Device and method for measuring fluorescent oil flow friction force field

A measuring device and friction force technology, applied in the field of wind tunnel test model surface relative friction force field measuring device, can solve the problems that model development cannot provide effective support, friction resistance cannot be provided, cumbersome and complicated calibration process, etc., to reduce the impact , Reduce measurement costs, reduce links and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

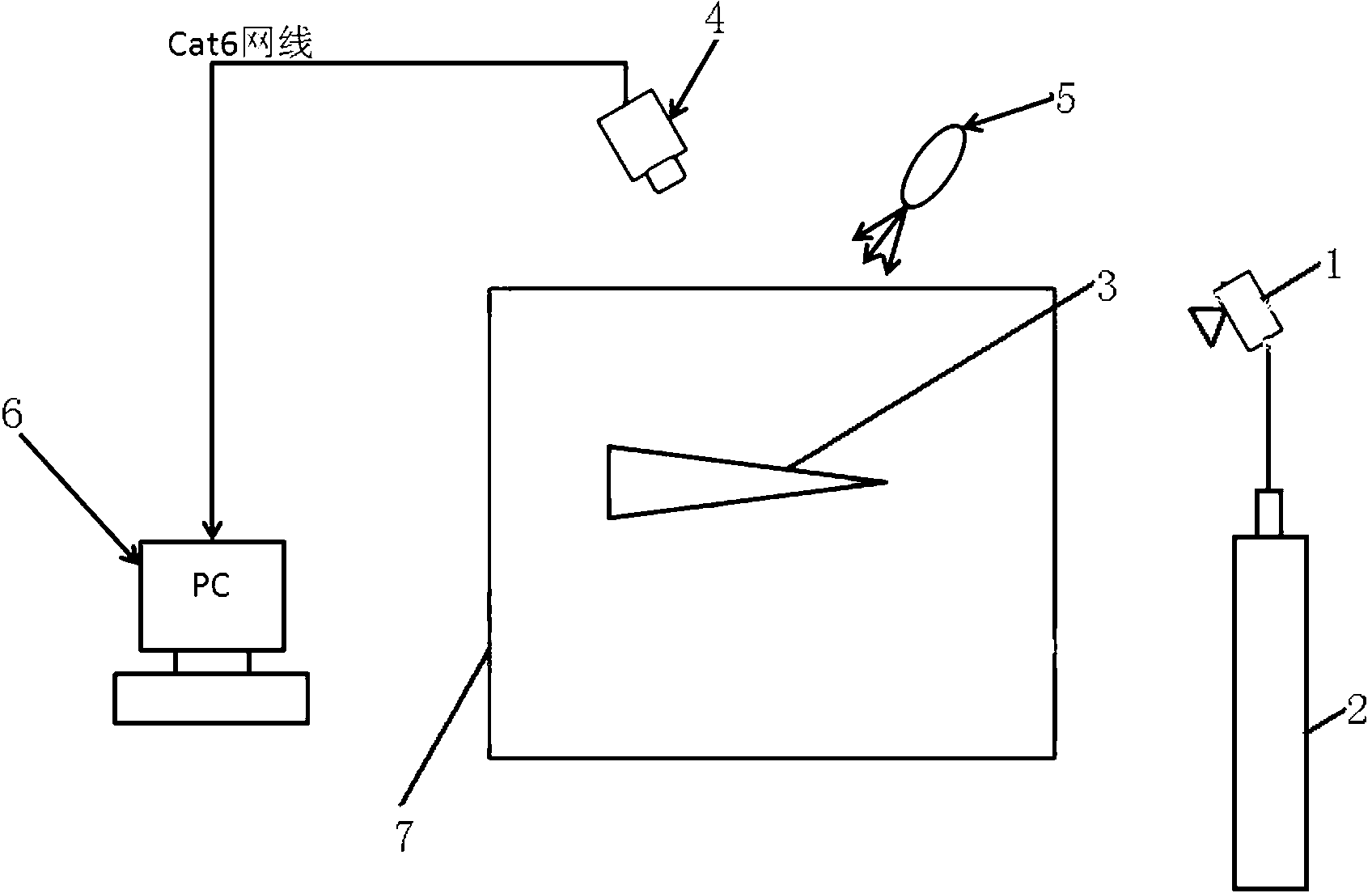

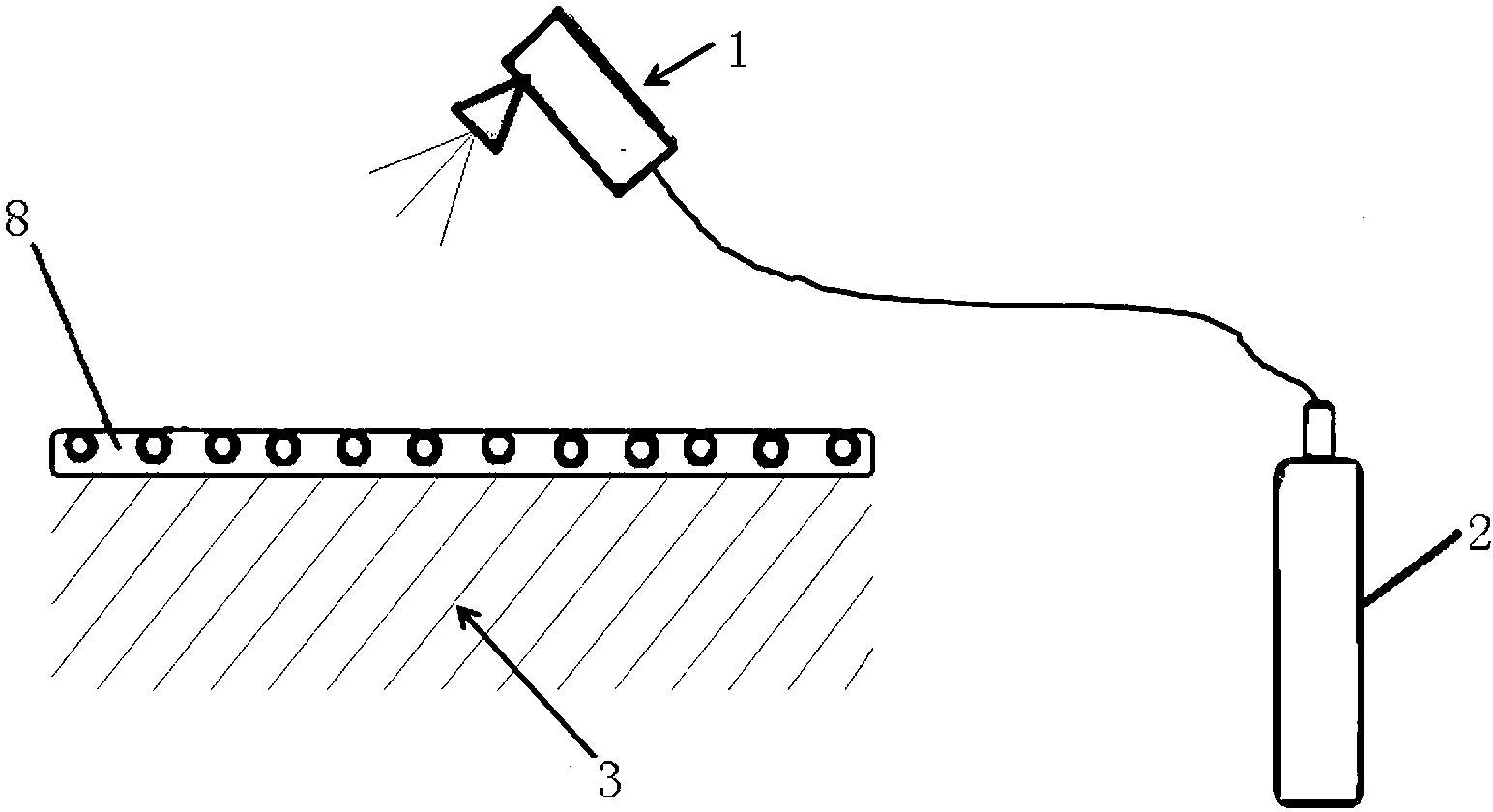

[0022] A fluorescent oil flow friction field measurement device, including a CCD camera 4, an LED light source 5, a computer 6, a wind tunnel 7 for testing and spraying equipment;

[0023] The spraying equipment is composed of a spray gun 1 and a high-pressure gas source 2, and the high-pressure gas source is a nitrogen source;

[0024] The CCD camera 4 and the LED light source 5 are installed outside the observation window of the wind tunnel 7 for the test respectively, and the LED light source and the model test piece 3 which is arranged in the wind tunnel 7 for the test can be irradiated, and the CCD camera 4 can effectively capture The image information of the model test piece 3; the LED light source 5 is connected to the peripheral power supply through wires, the information output terminal of the CCD camera 4 is connected to the corresponding interface of the computer 6 through the cat6 network cable, and the medium inlet of the spray gun 1 is connected to the high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com