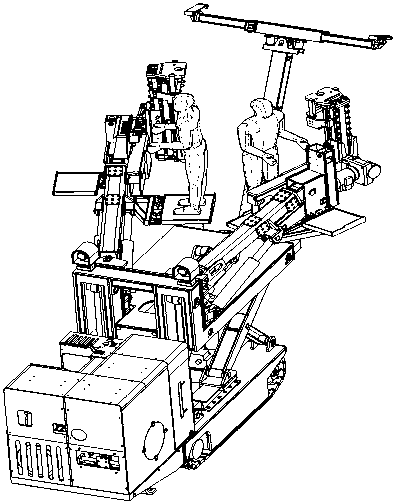

Electro-hydraulic anchor protection control double basket type two arm anchor cable anchor rod drill truck

A technology for bolting rigs and anchoring protection, which is applied to the installation of bolts, automatic control systems for drilling, drilling equipment, etc. Comfort and safety, high drilling efficiency and success rate, the effect of reducing redundant connecting rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

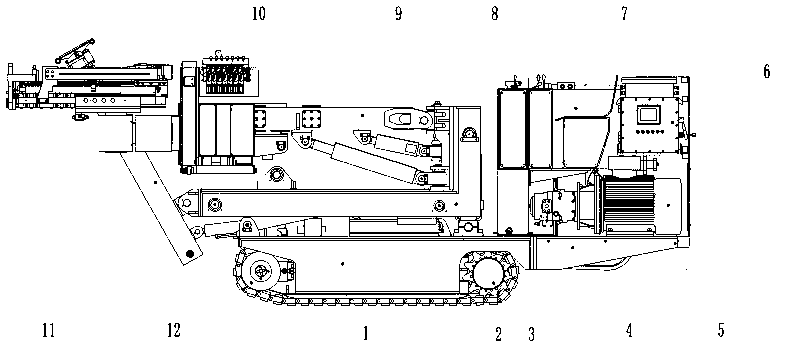

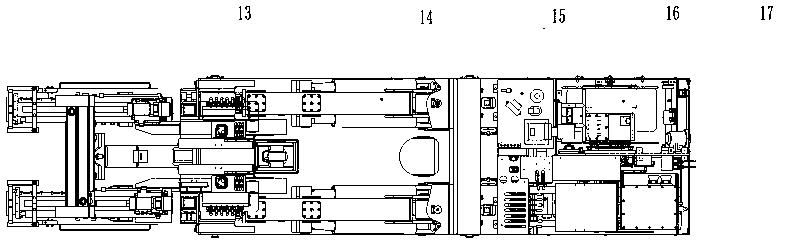

[0040] The present invention will be further described below in conjunction with accompanying drawing:

[0041] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, which is only intended to describe specific embodiments of the present invention in detail, without any limitation to the present invention, and the scope of protection of the present invention shall be determined by the claims.

[0042] Its main technical parameters are as follows:

[0043] Adapt to roadway economic width (mm): 3000-6000

[0044] Adapt to roadway economic height (mm): 2600-4500

[0045] Side bolt support height range (mm): 600-4500

[0046] The maximum height of the anchor cable of the top anchor (mm): 6000

[0047] Dimensions (mm): 6100×1400×2300

[0048] Ground clearance (mm): 260

[0049] Machine weight (t): about 17

[0050] Installed power (kW): 55

[0051] Voltage level (V): 1140

[0052] Number of drill a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com