Multifunctional rock tunnel boring machine support system and method

A tunnel boring machine, multi-functional technology, applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the problems of harsh tunnel operating environment, high labor intensity, casualties, etc., to improve the tunnel operating environment, and the use method is simple and effective , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

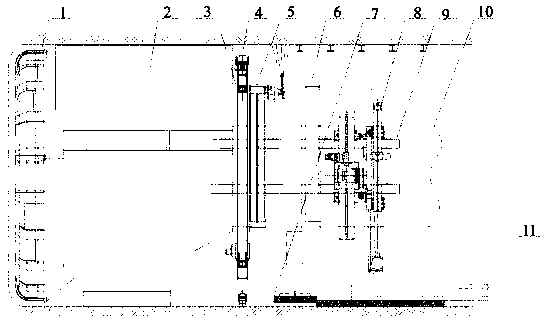

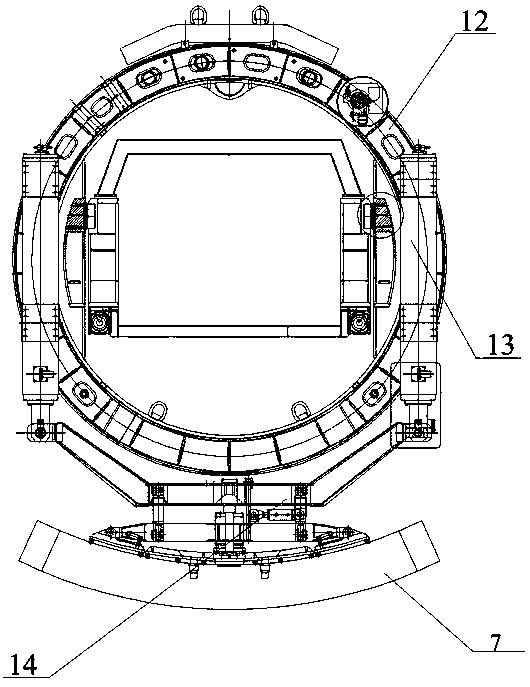

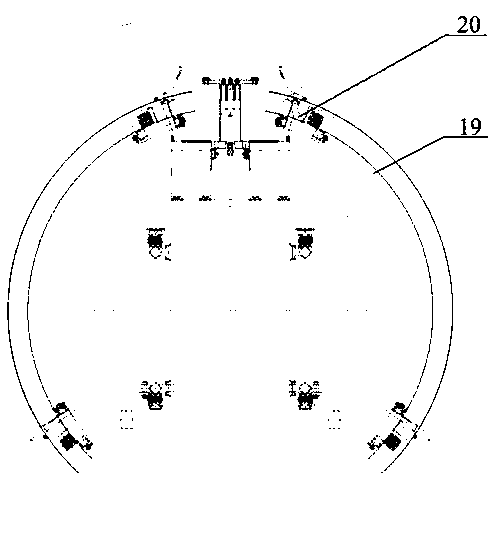

[0035] Such as Figure 1-7 As shown, a multi-functional rock tunnel boring machine support system includes a shield 2, a steel arch installer 3, a front spray mixer 5, a segment installer 6 and a bolter 8; the shield 2. It is set between the front part of the main beam 10 of the roadheader and the cutter head 1. The steel arch installer 3, the front mixer 5, the segment installer 6 and the bolter 8 can be slidably arranged in sequence. On the main beam 10 on the rear side of the shield 2, the steel arch installer 3 and the front spray mixer 5 are arranged adjacently.

[0036] Two sets of sliding rails 9 are respectively symmetrically arranged on both sides of the main beam 10; the steel arch installer 3 and the front spray mixer 5 share a set of sliding rails 9, and the segment installer 6 and The bolter rig 8 shares a set of slide rails 9; the steel arch installer 3, the pre-type spray mixer 5, the annular mobile frame 16 and the bolt drill 8 are all equipped with a sliding ...

Embodiment 2

[0042] A method for supporting a multifunctional rock tunnel boring machine, aimed at surrounding rocks with better integrity, comprising the following steps:

[0043] (1) After the surrounding rock is excavated by the cutter head 1 of the roadheader, it is temporarily supported by the shield 2; when the surrounding rock leaks out of the shield 2, the steel arch installer 3 assembles the annular arch 4 at a certain distance;

[0044] (2) Bolting rig 8 sets bolts along the radial direction of the tunnel, so that the annular arch frame is fixed with the surrounding rock through the bolts;

[0045] (3) Lap the steel bar row and steel mesh between two adjacent ring-shaped arch frames, and then use the pre-type spray mixer 5 to spray concrete to seal the surrounding rock of the tunnel in time to complete the supporting of the surrounding rock.

Embodiment 3

[0047] A method for supporting a multifunctional rock tunnel boring machine, aimed at surrounding rocks with poor integrity, comprising the following steps:

[0048] (1) After the surrounding rock is excavated by the cutter head 1 of the roadheader, it is temporarily supported by the shield 2; when the surrounding rock leaks out of the shield 2, the segment installer 6 assembles the continuous closed segments;

[0049] (2) After the segment is closed, the pre-type spray mixer 5 is connected to the grouting hole of the segment through the pipeline, and the gap between the segment and the surrounding rock is filled in time to complete the supporting of the surrounding rock.

[0050] The multi-functional rock tunnel boring machine support system and support method of the present invention integrates multiple support methods, can realize the joint use of multiple support methods, enhances the adaptability of the roadheader to different strata, and can realize The timely sealing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com