Reel storage method and storage cabinet of reel

A storage cabinet and reel technology, applied in packaging and other directions, can solve the problems of falling deformation, large unit storage space, and the reel cannot be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific technical solution for applying the present invention will be further described below in conjunction with the accompanying drawings.

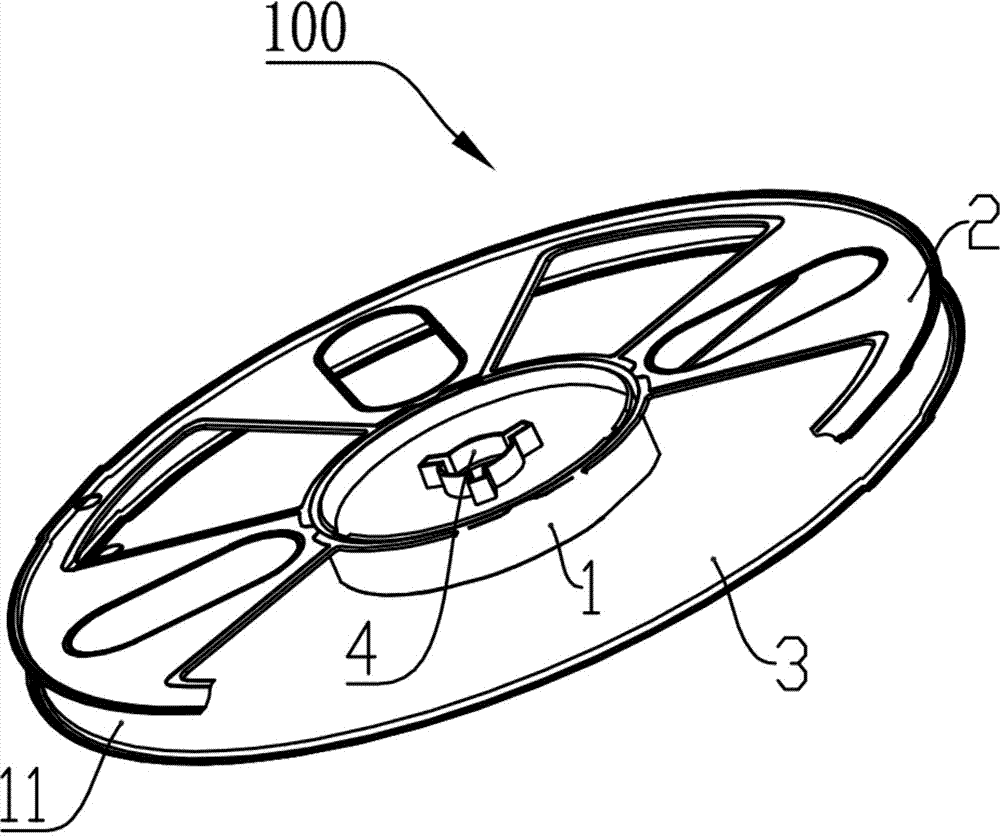

[0031] Such as figure 1 As shown, the reel 100 includes a winding part 1 arranged along the axial direction, and a first wafer part 2 and a second wafer part 3 arranged in parallel at both ends of the winding part 1 along the radial direction. The radial diameter D of a disc part 2 and the second disc part 3 is the same, there is an axial space 11 between the first disc part 2 and the second disc part 3 and the axial space of the axial space The distance is at least twice the thickness of the wafer part (2 or 3), so that at least two wafer parts (2 or 3) can be accommodated.

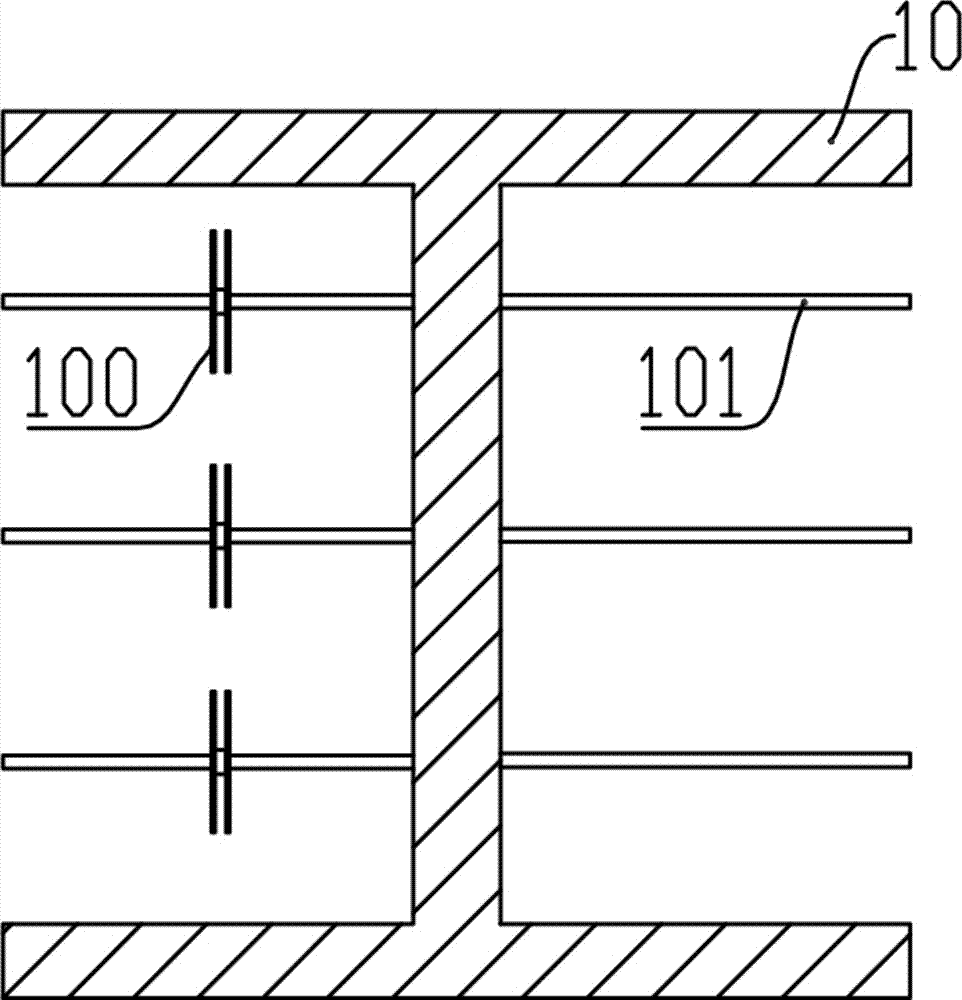

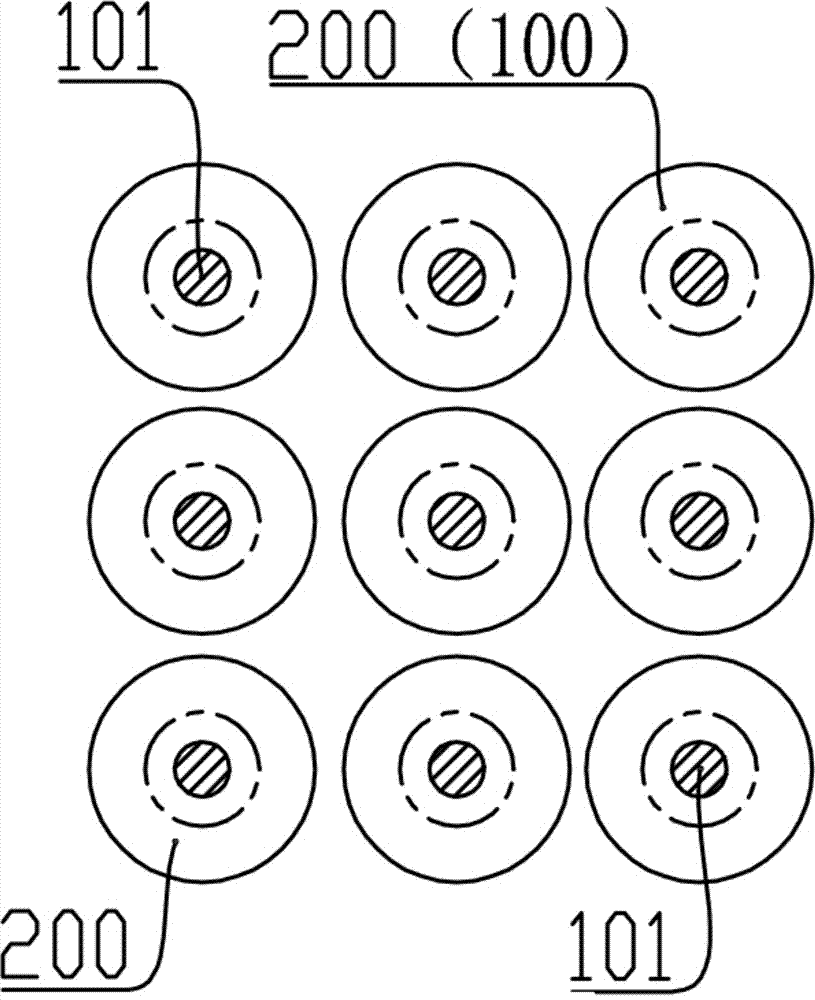

[0032] Such as Figure 4 , Figure 5 and Figure 6 As shown, a reel storage method, when the reel 100 is stored, a plurality of the reels 100 are stacked in the axial direction to form a reel row 200, and the front and rear adjacent front reel row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com