Water soluble polymer mixed emulsion, coating and preparation method thereof

A water-soluble polymer, mixed milk technology, applied in chemical instruments and methods, coatings, synthetic resin layered products, etc., can solve the problem of increasing the production process and complexity of the process, the production labor intensity of operators, and the safety of coating films. It can reduce the complexity of the production process, save energy and raw materials, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

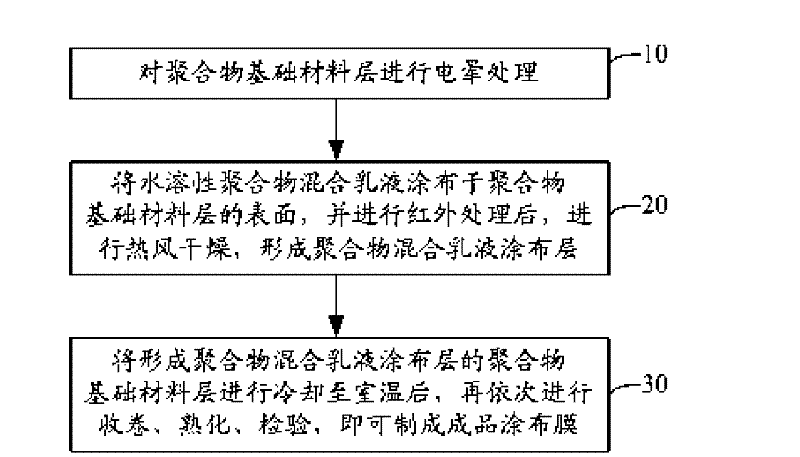

[0029] figure 1 It is a schematic flow chart of the coating film preparation method of the present invention. like figure 1 Shown, described preparation method comprises the following steps:

[0030] Step 10: Corona treatment of the polymer base material layer to achieve a surface wetting tension of the polymer base material of 38 dyn / cm 2 above.

[0031]In order to achieve good adhesion of general polymer materials, according to the material and application, the value of corona treatment should make the surface wetting tension of the polymer base material reach 38dyn / cm 2 ~58dyn / cm 2 . Corona treatment is an electric shock treatment that makes the surface of the substrate more adherent. The principle is to use high-frequency and high-voltage corona discharge on the surface of the treated plastic (high-frequency AC voltage up to 500V / m 2 ~15000V / m 2 ), and low-temperature plasma is generated, which causes free radical reactions on the surface of the plastic to cross-li...

Embodiment 1

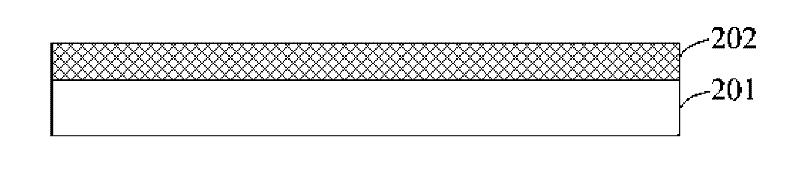

[0042] Stir and mix polyvinylidene chloride emulsion, water-based polyurethane adhesive, silane and triethanolamine at a mass ratio of 100:10:2:1, wherein the stirring speed is 50 revolutions per minute, thereby forming a water-soluble polymer mixed emulsion, The water-soluble polymer mixed emulsion is coated on the surface of the biaxially stretched polypropylene film, and the surface wetting tension of the biaxially stretched polypropylene film reaches 38 dyn / cm after corona treatment 2 Above, after infrared treatment and hot air drying in sequence, after cooling to room temperature, a polymer mixed emulsion crystal coating layer is formed on the surface of the biaxially stretched polypropylene film, and then winding, aging, cutting, and inspection are performed in sequence. Finished coating film is made.

Embodiment 2

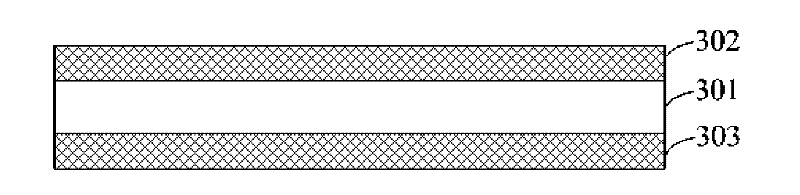

[0044] Stir and mix the acrylic emulsion, alcohol-soluble polyurethane adhesive, phosphoric acid ester and high-carbon aliphatic alcohol at a mass ratio of 100:15:3:1.5, wherein the stirring speed is 100 rpm to form a water-soluble polymer Mixed emulsion, the water-soluble polymer mixed emulsion is coated on the surface of the polyvinyl chloride calendered film, and the surface wetting tension of the polyvinyl chloride calendered film reaches 48 dyn / cm after corona treatment 2 , followed by infrared treatment and hot air drying, and after cooling to room temperature, a polymer mixed emulsion crystal coating layer is formed on the surface of the biaxially stretched polypropylene film, and then winding, aging, cutting, and inspection are carried out in sequence, and the product can be produced. into a finished coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com