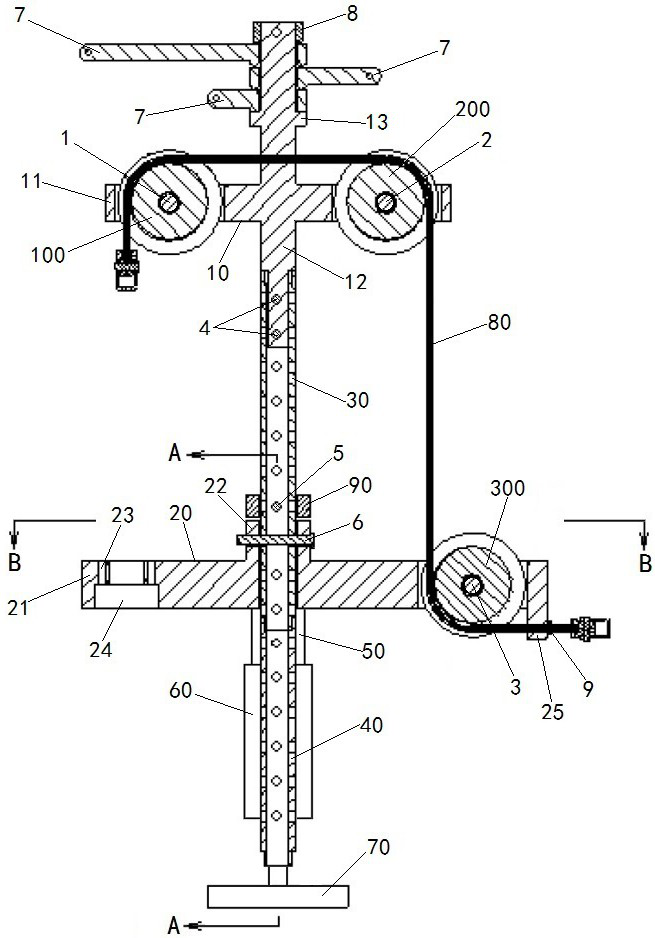

Wellhead hoisting device

A hoisting device and winding technology, which is applied in the direction of hoisting device, portable lifting device, drilling equipment, etc., can solve the problems of small limited range, limited vertical height adjustment, and high cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

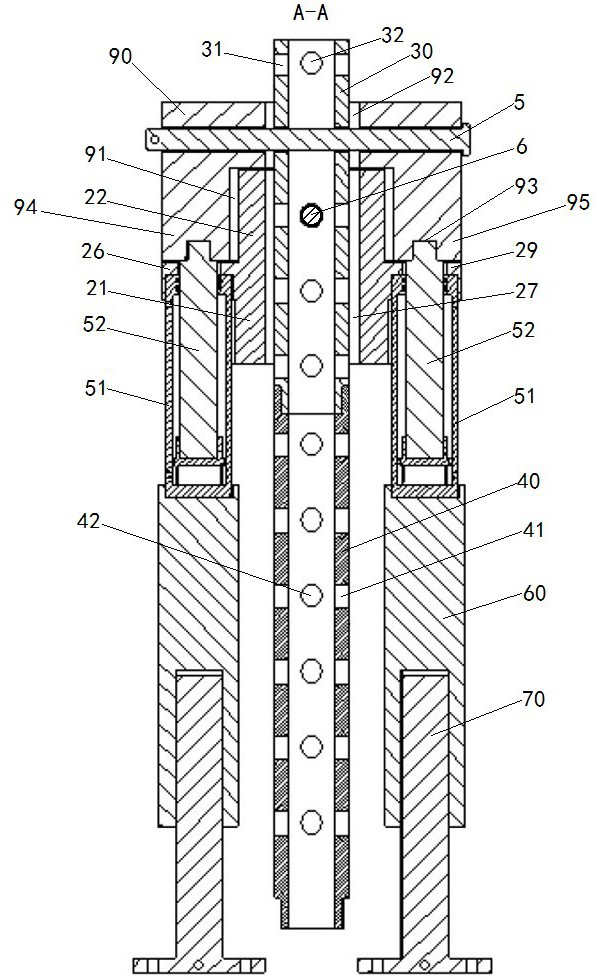

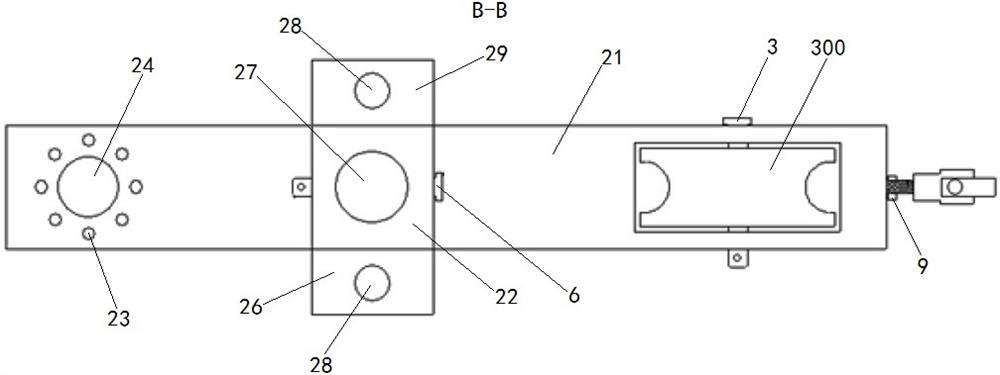

Method used

Image

Examples

Embodiment 2

[0075] Embodiment 2 of the wellhead hoisting device in the present invention: the difference from the above-mentioned embodiment is that the blowout prevention pipe string may not be connected on the ground and directly connected to the traction rope as a whole, but may be connected to a When installing a blowout preventer, connect a section of the blowout preventer with the traction rope, and then continue to connect the blowout preventer with the continuous rise of the pulley frame, so that the blowout preventer string is continuously added to the blowout preventer connection during the rising process made.

Embodiment 3

[0076] Embodiment 3 of the wellhead hoisting device in the present invention: the difference from the above-mentioned embodiments is that the equipment to be hoisted can be other equipment that needs to be installed at the wellhead except the blowout pipe.

[0077] Embodiment 4 of the wellhead hoisting device in the present invention: the difference from the above embodiment is that the stabilizing rod fixed on the top of the pulley frame can be welded or screwed on the top of the pulley frame.

Embodiment 5

[0078] Embodiment 5 of the wellhead hoisting device in the present invention: the difference from the above embodiments lies in that the number of stabilizing rods can be only two or more.

[0079] Embodiment 6 of the wellhead hoisting device in the present invention: the difference from the above embodiments lies in that the connecting column of the pulley frame is screwed to the top of the uppermost bearing rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com