Rotary curved surface structure composite material additive manufacturing device

A composite material and surface structure technology, applied in the directions of manufacturing auxiliary devices, additive manufacturing, manufacturing tools, etc., can solve the problems of low utilization rate of fiber mechanical properties, and achieve the effect of ensuring the laying quality and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

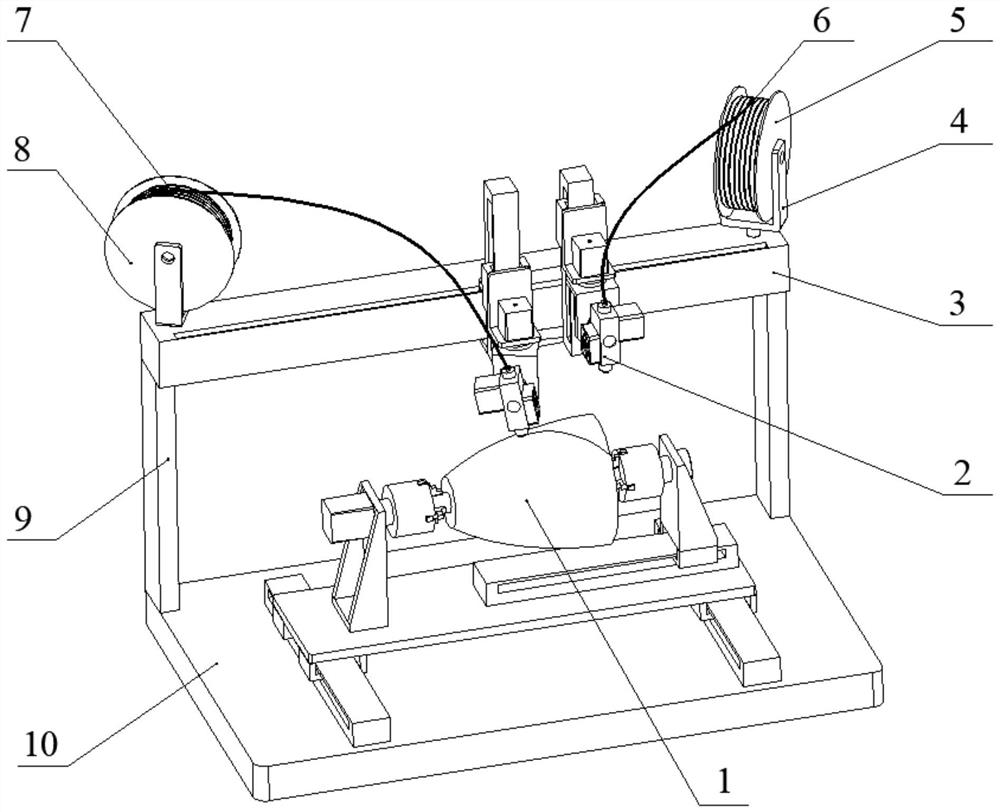

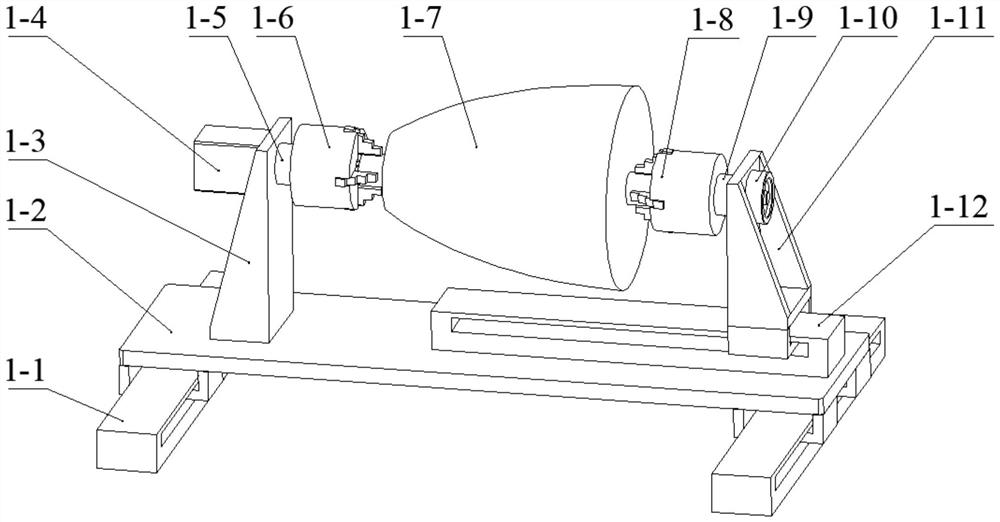

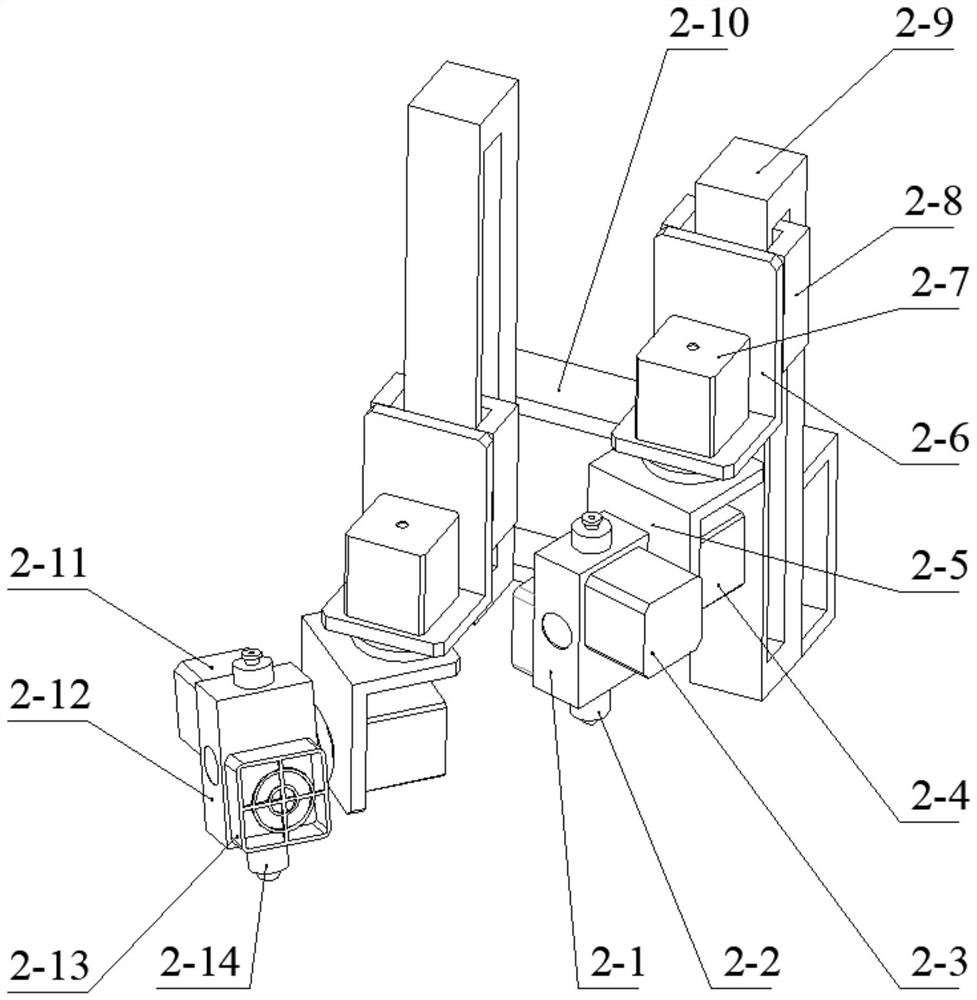

[0021] Such as Figure 1-3 As shown, the present invention provides a composite material additive manufacturing device with a rotary curved surface structure, including a device frame structure, a mandrel clamping drive device 1, a fiber printing nozzle 2-14, a resin printing nozzle 2-2, and nozzle position and attitude adjustment Device and material extrusion printing device 2; the bottom plate 10 provided with the frame structure of the device is provided with a mandrel clamping drive device 1; the device frame structure above the mandrel clamping drive device 1 passes through the position and posture adjustment device of the nozzle and the fiber printing device respectively. The nozzle 2-14 is connected to the resin printing nozzle 2-2, and the fiber printing nozzle 2-14 and the resin pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com