Panty-hose machine

A pantyhose machine and integrated technology, applied in the field of weft knitting small circular knitting machine, can solve the problems of uneven force, complicated process change, low rotation speed of the knitting mechanism, etc., to achieve stable machine operation and accuracy, and easy operation of process change. , the effect of compact structure combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

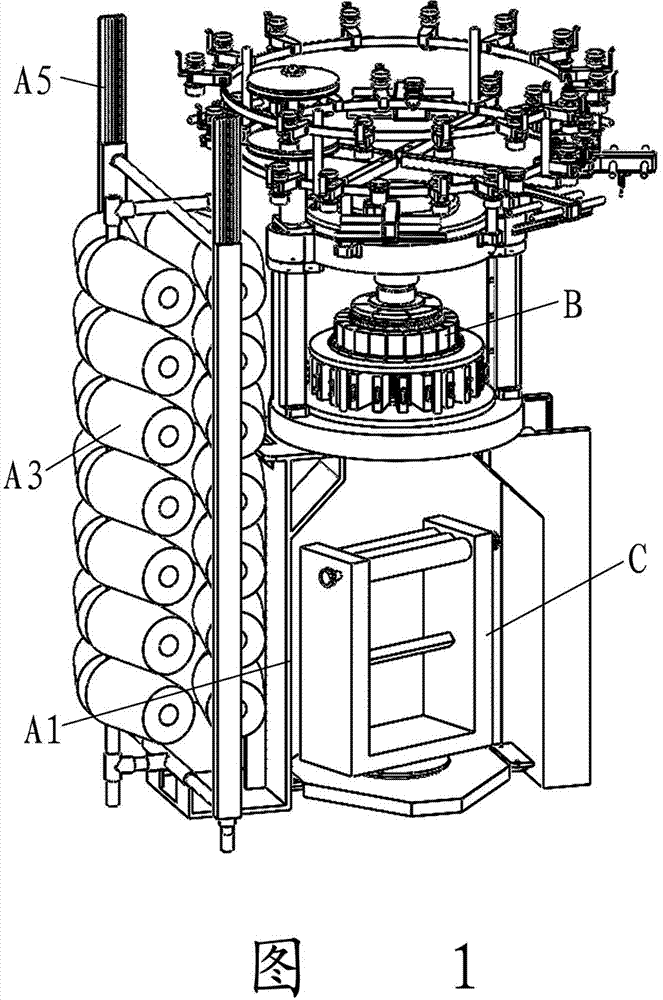

[0055] like figure 1 As shown, the integrated pantyhose machine is composed of three parts: a yarn feeding mechanism, a knitting mechanism B, and a cloth rolling mechanism C. It is characterized in that,

[0056] The yarn feeding mechanism is fixed by the machine foot A1, and the bottom between several machine feet A1 is provided with a tripod. There are multiple frame rods A8 standing between the upper and lower parts of the frame, the weaving mechanism B is installed and fixed on the frame, the weaving mechanism B is arranged above the cloth rolling mechanism C, and the top of the upper part of the frame passes through A plurality of vertical rods A9 supports the top creel A6 in the yarn feeding mechanism;

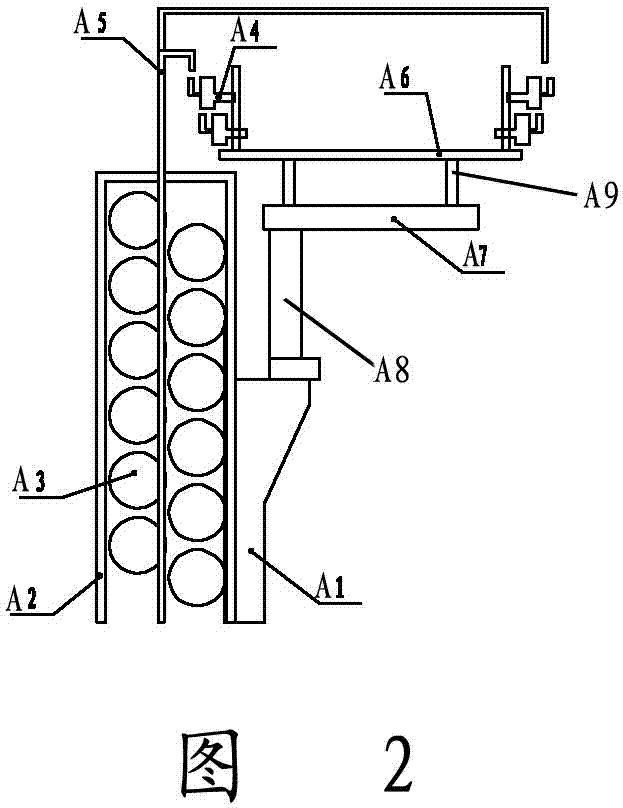

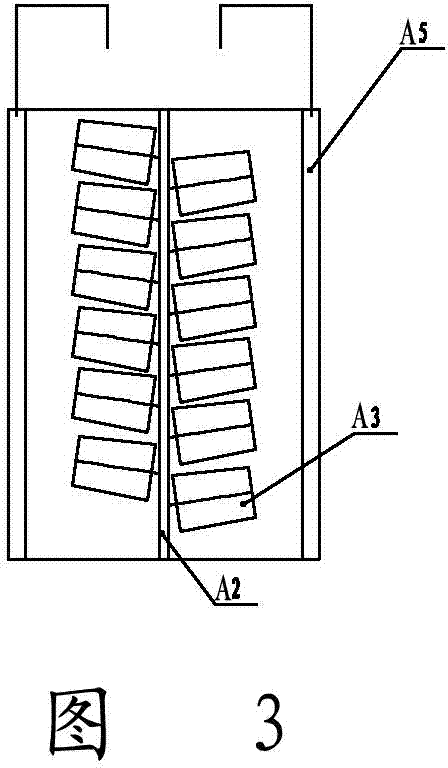

[0057] like figure 2 , image 3 As shown, among them, the yarn feeding mechanism includes the machine foot A1, the air duct type integrated yarn creel A2, the yarn bobbin A3, the yarn feeder A4, the air duct A5, the machine top yarn creel A6, and the frame A7. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com