Wood floor edge closing-up device

A technology of wooden floor and fixed board, applied in the direction of construction and building structure, can solve the problems of affecting the laying quality of wooden floor, easy to damage the floor, low efficiency, etc., to ensure the efficiency and laying quality, prolong the service life, and ensure the stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0022] The invention provides a wood floor edge trimming device, the working principle of which is to use the L block to hook the edge of the wood floor, use the hand grip to quickly move from the front block to the rear block along the beam, and hit the rear block , to drive the L-shaped block to exert force on the edge of the wooden floor, so that the wooden floors gradually move closer together, eliminating the gaps that exist when laying the corner wooden floor, ensuring the quality of the wooden floor and improving the efficiency of the wooden floor.

[0023] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

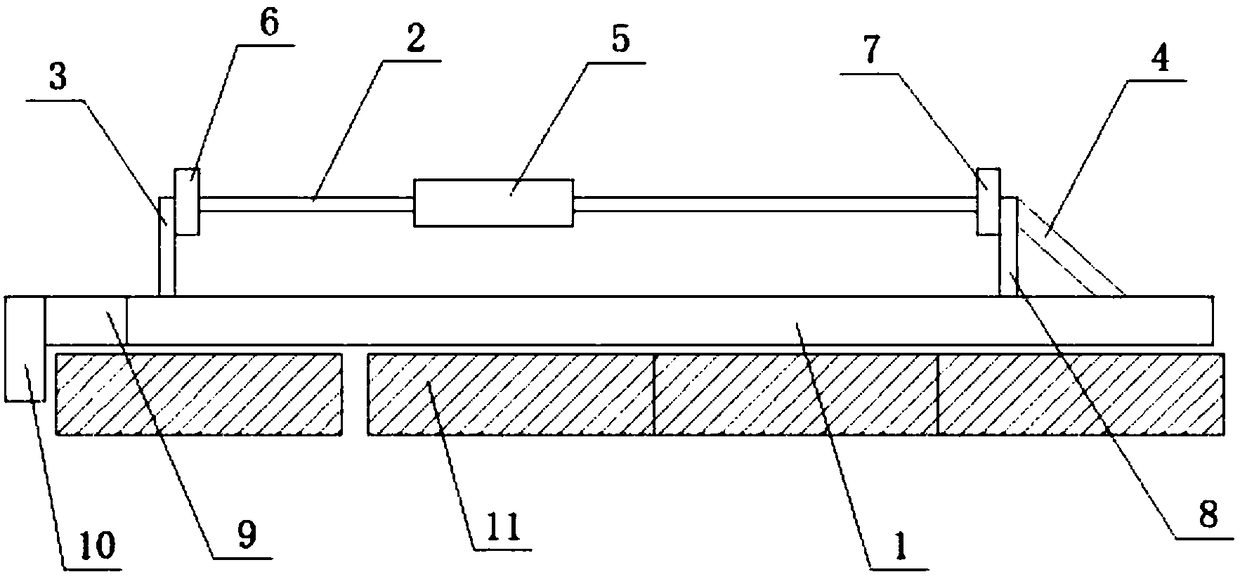

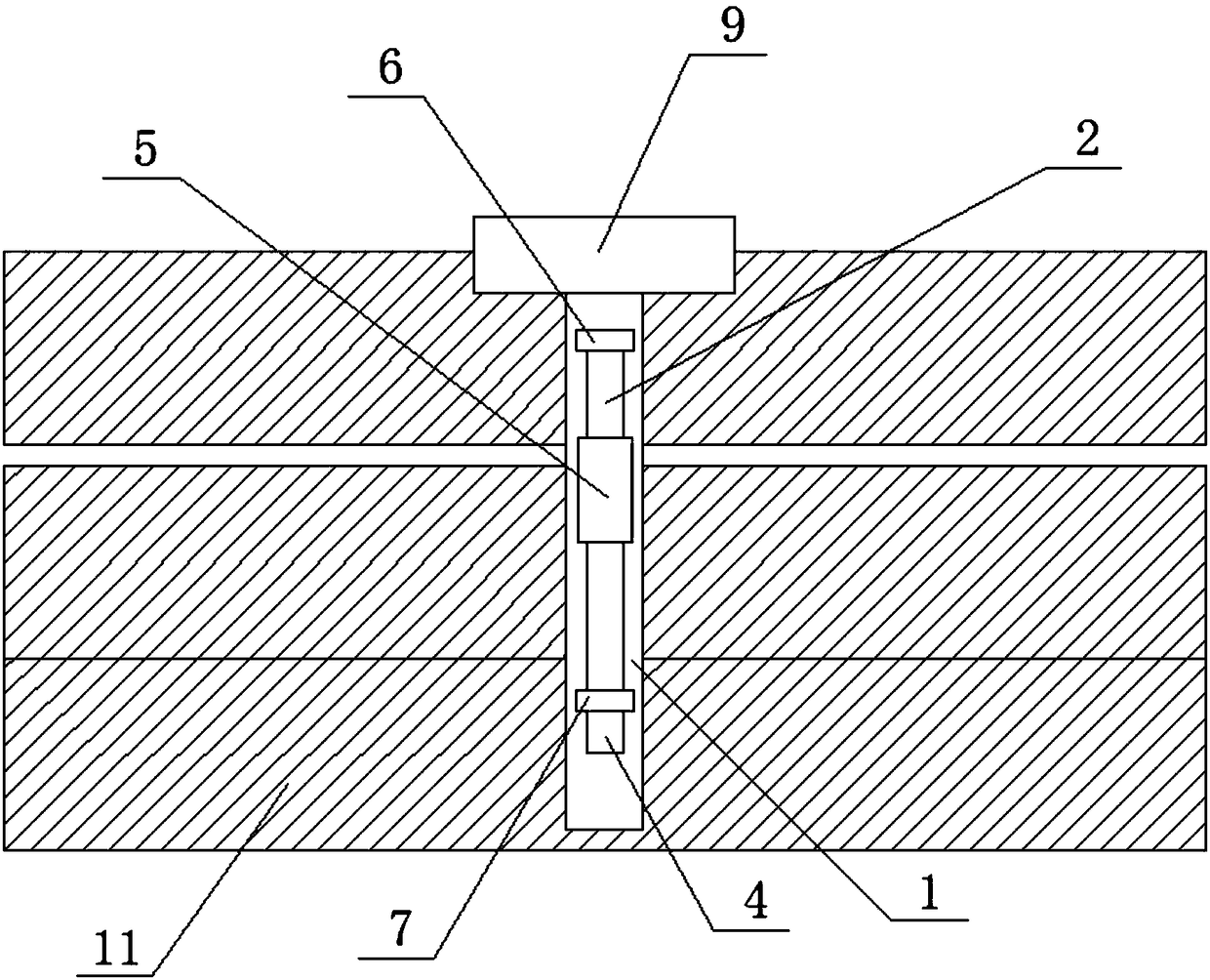

[0024] Such as figure 1 and figure 2 As shown, a wood floor edge trimming device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com