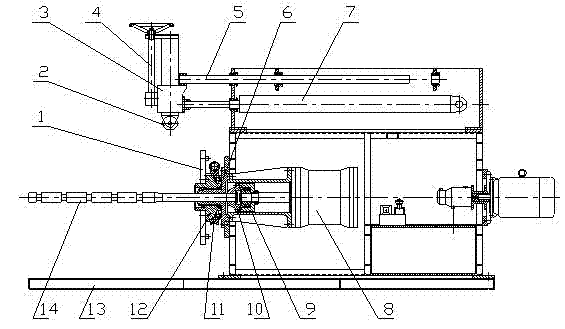

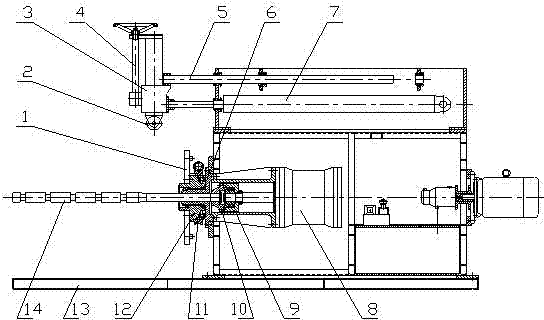

Horizontal cramp machine for laminating motor stator iron cores

A motor stator and horizontal technology, which is applied in the field of special mechanical equipment for lamination of motor stator iron core, can solve the problem of small diameter range of motor stator iron core, poor lamination uniformity of vertical lamination machine, stator core rotation Difficulties and other problems, to achieve the effect of reduced investment, neat lamination, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] like figure 1 As shown, the main hydraulic cylinder 8 is horizontally fixed on the machine body through the supporting fixed sleeve 6, the auxiliary hydraulic cylinder 7 is horizontally fixed above the main hydraulic cylinder 8, and the piston rod of the main hydraulic cylinder 8 is connected with a piston rod tension transmission mechanism, and the tension The transmission mechanism is that two plane thrust bearings are installed on the piston rod of the main hydraulic cylinder 8, and the right tension sleeve 9 is installed on the bearing, and the right tension sleeve 9 is connected with the left tension sleeve 10 on the tension rod 14 through bolts, and at the same time, When the tension rod 14 rotates with the stator core of the motor, the piston rod of the main hydraulic cylinder 8 cannot rotate. There are at least five annular grooves on the tension rod 14; Connection; the supporting fixed sleeve 6 is connected with the supporting movable sleeve 12, and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com