Automatic fiber placing device for placing fibrous composite material

A fiber composite material and automatic laying technology, which is applied in the field of automatic laying equipment, can solve the problems of inability to compaction, poor laying accuracy, and inability to apply prepreg by pressing rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

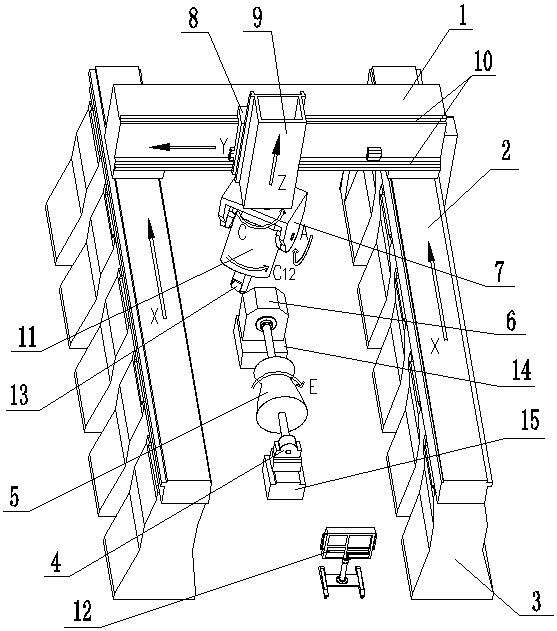

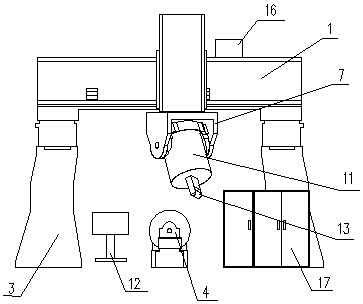

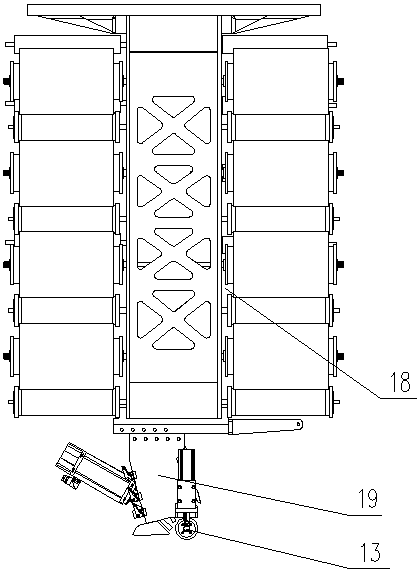

[0031] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown in and , this embodiment includes two columns 3 arranged symmetrically, two longitudinal beams 2 installed on the two columns 3, a transverse beam 1, a sliding seat 8, a ram 9, a rotary device 7, including a control servo motor A, a servo Motor B, servo motor C, servo motor D, C-axis rotary mechanism, C1-axis rotary mechanism, A-axis rotary mechanism and the operation control system of the brake device, the power control device of the infrared heating device, and each on the silk laying head device The control system of separate winding, tensioning, clamping, shearing and re-feeding control devices for filament bundles, including the creel 18, the laying head 19, the laying head pressure roller 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com