Waterproof board installation trolley for tunnel

A technology for waterproofing boards and tunnels, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of the circumferential tightness of the waterproofing board, high longitudinal flatness, low equipment versatility, damage to the waterproofing board, etc., and achieve the operation coverage. Large, compact structure and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

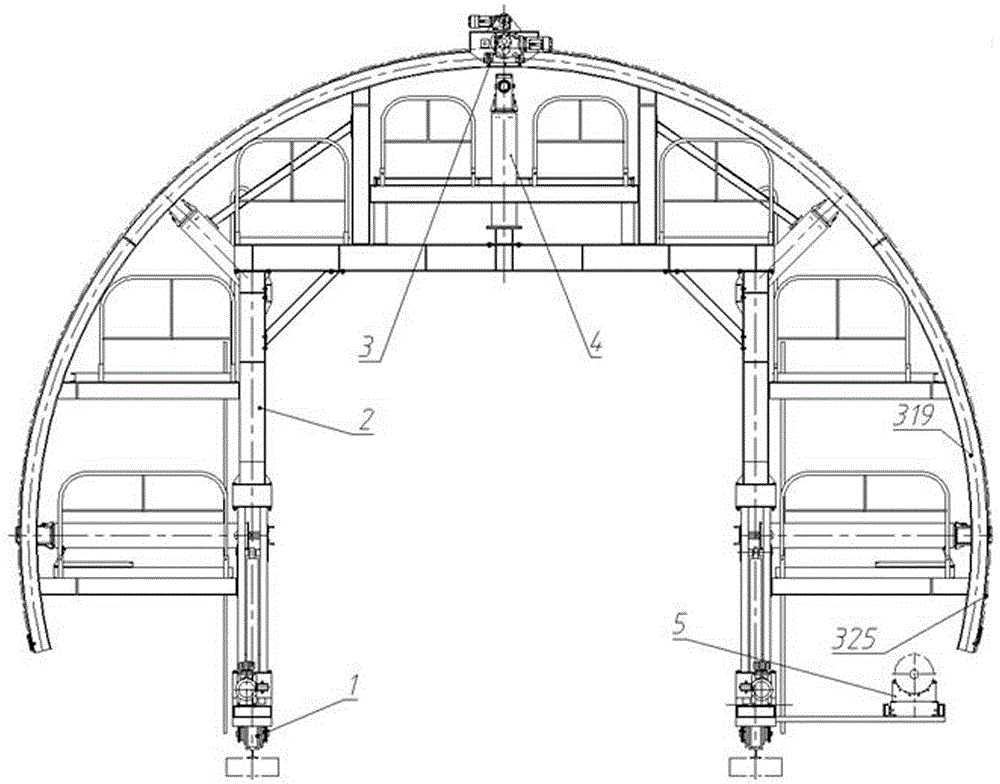

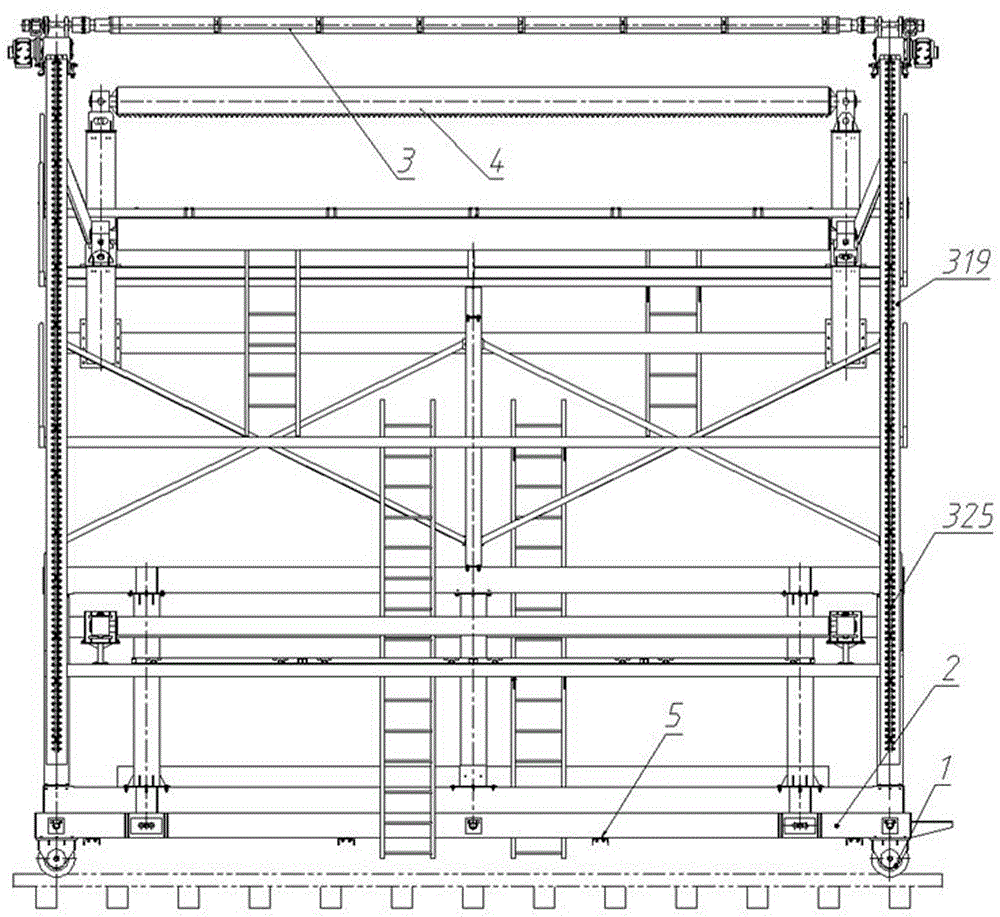

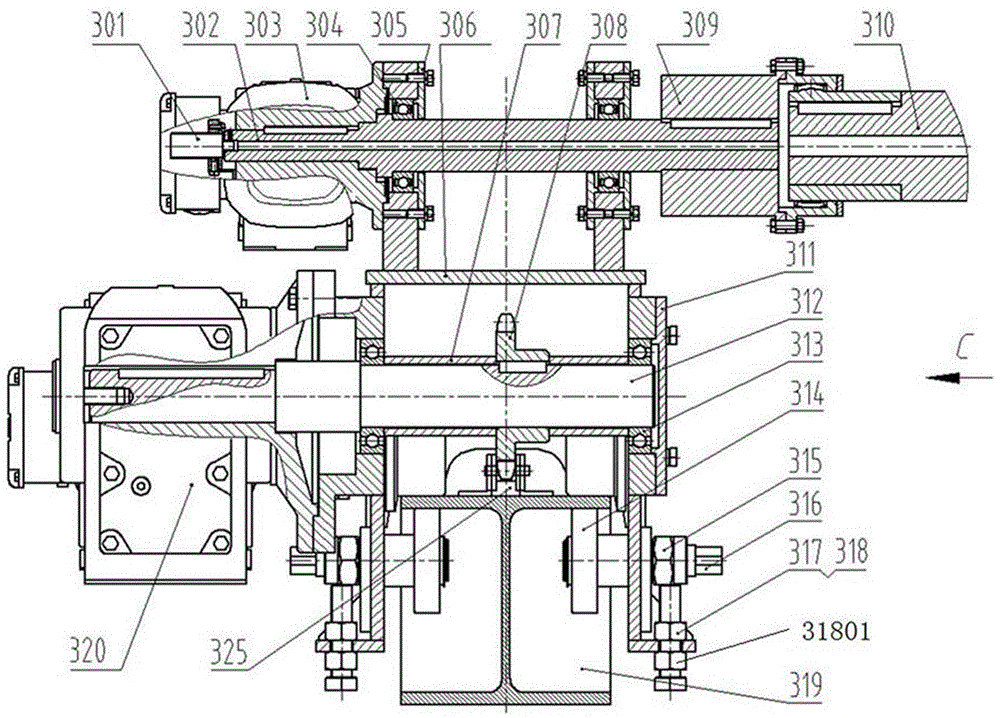

[0053] The present invention provides a figure 1 , figure 2 The trolley for installing the waterproof board 6 shown in the tunnel includes a main body frame 2 and a traveling mechanism 1. Arc-shaped crawling tracks 319 are installed at both ends of the main body frame 2, and the running mechanism 1 is installed at the bottom of the main body frame 2. It also includes a winding and unfolding mechanism 3, a jacking mechanism 4 and a positioning mechanism 5; the jacking mechanism 4 is fixedly connected with the main body frame 2, and the jacking mechanism 4 is used to push the unfolded waterproof board 6 or the bound steel bar 7 Lift it in place; the positioning mechanism 5 is connected to the lower end of the main frame 2 gantry, and the positioning mechanism 5 uses a drawer-type structure to place the rolled waterproof board 6, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com