Aircraft air spring lifter

A technology of air springs and supports, which is applied in the field of aircraft air spring lifting supports, can solve the problems of inapplicability of large-tonnage aircraft, inability to lift at three points synchronously, poor safety, etc., and achieve improved support efficiency, large application value, and The effect of increasing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

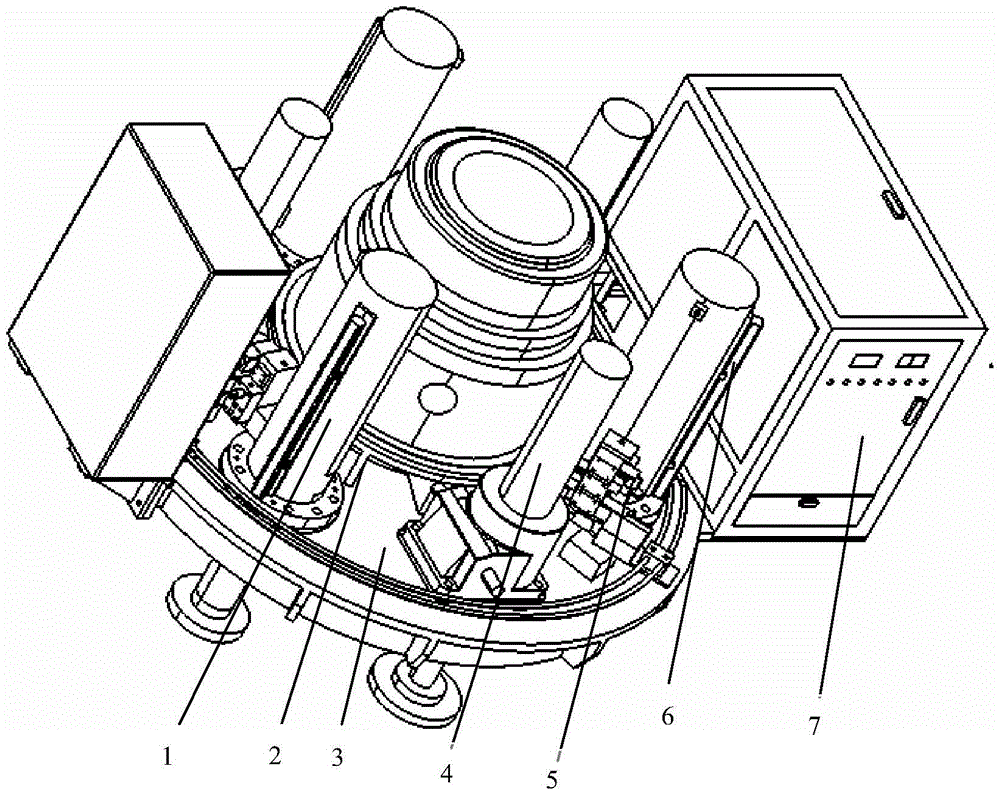

[0013] The aircraft air spring lifting support of the invention includes a hydraulic station, a hydraulic lifting cylinder, a base, an auxiliary support, an air spring installation base plate, a control valve group, and a displacement sensor.

[0014] The air spring installation base plate is a circular flange structure, which is set on the base for installing the air spring. Three hydraulic sound drop cylinders and three auxiliary supports are arranged around the air spring at intervals and evenly distributed on the air spring installation base plate In addition, the hydraulic lifting actuators are all provided with control valve groups and connected to the hydraulic station, and the displacement sensors are arranged on the side walls of the hydraulic lifting actuators.

[0015] The lower end of the base is provided with reinforcing ribs, the purpose of whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com