Movable lifting device

A lifting device and lifting frame technology, applied in the lifting device, lifting frame and other directions, can solve the problems of inconvenient operation and slow speed, and achieve the effects of high reliability, large lifting weight and fast movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

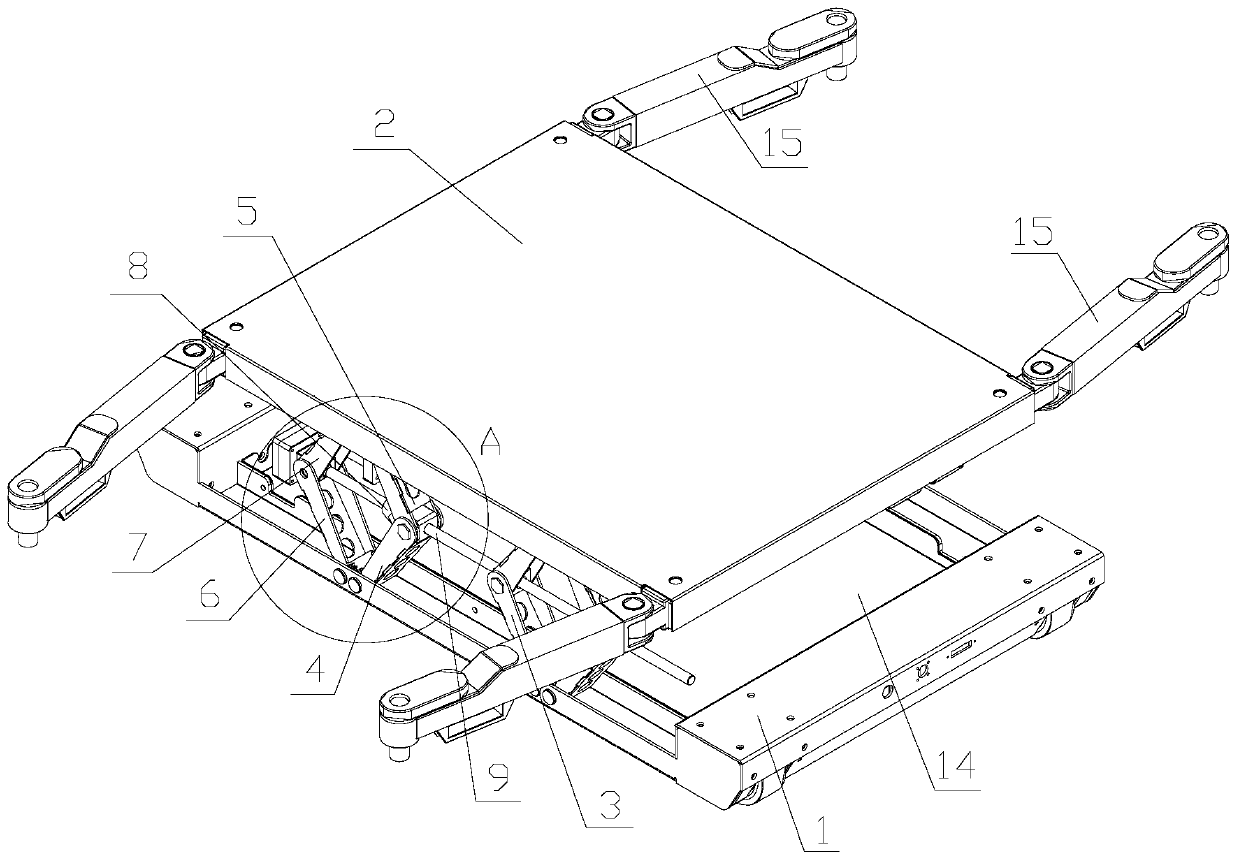

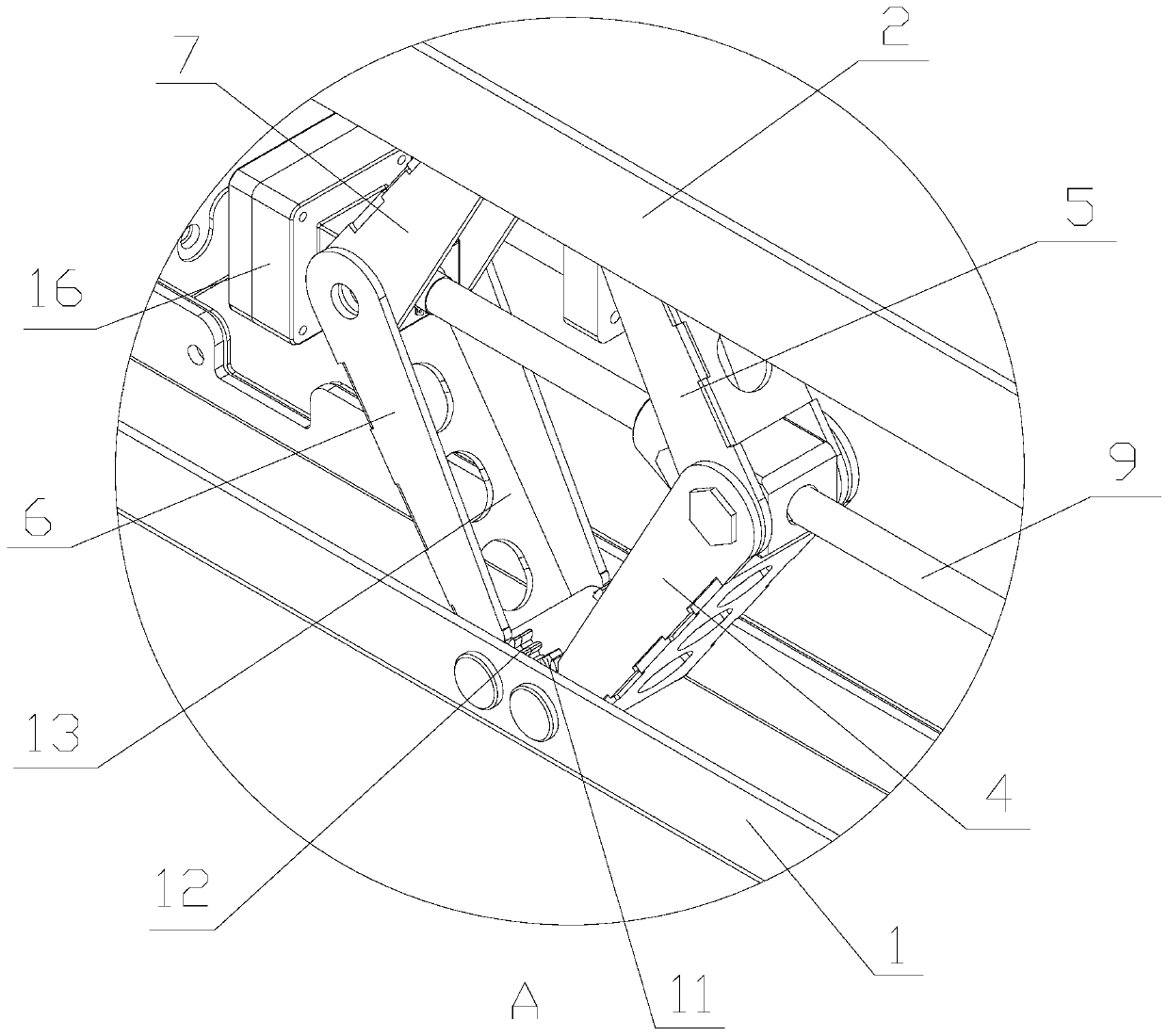

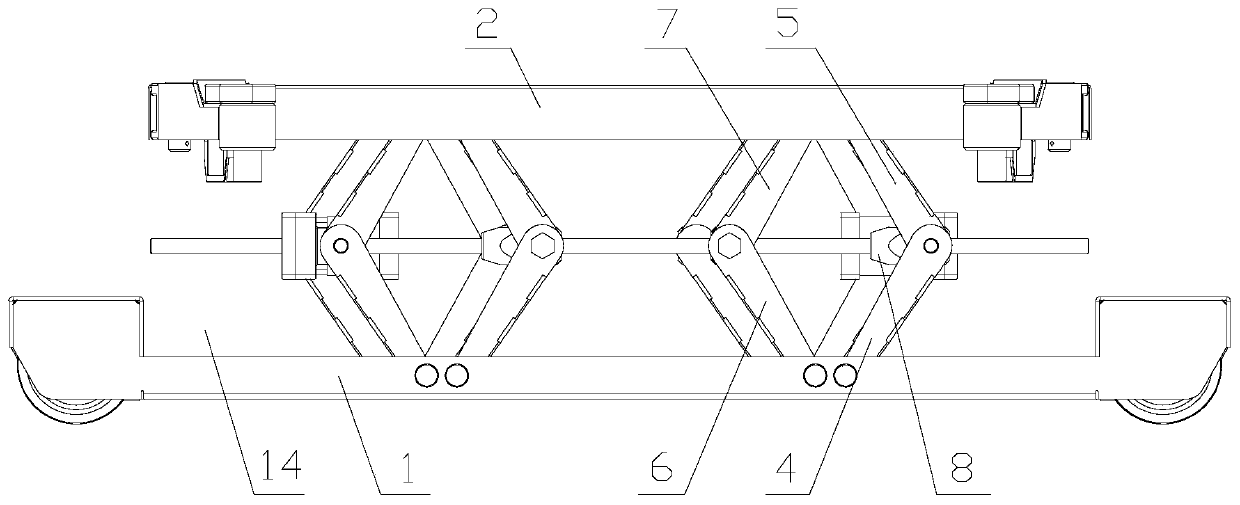

[0024] Such as figure 1 As shown, a mobile lifting device includes a freely walking chassis 1 and a pallet 2 arranged above the chassis 1. A lifting mechanism 3 is arranged between the chassis 1 and the pallet 2 to control the pallet 2 to rise or fall. The lifting mechanism 3 is provided with two groups, which are respectively located on both sides of the top surface of the chassis 1 .

[0025] Specifically, such as Figure 1~5 As shown, the lifting mechanism 3 includes a lifting frame, a leading screw 9 and a drive motor 10, and the lifting frame includes a first lower bracket 4 and a first upper bracket 5; one end of the first lower bracket 4 rotates with the chassis 1 Connected, the other end of the first lower bracket 4 is movably connected with a lead screw nut 8, and one end of the first upper bracket 5 is rotationally connected with the first lower bracket 4, and the other end of the first upper bracket 5 is rotationally connected with the tray 2, so The above-mention...

Embodiment 2

[0029] Such as figure 1 As shown, a mobile lifting device includes a freely walking chassis 1 and a pallet 2 arranged above the chassis 1. A lifting mechanism 3 is arranged between the chassis 1 and the pallet 2 to control the pallet 2 to rise or fall. The lifting mechanism 3 is provided with two groups, which are respectively located on both sides of the top surface of the chassis 1 .

[0030] Specifically, such as Figure 1~5 As shown, the lifting mechanism 3 includes a lifting frame, a leading screw 9 and a drive motor 10, and the lifting frame includes a first lower bracket 4 and a first upper bracket 5; one end of the first lower bracket 4 rotates with the chassis 1 Connected, the other end of the first lower bracket 4 is movably connected with a lead screw nut 8, and one end of the first upper bracket 5 is rotationally connected with the first lower bracket 4, and the other end of the first upper bracket 5 is rotationally connected with the tray 2, so The above-mention...

Embodiment 3

[0035] Such as figure 1 As shown, a mobile lifting device includes a freely walking chassis 1 and a pallet 2 arranged above the chassis 1. A lifting mechanism 3 is arranged between the chassis 1 and the pallet 2 to control the pallet 2 to rise or fall. The lifting mechanism 3 is provided with two groups, which are respectively located on both sides of the top surface of the chassis 1 .

[0036] Specifically, such as Figure 1~5As shown, the lifting mechanism 3 includes a lifting frame, a leading screw 9 and a drive motor 10, and the lifting frame includes a first lower bracket 4 and a first upper bracket 5; one end of the first lower bracket 4 rotates with the chassis 1 Connected, the other end of the first lower bracket 4 is movably connected with a lead screw nut 8, and one end of the first upper bracket 5 is rotationally connected with the first lower bracket 4, and the other end of the first upper bracket 5 is rotationally connected with the tray 2, so The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com