Incineration process for processing ammine containing exhaust gas and system thereof

A waste gas and process technology, which is applied in the field of incineration process and system for treating ammonia-containing waste gas, can solve the problems of high emission rate and high emission concentration, and achieve the effects of reducing heat load, saving fuel and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

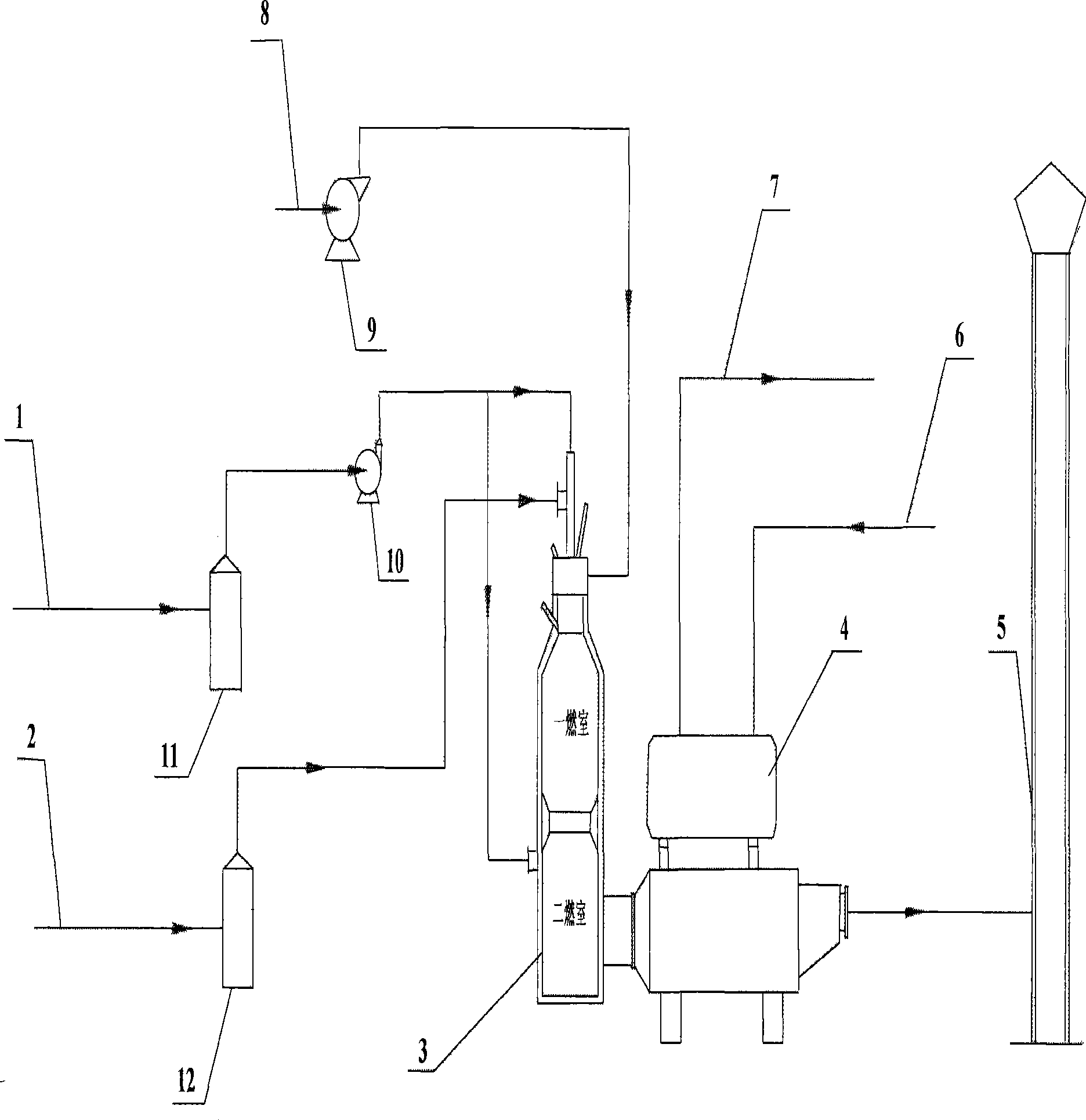

[0015] The incineration process and system for treating ammonia-containing waste gas according to the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The incineration process for treating ammonia-containing waste gas according to the present invention divides the ammonia-containing waste gas into two paths and simultaneously enters two combustion chambers of an incinerator; the volume ratio of the ammonia-containing waste gas entering the two combustion chambers can be adjusted, and enters a The volume percentage of ammonia-containing waste gas in the combustion chamber is 40%-70%, and the volume percentage of ammonia-containing waste gas entering the second combustion chamber is 30%-60%.

[0017] In a combustion chamber, in the presence of oxygen, the ammonia-containing waste gas undergoes pyrolysis and oxidation of ammonia. The reaction equation is as follows:

[0018] 2NH 3 →N2+3H 2

[0019] N 2 +O 2 →2NO

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com