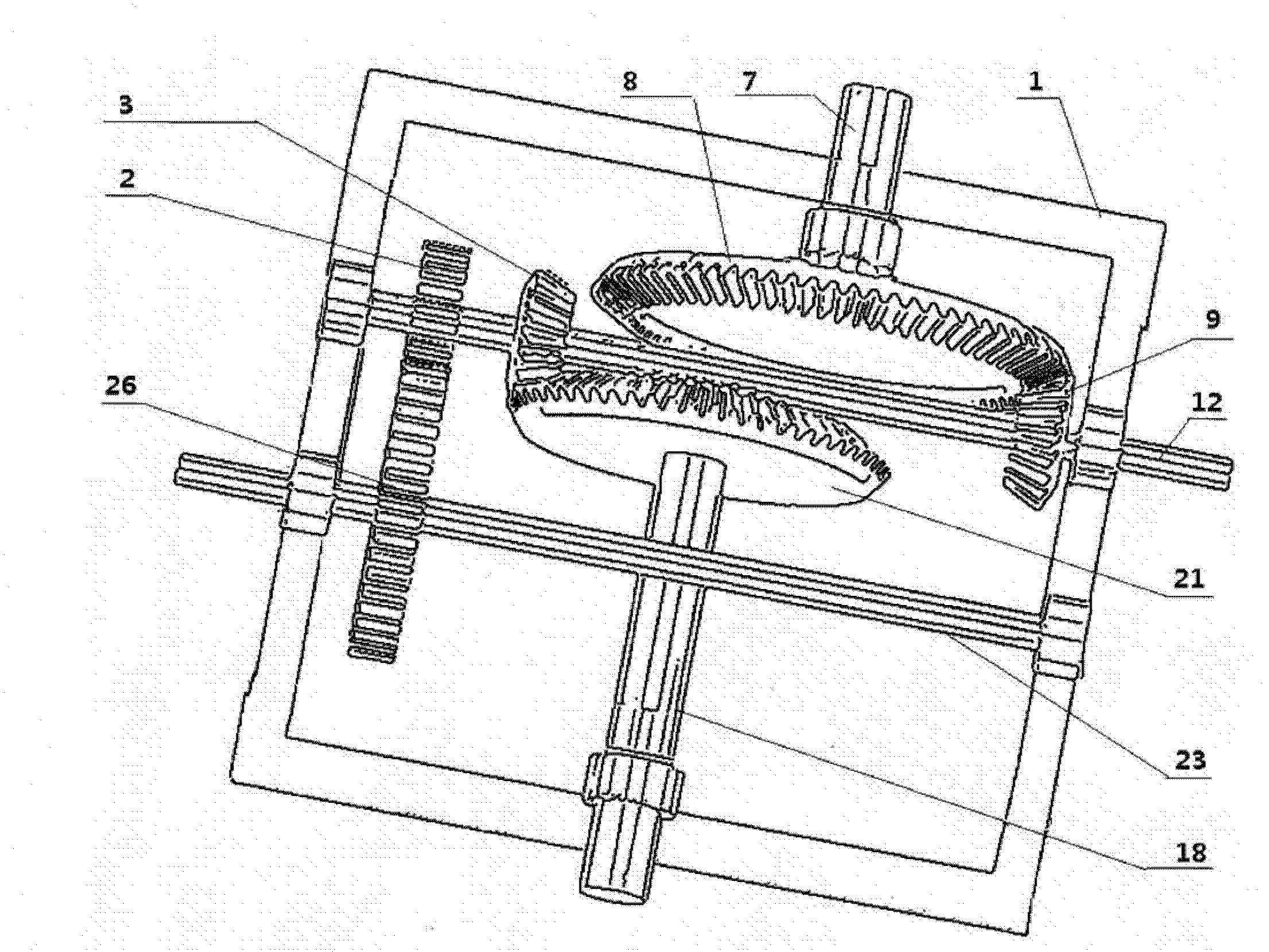

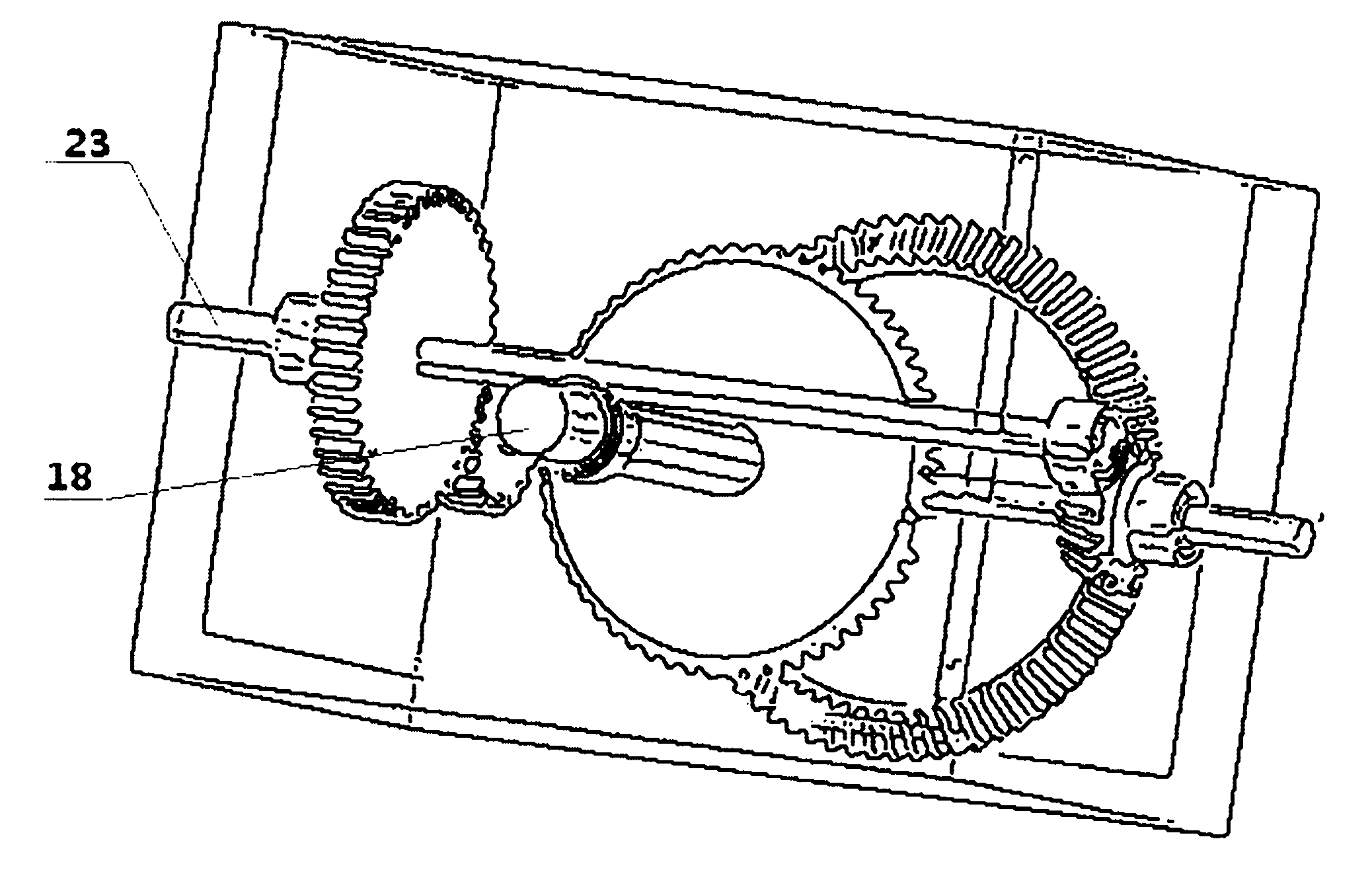

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. Such as Figure 1-3 As shown, a transmission mechanism of an amphibious vehicle includes a box body 1, an input shaft 12, an output shaft A7, an output shaft B18, an output shaft C23, a straight bevel gear DA9, a straight bevel gear EA3, a spur gear FA2, Straight bevel gear DB8, straight bevel gear EB21 and spur gear FB26; said straight bevel gear DA9 and straight bevel gear DB8 constitute a straight bevel gear pair D, straight bevel gear EA3 and straight bevel gear EB21 constitutes a pair of straight bevel gears E; the pair of straight bevel gears D and E are approximately symmetrically distributed in space; the pair of spur gears FA2 and spur gear FB26 constitute a pair of spur gears gear pair F;

[0020] The input shaft 12 is equipped with a straight bevel gear DA9, a straight bevel gear EA3 and a spur gear FA2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com