Shield machine

A shield machine and shell technology, which is applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of incapable of cambered pipes, easy wear of cutting tools, low cutting efficiency, etc. Damage, high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

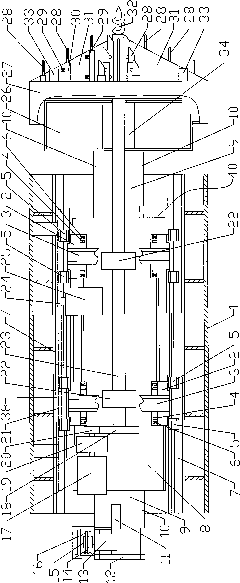

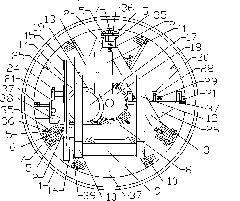

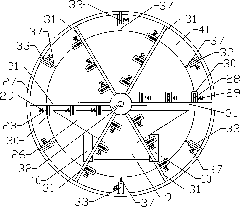

[0021] Example: as attached figure 1 And attached figure 2 As shown, the shield machine includes a cylindrical casing 1, a cutting device is provided at the front of the casing 1, and three guide rails 7 are arranged inside the casing 1, and three guide rails 7 are provided with shafts that can move along the axis of the casing 1. To the sliding seat 40 that slides back and forth, the bottom of the sliding seat 40 is fixedly connected with a conveying device, and the upper part of the sliding seat 40 is provided with a cutting power transmission device and a feeding power transmission device, and the cutting power transmission device is connected with the cutting device.

[0022] Sliding seat 40 comprises two polygonal supports, and polygonal support is triangular support 3, and two supports 3 are connected by channel steel, and the three corners of support 3 are all provided with the sliding adjusting device that cooperates with guide rail 7, and the bottom of support 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com