Vehicle-mounted guard bar drilling machine with foldable drilling frame

A drilling machine and drilling stand technology, applied in drilling equipment and methods, directional drilling, earth-moving drilling, etc., can solve problems such as the influence of the driver's driving field of vision, the drilling depth of the drill pipe is not deep enough, etc., so as to increase the aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

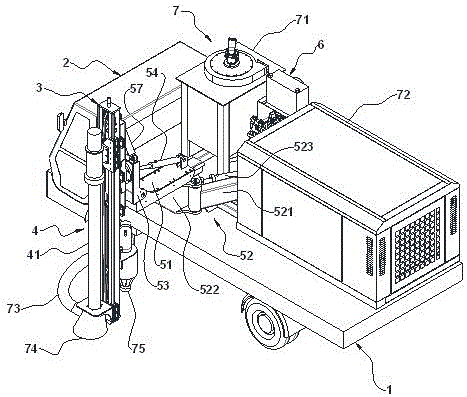

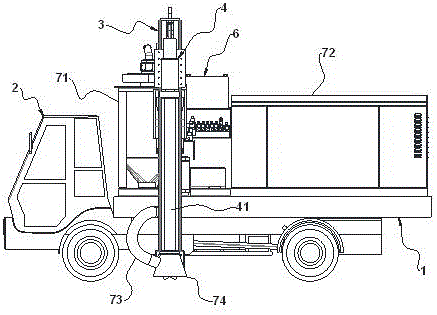

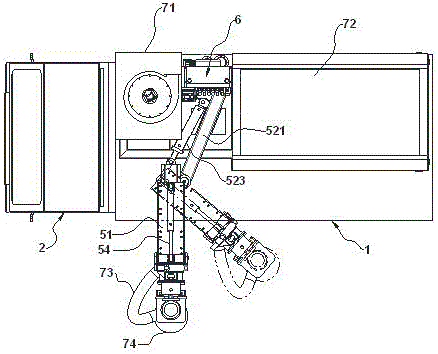

[0027] like Figure 1-6 As shown, the vehicle-mounted guardrail drilling machine that can fold the drill frame includes a body 1, a drill frame 3 and a drill pipe assembly 4. The lower end of the body 1 is provided with a traveling mechanism, and the front end of the body 1 is provided with a cab 2. A hydraulic control mechanism, the hydraulic control mechanism is mainly a multi-way control valve. The drill rod assembly 4 is installed on the drill frame 3 in a liftable manner, and also includes a retracting mechanism arranged on the vehicle body 1 for retracting the drill frame 3 located outside the vehicle body 1 to the top of the vehicle body 1 5.

[0028] The folding mechanism 5 includes a base 51, a rotating mechanism 52 arranged on the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com