Fabricated type cable through-wall fixing device and cable through-wall laying construction method

A fixed device and prefabricated technology, used in cable laying equipment, electrical components, etc., can solve the problems of easily damaged concrete walls, delayed power transmission time, long construction period, etc., to improve laying efficiency, ensure normal operation, The effect of low cost price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

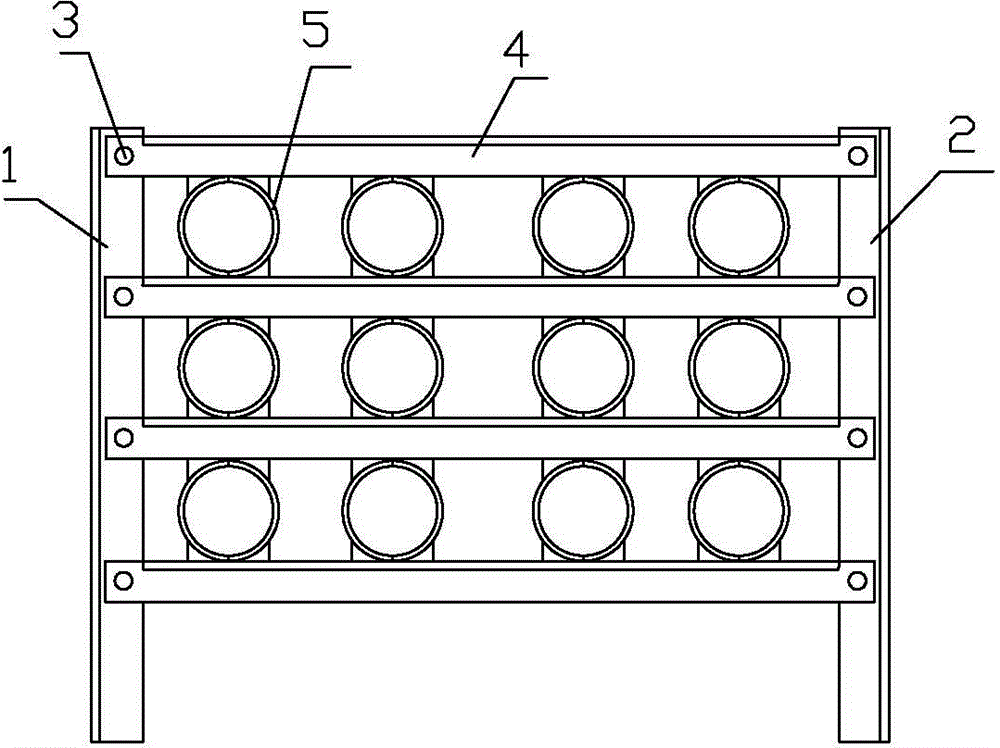

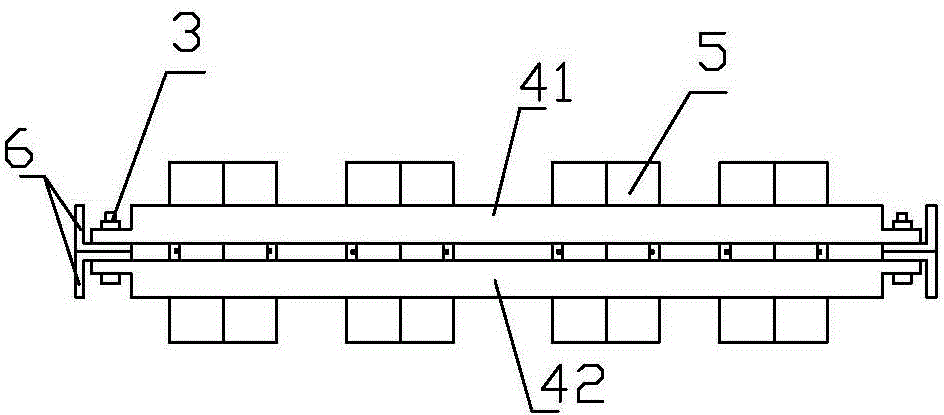

[0021] refer to figure 1 , figure 2 , image 3 Make the invention. The assembled cable wall fixing device includes a left bracket 1 and a right bracket 2, and is characterized in that a cross arm 4 is fixed between the left bracket 1 and the right bracket 2 by bolts 3, and two adjacent cross arms A combination sleeve 5 is provided between the 4.

[0022] The cross-sections of the left bracket 1 and the right bracket 2 are both "T" shaped.

[0023] Both the left bracket 1 and the right bracket 2 are composed of two angle steel bars 6 whose cross sections are at right angles.

[0024] The cross arm 4 is composed of a front cross arm 42 and a rear cross arm 41 arranged in parallel, and is clamped on both sides of the left bracket 1 and the right bracket 2 .

[0025] The front cross arm 42 and the rear cross arm 41 are also made of angle steel bars with a right angle cross section.

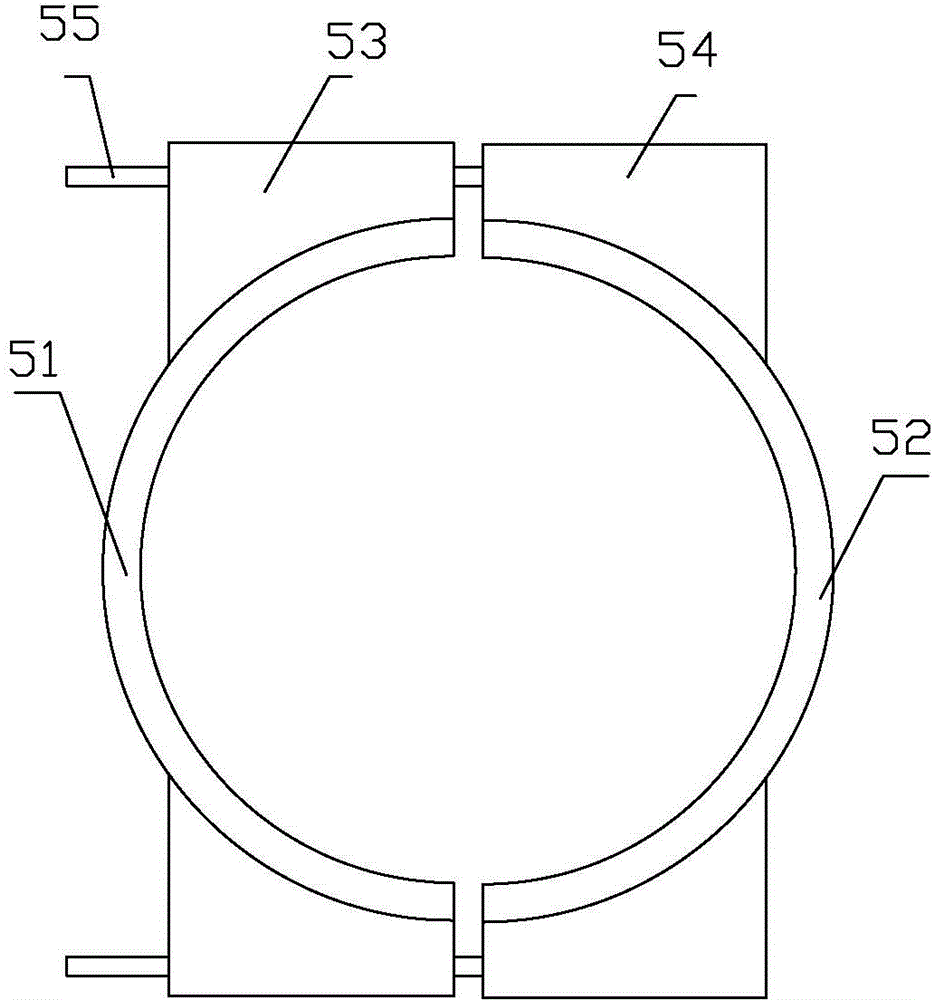

[0026] The combined casing 5 is composed of a left semicircular casing 51, a right semicirc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com