Full-automatic laying equipment and method for ceramic tiles

A fully automatic tile technology, which is applied in the direction of construction and building construction, can solve the problems of high construction cost, poor flatness, large error, etc., and achieve the effect of reducing labor intensity, reducing construction cost and improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

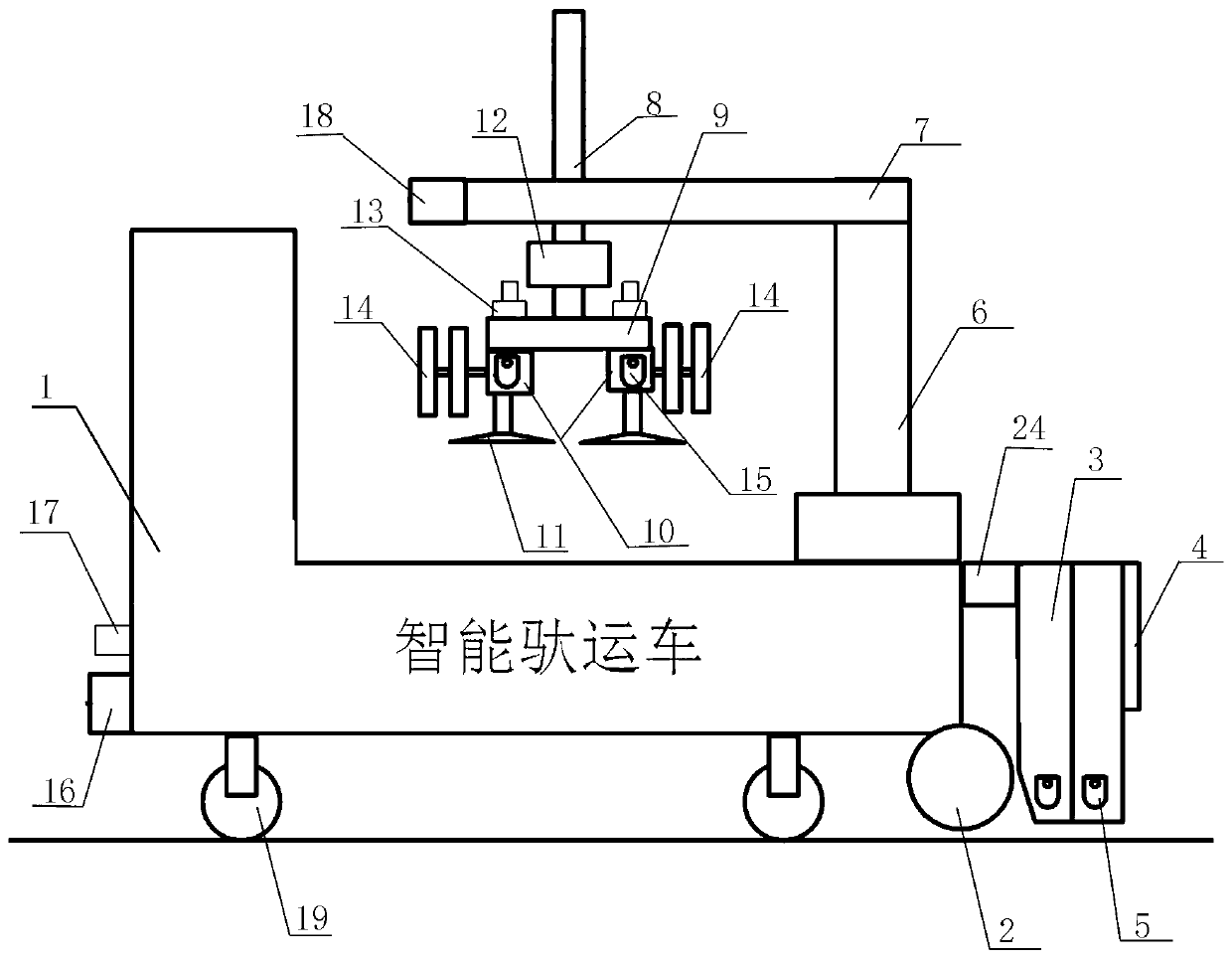

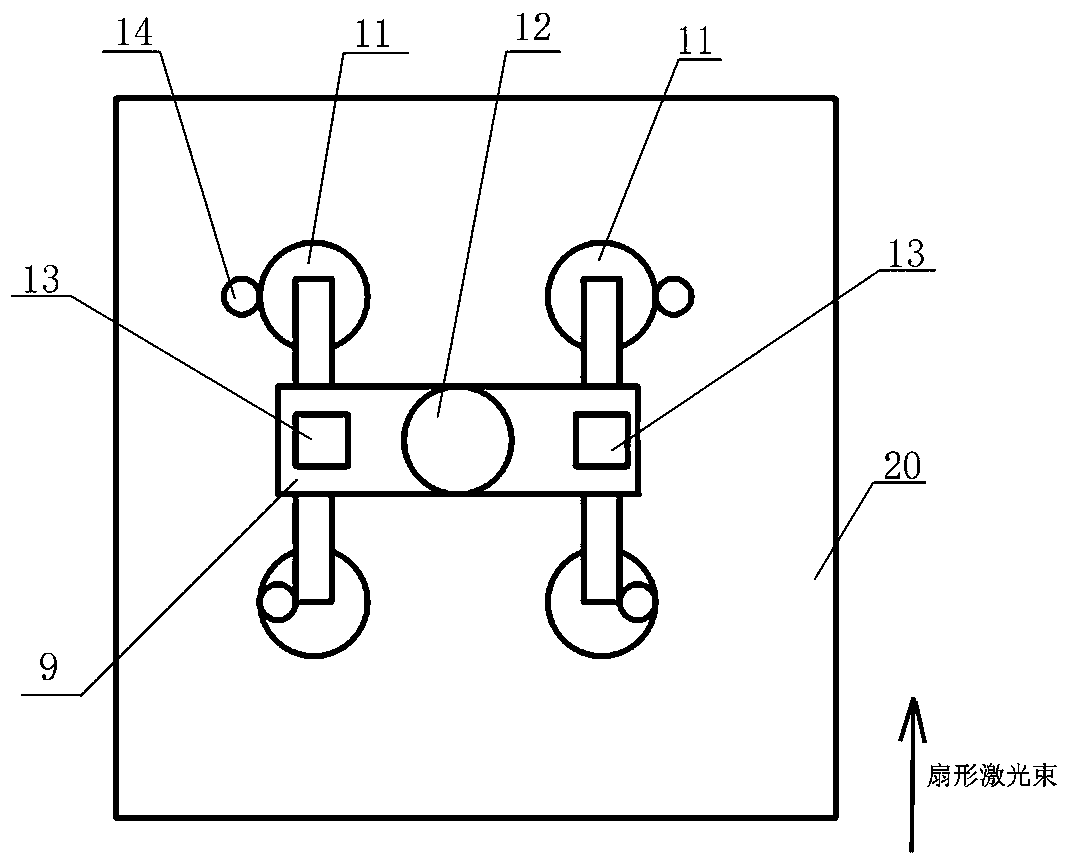

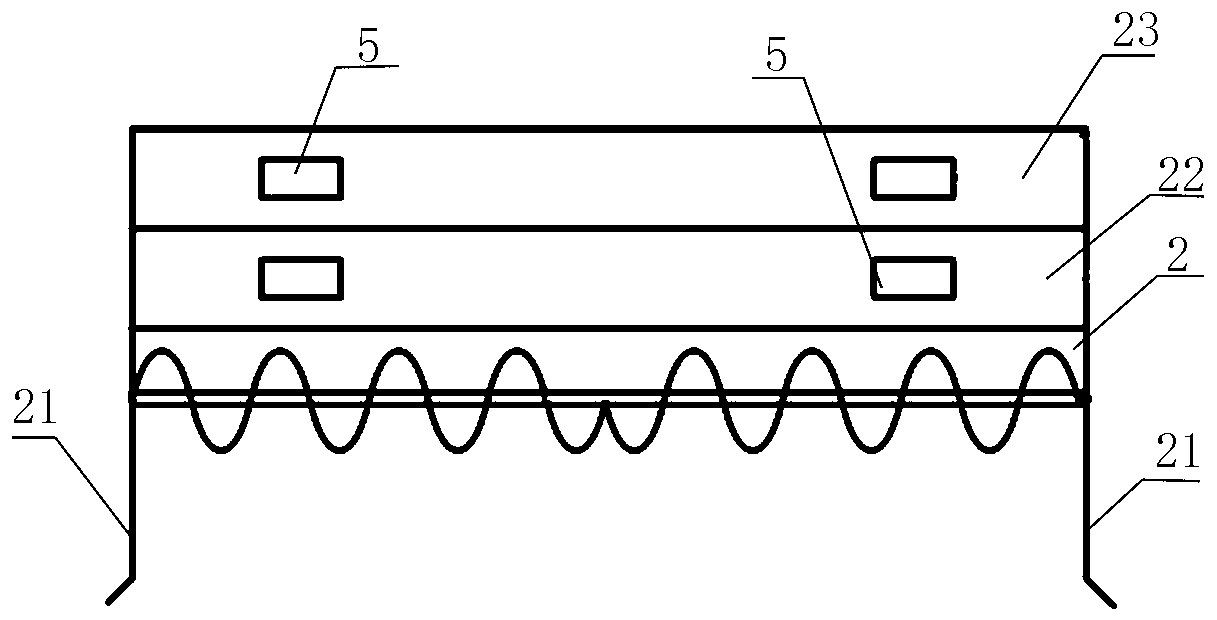

[0023] Such as figure 1 As shown, the structure schematic diagram of the ceramic tile automatic paving equipment of the present invention is given, which consists of a laser level 26 and a screw distributor 2 arranged on the intelligent cart 1, a substrate paving device, and a tile grabbing device 25. It consists of a visual detection device 18, a laser generator 17, and an obstacle avoidance sensor 16. The intelligent pack vehicle 1 is provided with a traveling mechanism 29, which can drive the intelligent pack transport vehicle 1 to walk automatically. Concrete base material is loaded in the smart cart 1, and the ceramic tiles for laying the ground are carried on the top. The obstacle avoidance sensor 16 is fixed on the front end of the smart cart 1, so as to realize the detection of obstacles in the process of advancing. The shown laser generator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com