Spliced floor tile, preparation technology and paving technology of spliced floor tile

A technology of floor tiles and ceramic tiles, which is applied to floors, buildings, building structures, etc., can solve the problems of material cost, high time cost and labor cost, floor tiles cannot be recycled and reused, waste of material resources and construction waste, etc., to reduce construction costs. Waste of time and material resources, good performance, and the effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

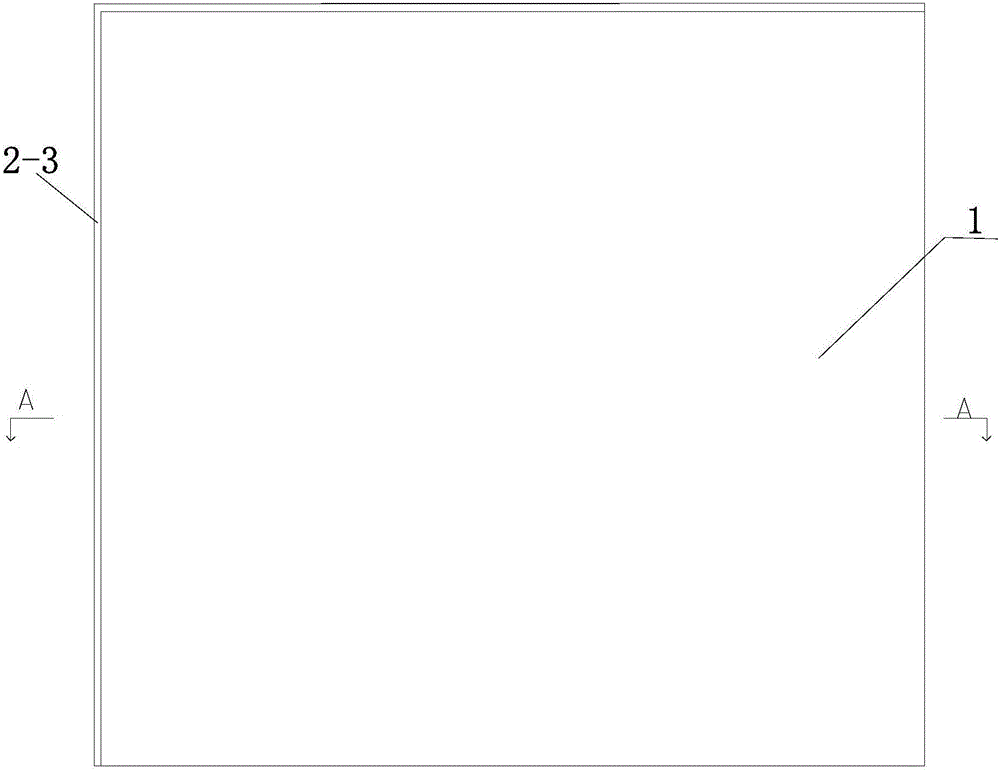

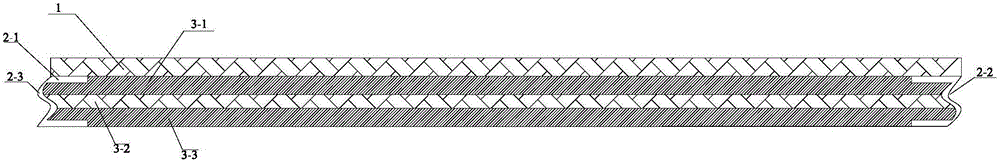

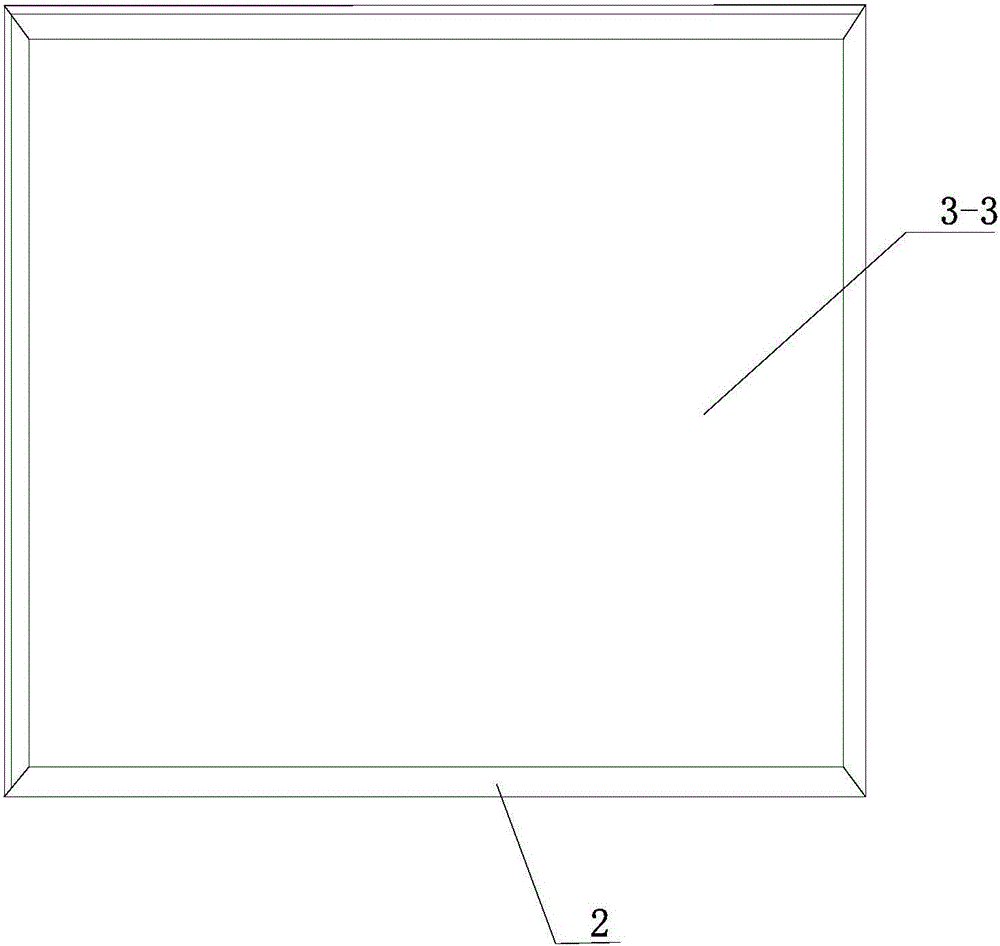

[0034] Embodiment one: if figure 1 , 2 3. Shown in 3: a mosaic floor tile, which includes a tile 1 and a chassis whose shape and size match the tile 1, the lower surface of the tile 1 and the upper surface of the chassis are pasted together, and the sides of the chassis are provided with mutual Matching snap-lock construction. like figure 1 , shown in 2, the tiles are conventional quadrilateral tiles, and of course other polygon tiles can also be used. Through the design of the locking splicing structure, the floor tiles of the present invention are endowed with splicing and detachable functions, making the floor tiles of the present invention a kind of splicable floor tiles. It not only facilitates the splicing of the splicing floor tiles, but also facilitates the dismantling of the splicing floor tiles, so that the splicing floor tiles have the function of being recyclable.

[0035] The chassis includes a frame A2 and fillers fixed in the frame A2, the frame A2 and the f...

Embodiment 2

[0042] like Image 6Shown: a kind of preparation technology of described mosaic floor tile, it comprises the following process steps:

[0043] ①Preparation of moulds for splicing floor tiles: select a frame B4 whose shape and size match the tile 1, and respectively fix the angular fixing pieces 5 on the corners of the upper surface of the frame B4, the shape and size of the corners of the fixing pieces 5 are the same as the corners of the frame B4 Matched, the inner surface of the fixed piece 5 is flush with the inner surface at the corner of the frame B4; Figure 5 shown.

[0044] Of course, the frame B4 may not be provided with the fixing sheet 5, but when the fixing sheet 5 is not provided, it must be ensured that the thickness of the frame B4 is greater than that of the ceramic tile.

[0045] ② Place the tile 1 in the frame B4 with the surface facing down and the bottom facing up;

[0046] ③ connecting the strip profiles 2-1 to each other in turn and fixing them to form...

Embodiment 3

[0053] Embodiment 3: the general process of embodiment 3 of the present invention is the same as that of embodiment 2. The main difference is the difference between steps 8 and 9. The process of step 8 in embodiment 3 is: the product obtained in step 7 is maintained with frame B4 4 days; the process of step ⑨ in Example 3 is: remove the frame B4, then continue to maintain the obtained product for 4 days, and finally dry it naturally to obtain the mosaic floor tile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com