Cable ground laying device

A cable and ground technology, used in the field of cable ground laying devices, can solve the problems of cable surface wear, affecting power supply reliability, cable resistance, etc., achieve good flexibility and wear resistance, avoid power supply reliability, and prevent excessive weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following is attached Figure 1-11 The application is described in further detail.

[0048] The embodiment of the present application discloses a ground cable laying device.

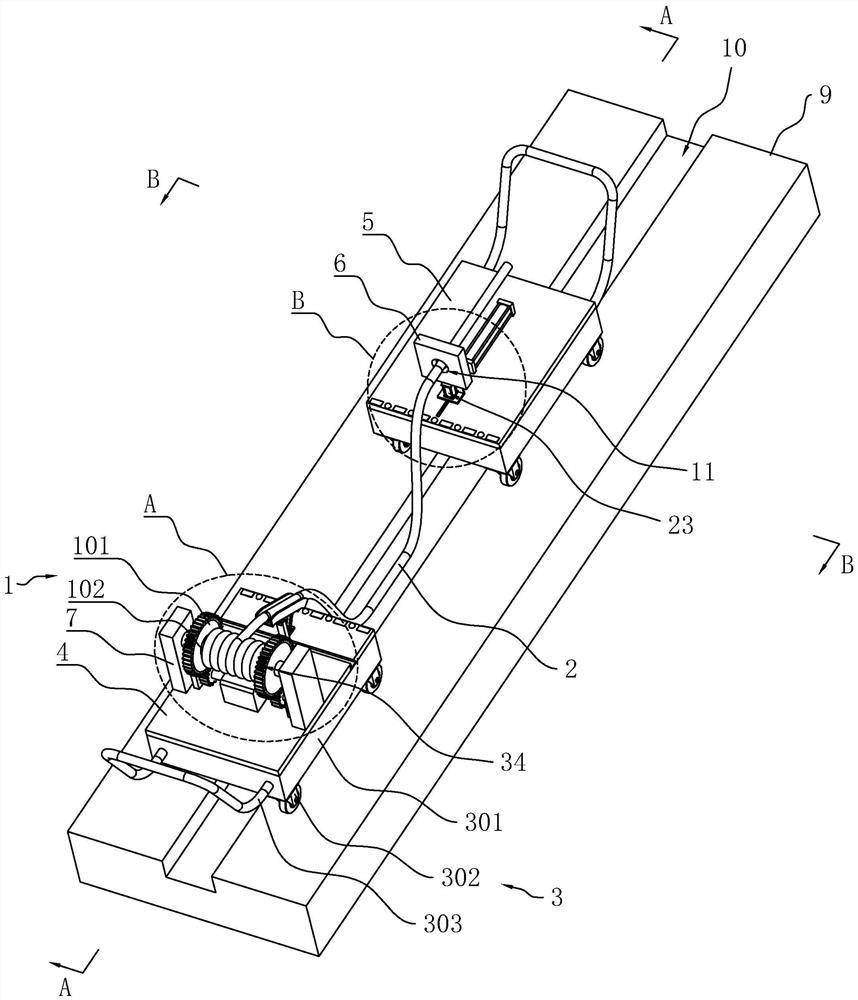

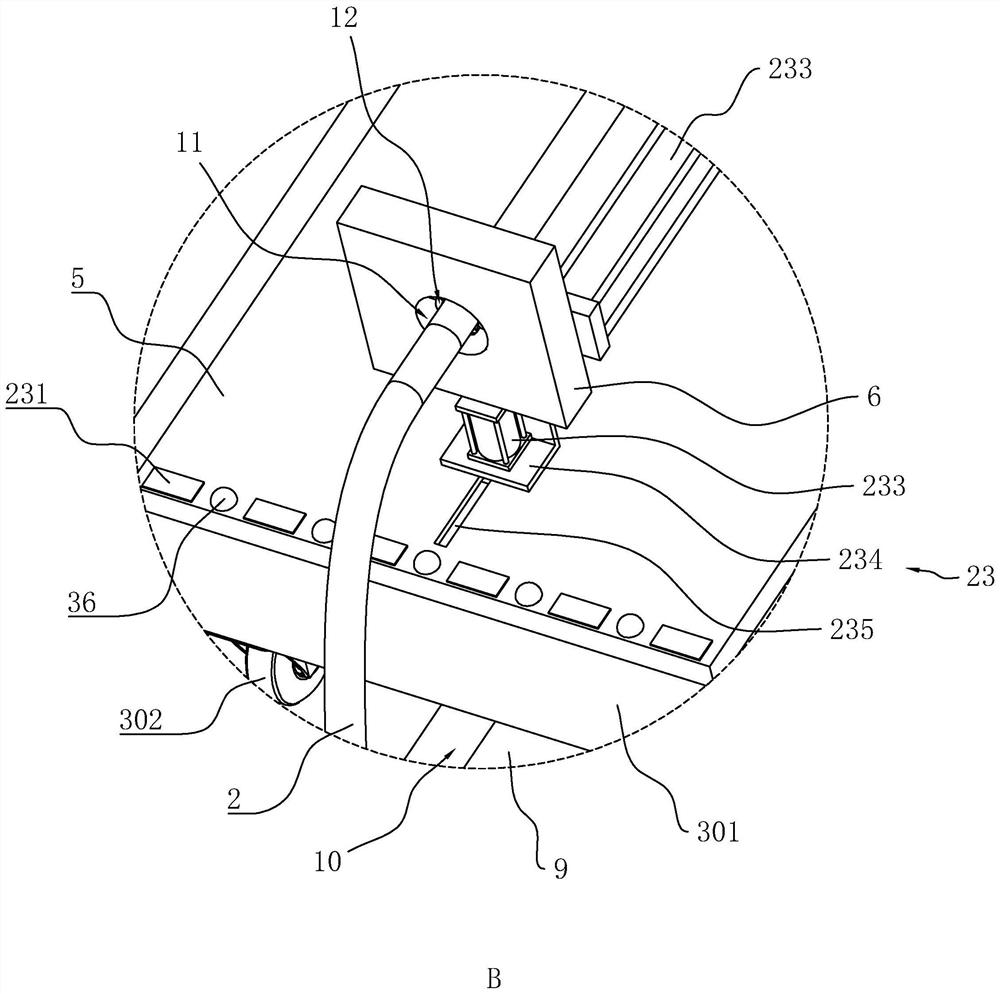

[0049] refer to figure 1 , a cable laying device on the ground, comprising two trolleys 3, a cable trench 10 is dug on the ground 9, the two trolleys 3 are erected on the ground 9, the trolley 3 is located above the cable trench 10, and the trolley 3 includes a base 301, Universal wheels 302 arranged at the four corners of the lower surface of the base 301 and hand push rods 303 arranged on the side walls of the base 301 .

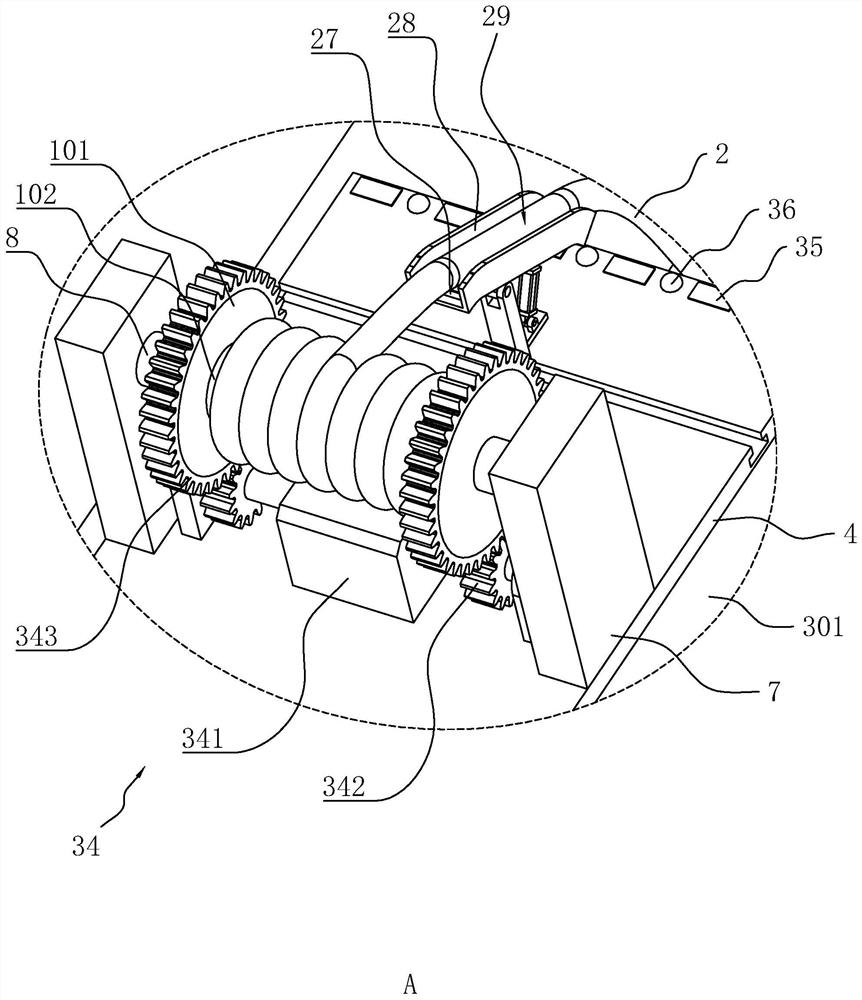

[0050] refer to figure 1 with figure 2 , the base 301 of one of the trolleys 3 is fixedly installed with a pay-off seat 4, and the upper surface of the pay-off seat 4 is provided with two relative support platforms 7, and the opposite side walls of the two support platforms 7 are all rotatably connected with mounting columns 8. A cable reel 1 is provided between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com