Foamed warm mix asphalt mixture and preparation method thereof

A technology of warm-mix asphalt and foamed asphalt, which is applied in the field of foamed warm-mix asphalt mixture and its preparation, to achieve the effects of reducing carbon dioxide emissions, improving laying efficiency, and prolonging the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

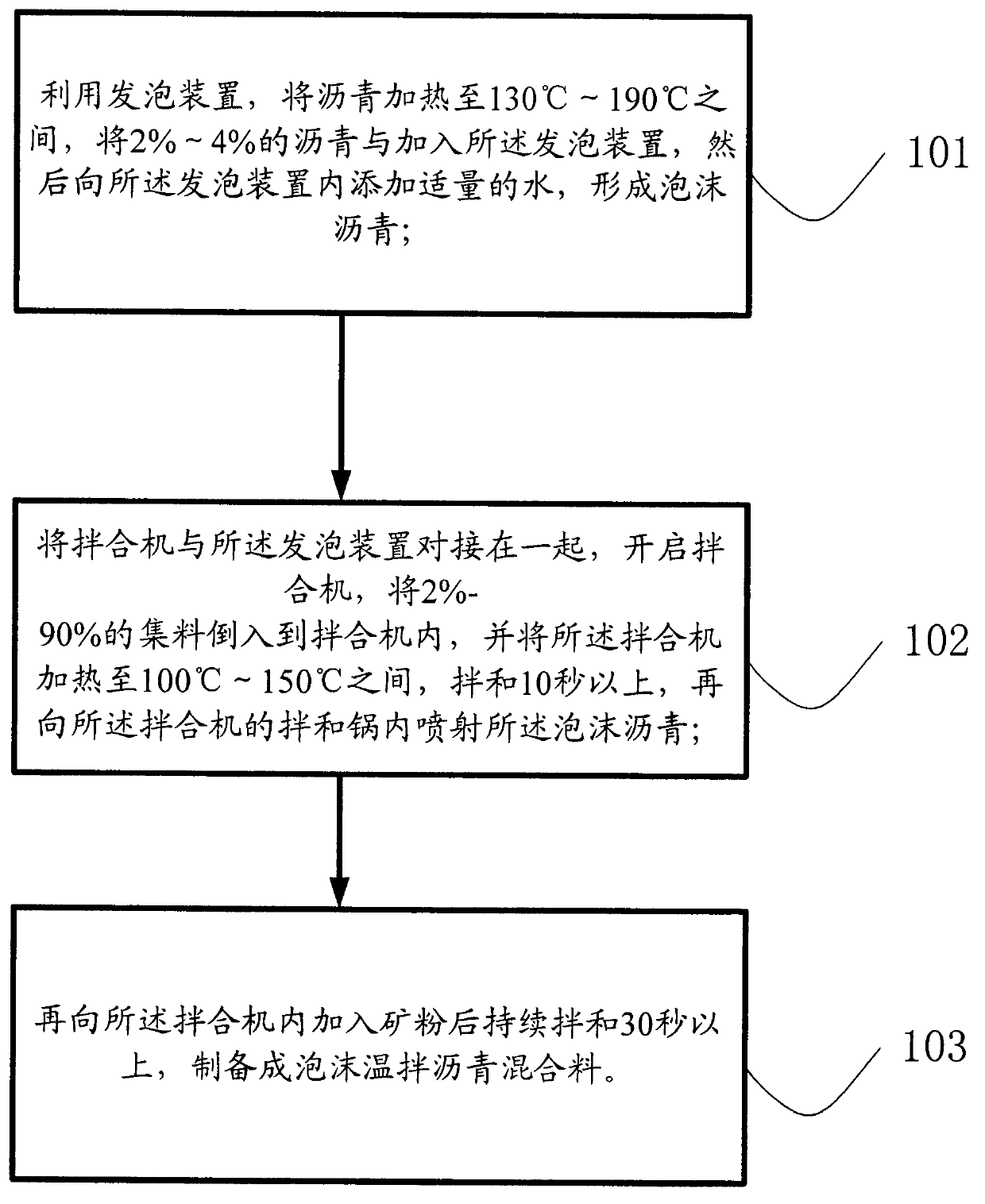

Method used

Image

Examples

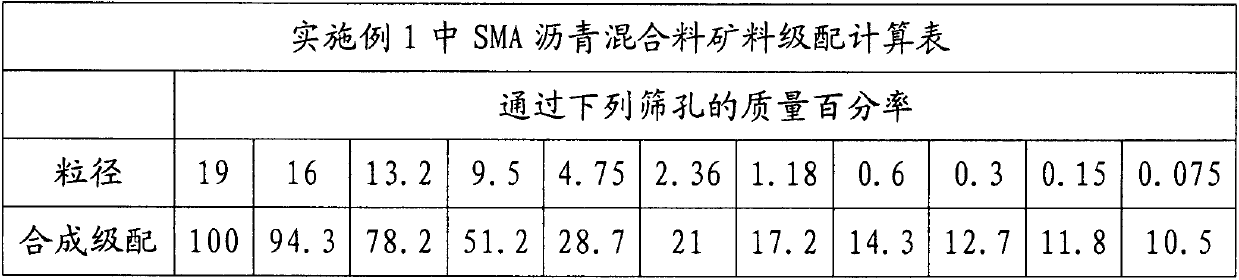

Embodiment 1

[0059] Material composition:

[0060] Aggregate: 0.895 tons;

[0061] Mineral powder: 0.105 tons;

[0062] Rubber modified asphalt: 0.059 tons;

[0063] Water: 0.0012 tons;

[0064] Wood fiber: 0.0024 tons.

[0065] The specific steps for preparing foamed asphalt warm mix are:

[0066] Heat the aggregate and mineral powder to 130°C respectively;

[0067] Heat the rubber-modified asphalt to 175°C;

[0068] Use the foaming device to inject water vapor into the asphalt to form foamed asphalt;

[0069] Finally, mix the aggregate and wood fiber in the mixing pot for 15 seconds, spray the foamed asphalt into the mixing pot and mix for 10 seconds, add mineral powder and mix for 30 seconds; prepare foamy warm asphalt mixture.

[0070] Obviously, the proportions of the above-mentioned components can be appropriately adjusted according to specific needs, and the above-mentioned component proportions cannot be used as the final basis. The performance of the foamed asphalt warm mix...

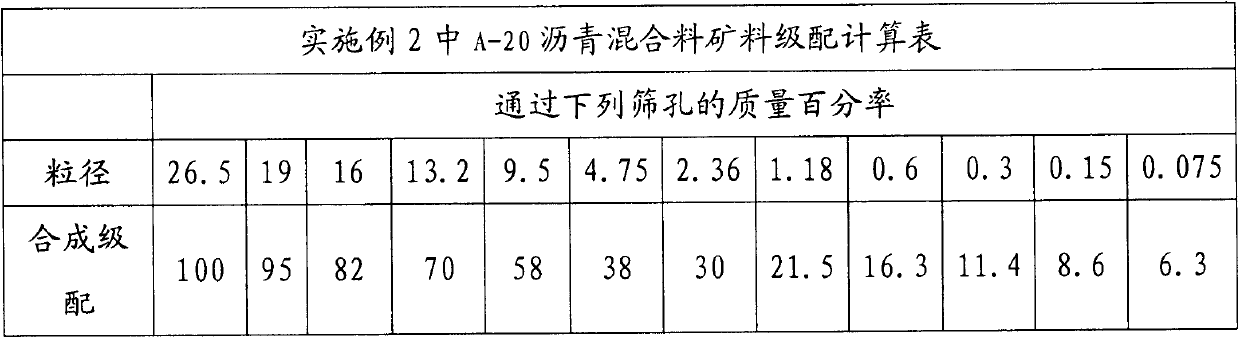

Embodiment 2

[0075] Material composition:

[0076] Aggregate: 0.937 tons;

[0077] Mineral powder: 0.063 tons;

[0078] Asphalt: 0.046 tons;

[0079] Water: 0.00092 tons.

[0080] The specific steps for preparing foamed asphalt warm mix are:

[0081] Heat the aggregate and mineral powder to 130°C respectively;

[0082] Heat the asphalt to 170°C;

[0083] Use the foaming device to inject water vapor into the asphalt to form foamed asphalt;

[0084] Finally, mix the aggregate evenly in the mixing pot, spray the foamed asphalt into the mixing pot and mix for 2 minutes, then add the heated mineral powder and mix for 2 minutes to prepare foamy warm asphalt mixture.

[0085]

[0086] Obviously, the proportions of the above-mentioned components can be adjusted appropriately according to specific needs, and the above-mentioned component proportions cannot be used as the final basis. The properties of the foamed asphalt warm mix mixture in the present invention are shown in Table 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com