Construction method for overall formwork one-time forming structure of pier

A construction method and technology for forming structures, which are applied to bridges, bridge parts, bridge construction, etc., can solve the problems of difficult to guarantee construction quality, poor vibrating, and difficulty in secondary formwork and stubble, so as to avoid non-compact concrete. , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

[0024] In this embodiment, the technical requirements for steel bar binding and welding, large-scale steel formwork splicing construction technology, post-tensioning prestressed tensioning technology of tie beams, etc. will not be described in detail, and the implementation mode of the one-time forming structure installation of the integral formwork of the bridge pier involved in the present invention will be elaborated. .

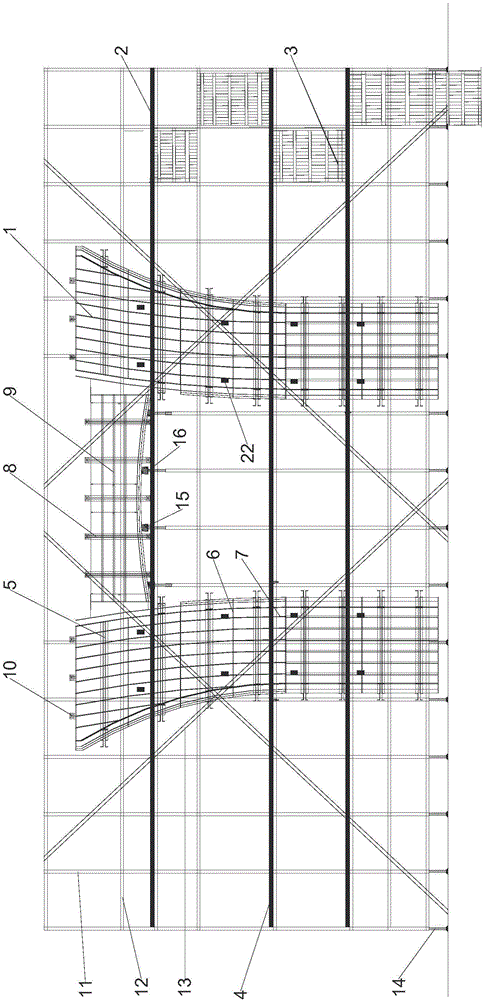

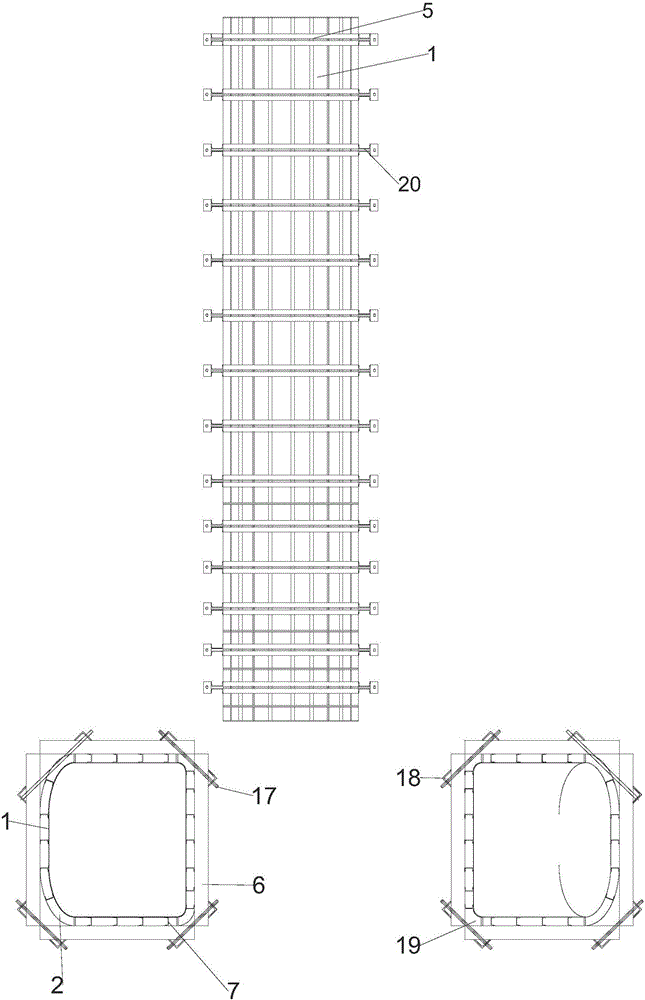

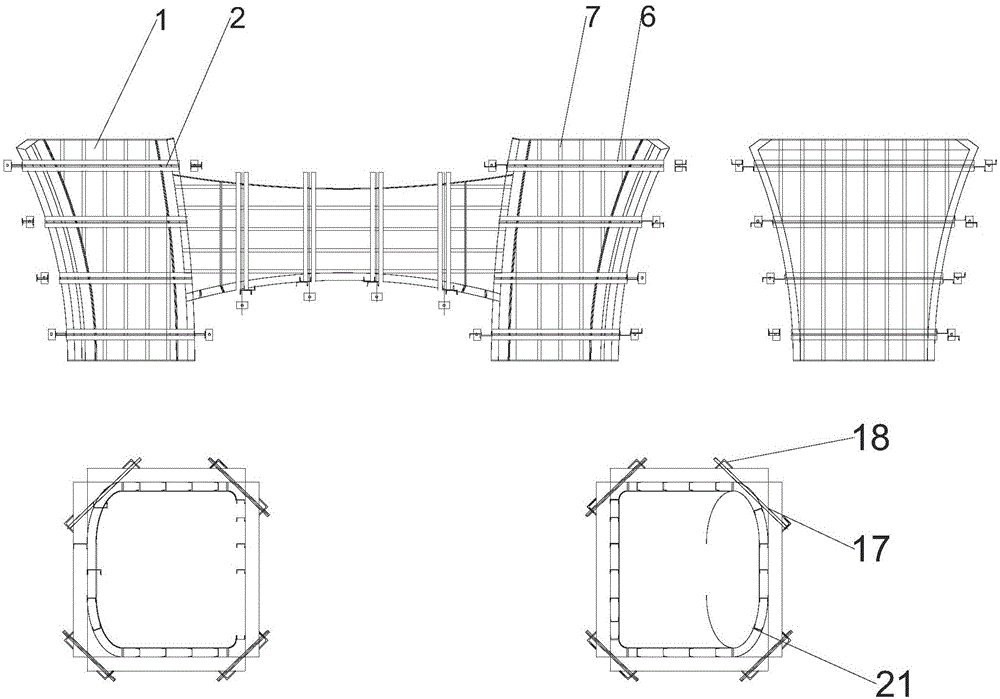

[0025] figure 1 It is a schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com