Pipe bunching device

A clustering device and tube technology, applied in packaging, packaging recycling, transportation and packaging, etc., can solve the problems of not adapting to the requirements of rapid laying, high labor intensity, and relying on manpower for loading and unloading and handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

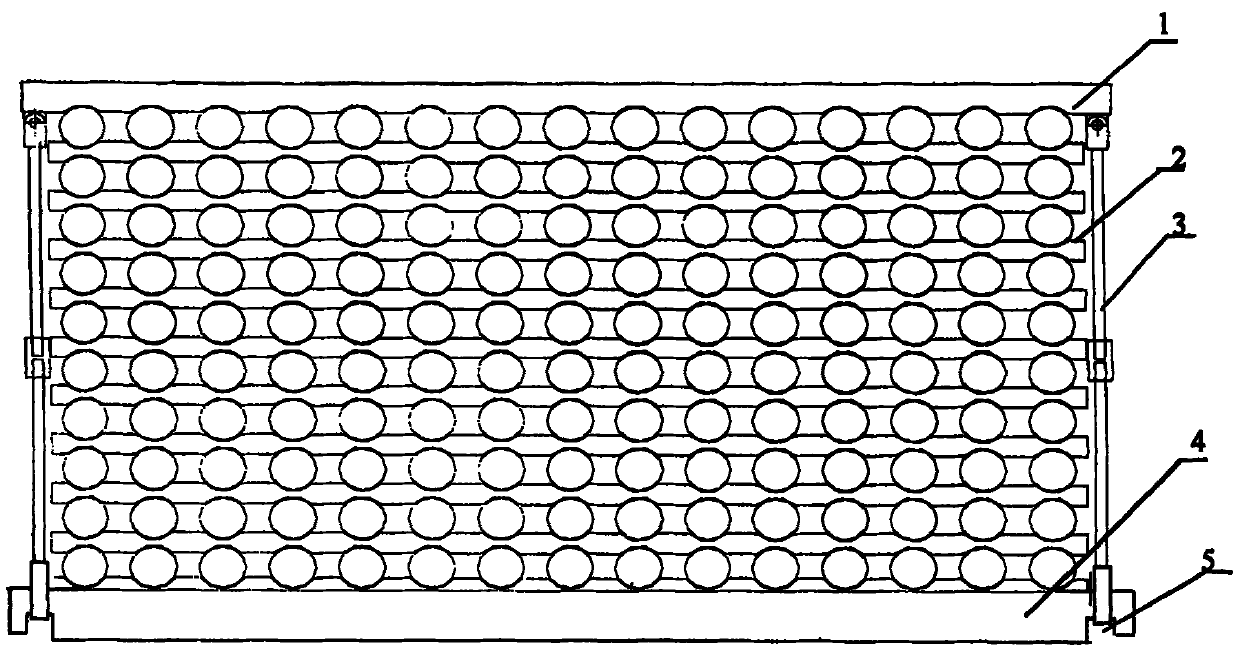

[0021] The following is a specific example of a clustering device that cooperates with a pipe laying vehicle and describes the structure of the present invention in detail in conjunction with the accompanying drawings:

[0022] 1. Technical index of cluster device

[0023] 1.1 self weight

[0024] The upper beam is 26kg, the lower beam is 39kg, the tie rod is 4.2kg / piece, and the isolation positioning device is 10kg / piece. The total self-weight of each cluster device is about 250kg.

[0025] 1.2 Mechanical properties

[0026] Mechanical and mechanical properties: the maximum net weight of the steel pipe is 63000N, and the maximum lifting acceleration is 1m / s 2 , the maximum deflection of the lower beam is 6.8mm, the maximum deflection of the upper beam is 16.1mm, the maximum stress of the tie rod is 37MPa, and the maximum stress of the thread is 12MPa.

[0027] 2. Structure:

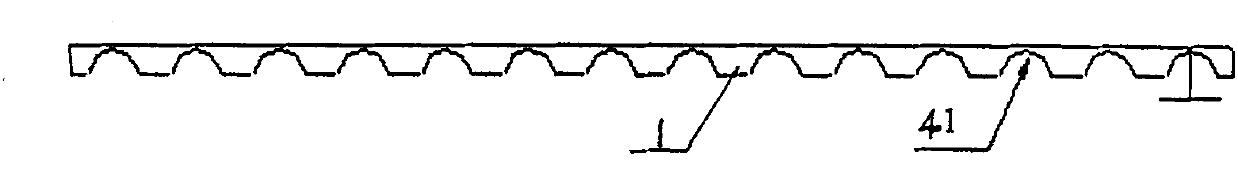

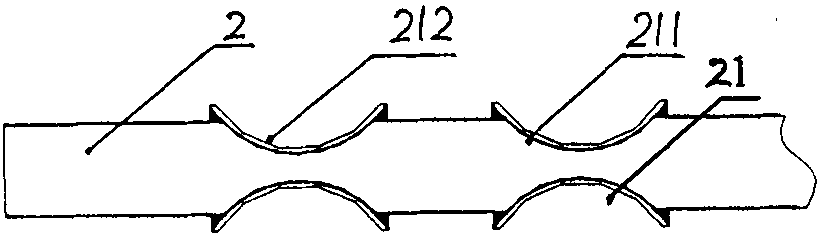

[0028] see figure 1 , the cluster device is mainly composed of four parts: the upper beam 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com