Non-sprayed-concrete anchor net supporting method of underground construction broken surrounding rocks

A technology for crushing surrounding rock and supporting with anchor nets, which is applied in underground chambers, bolt installation, earth drilling, etc., can solve the problems of increased support costs, complicated processes, and increased actual consumption, and achieve rapid and timely support. , The effect of improving the working environment and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

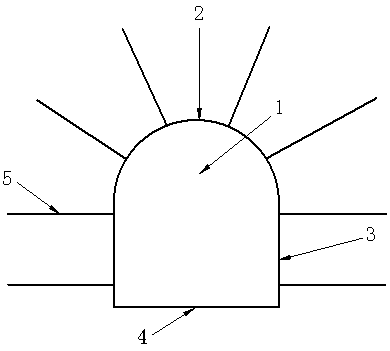

[0016] A. Roadway or tunnel excavation: According to the designed roadway or tunnel excavation, cycle drilling, charging, blasting, ventilation, prying, and partial de-ballasting to form a roadway or tunnel 1, remove the top arch 2 and two gangs 3, and the bottom plate 4 pumice stone, so that there is no pumice stone on the rock surface, and ensure the safety of construction workers;

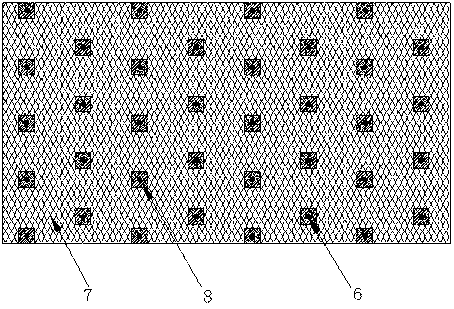

[0017] B. Drill the bolt hole: drill the bolt hole 5 using a drill bit with a diameter of 38mm, and the depth of the bolt hole is 1800mm. In order to ensure that the pipe ring of the pipe-slotted bolt 6 can fasten the anchor plate 8, the bolt hole is drilled. The depth of 5 can be slightly deeper than 1800mm. When drilling the bolt hole 5, several rows of holes are drilled perpendicular to the roadway or the surrounding rock wall of the tunnel, such as figure 1 As shown, each row of holes includes 8 bolt holes 5, of which 3 to 5 are arranged in the vault 2, and 2 are arranged in the two sides 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com