Mud flat machine for prefabricated waterproof roll

A technology of waterproofing membrane and tidal coating machine, which is applied in the processing of building materials, roads, and road repairs, etc., can solve the problems of poor waterproof quality, uneven laying of waterproof coatings and waterproofing membranes, and non-compliance with standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

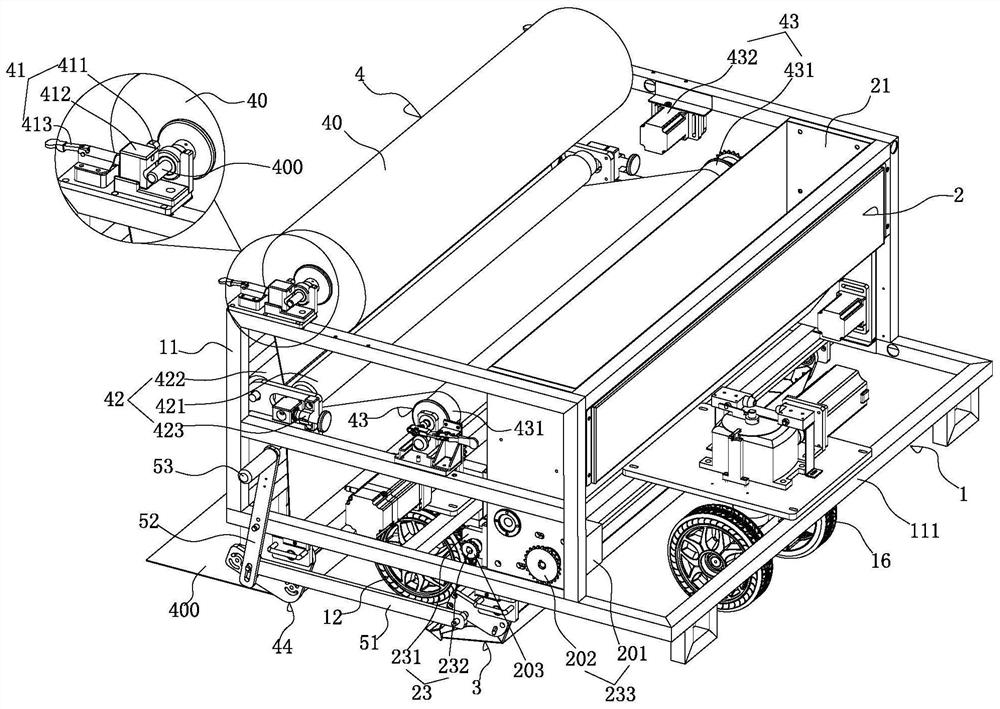

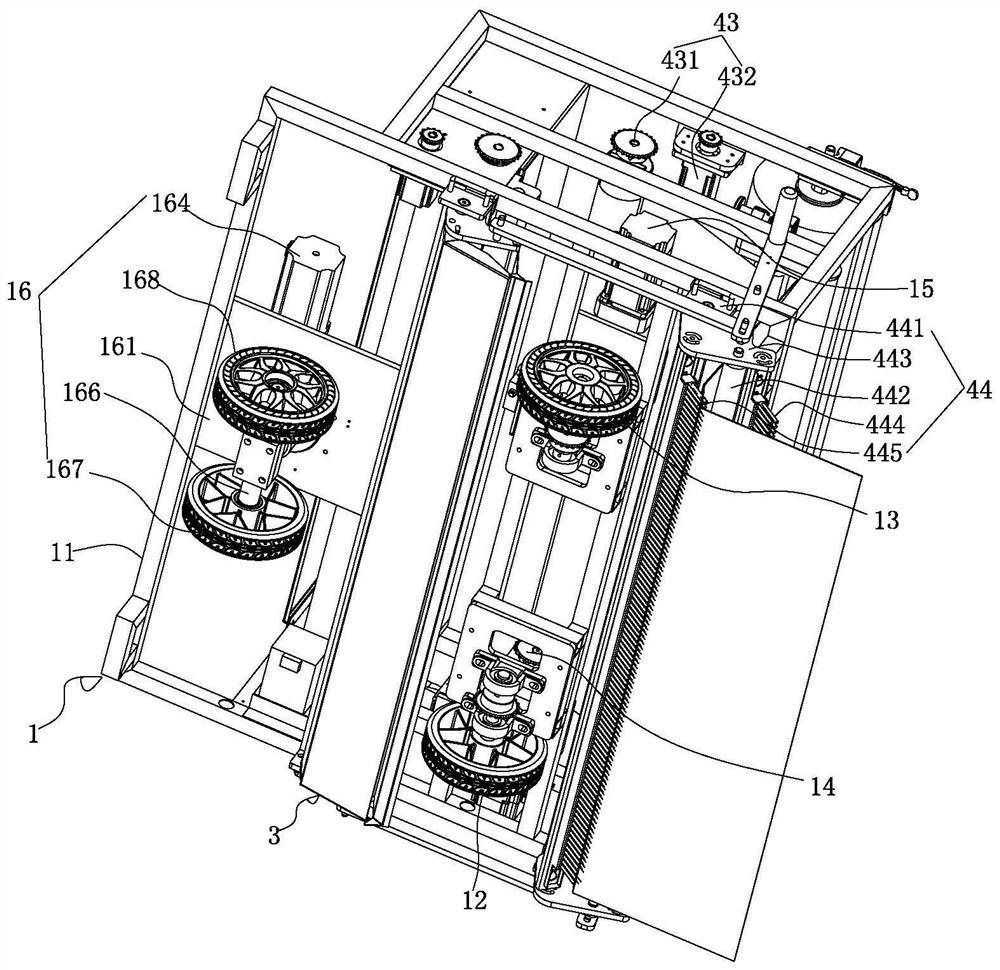

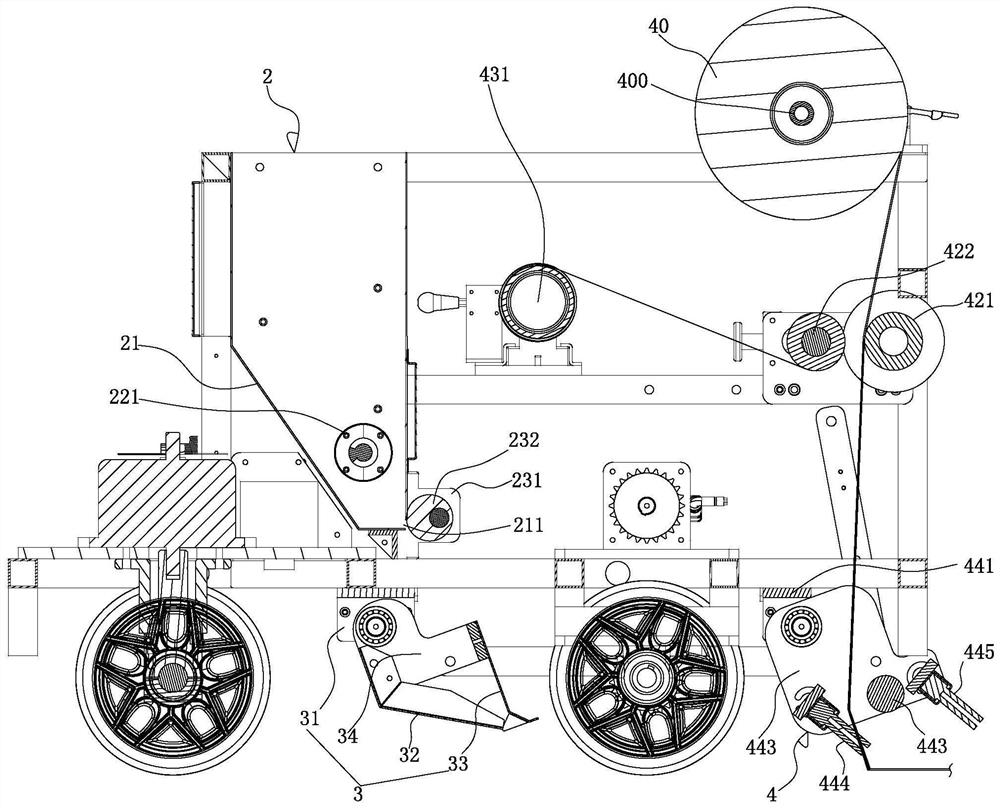

[0031] See Figure 1-13 Shown, it is a kind of prefabricated waterproof coiled beach machine, which includes: a remote-controlled walking trolley 1; a slurry extruding device 2, which includes a hopper 21 installed on the walking trolley 1 and used for loading slurry and installed on the The lower end of the inner cavity of the hopper 21 is used to extrude the slurry along the strip-shaped discharge port 211 of the hopper 21, and the extrusion mechanism 22 is installed at the strip-shaped discharge port 211 of the hopper 21 and is used to control the strip-shaped discharge. The on-off valve 23 of the size of the feed port 211; the drag scraper thickness adjustment device 3, which includes a bracket 31 installed in the walking trolley 1 and located below the slurry extrusion device 2, and is rotatably installed on the bracket 31 The first rotating fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com