Machining mold for prefabricated outer wall component

A technology for processing molds and components, applied in the field of processing molds for prefabricated exterior wall components, can solve the problems of increasing construction cost and waste, and the inability of molds to be universal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

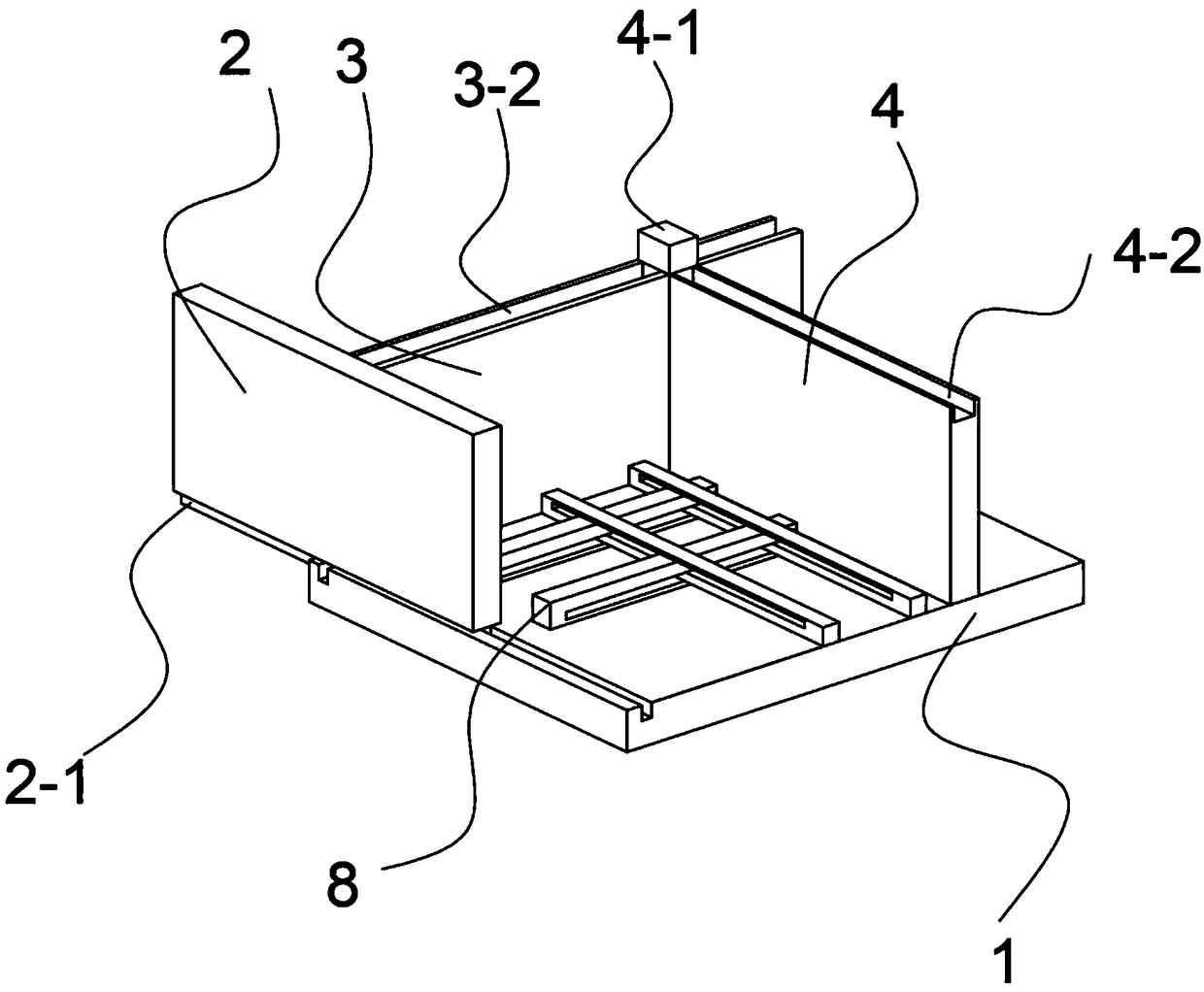

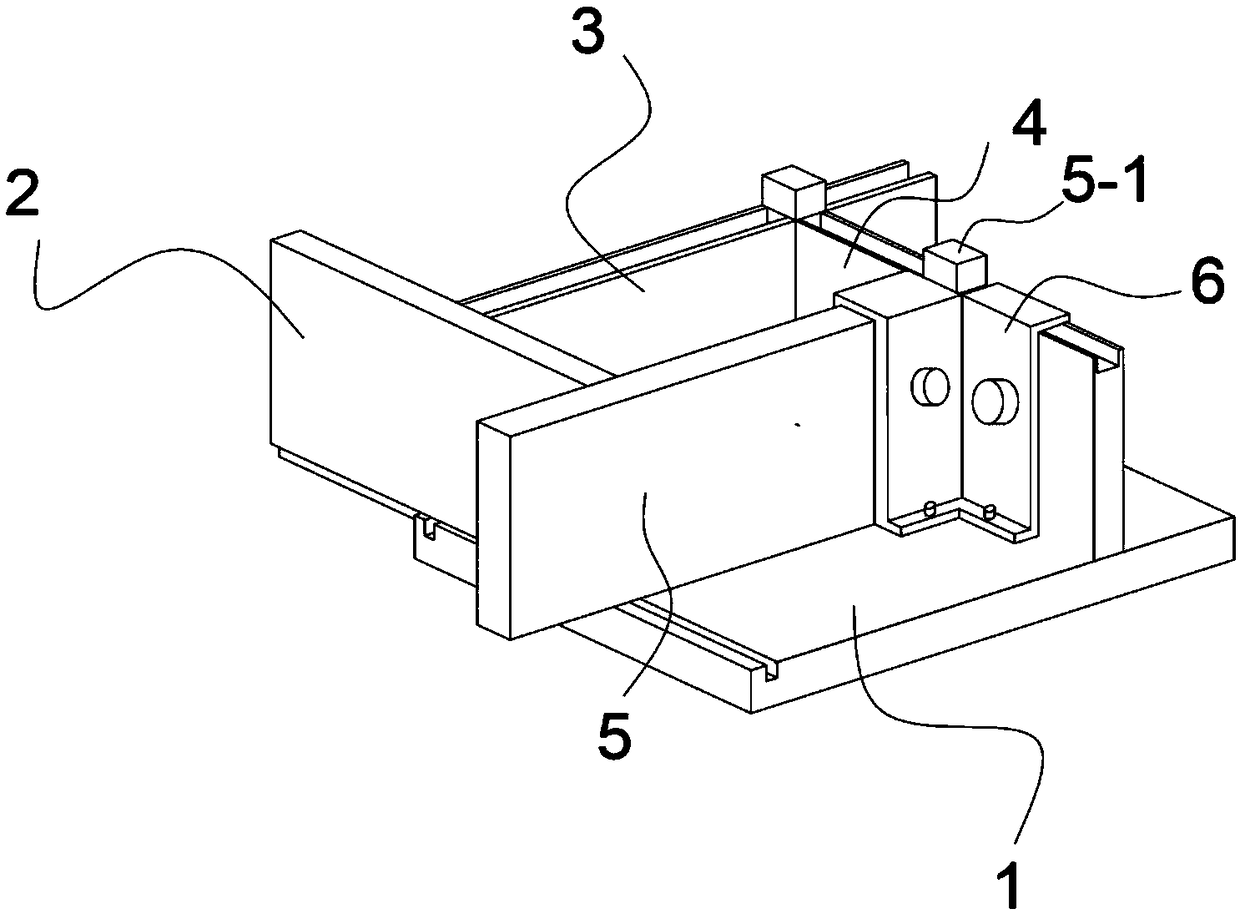

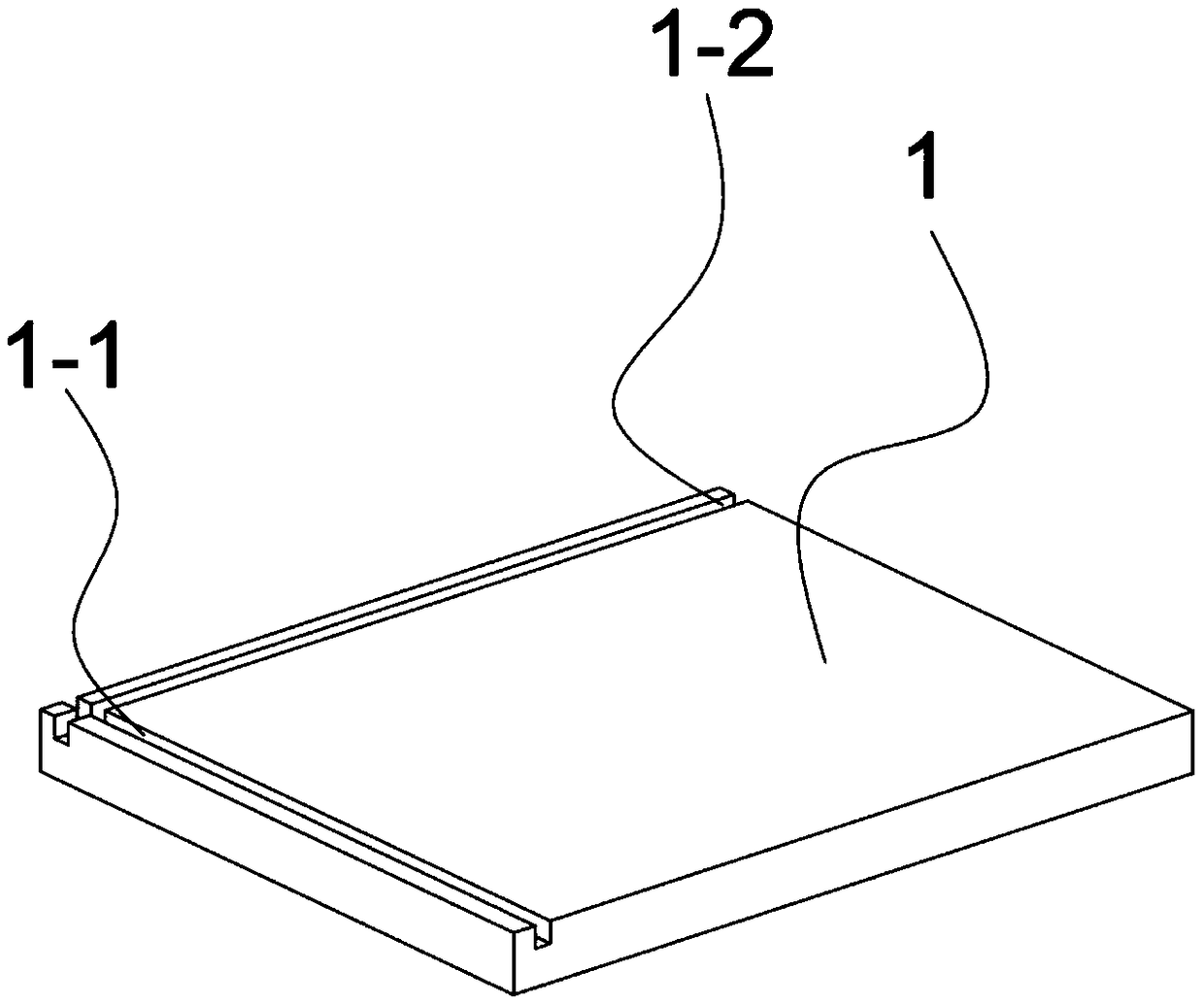

[0033] Such as Figure 1-5 As shown, a processing mold for prefabricating exterior wall components includes a bottom form 1 and a first side form 2, a second side form 3, a third side form 4 and a fourth side form that are slidably arranged on the top of the bottom form 1 5; the top of the bottom mold 1 is provided with a first chute 1-1 along its length direction, and a second chute 1-2 is provided along its width direction; the bottom of the first side mold 2 is provided with the The first slider 2-1 matching the first chute 1-1, the bottom of the second side mold 3 is provided with a second slider 3-1 matching the second chute 1-2 The top of the second side mold 3 is provided with a third chute 3-2, and the third side mold 4 is provided with a third slider 4-1 matching the third chute 3-2 The top of the third side mold 4 is provided with a fourth chute 4-2, and the fourth side mold 5 is provided with a fourth slider 5-1 matching the fourth chute 4-2 ; the first side mold ...

Embodiment 2

[0036] Such as Figure 5 As shown, this embodiment is based on Embodiment 1, the connecting device 6 includes a connecting piece 6-1 and a locking screw 6-2 for fixing the connecting piece 6-1, and the connecting piece 6-1 includes The first connecting part 6-3, the second connecting part 6-4, the third connecting part 6-5, the first buckling part 6-6 and the second buckling part 6-7, the first connecting part 6- One end of 3 is vertically affixed to the second connecting portion 6-4, and the first fastening portion 6-6 is vertically affixed to the other end of the first connecting portion 6-3; the third connecting portion One end of 6-5 is vertically fixed to the second connecting part 6-4, and the side of the third connecting part 6-5 is vertically fixed to the side of the first connecting part 6-3. The other end of the second engaging portion 6-7 is vertically fixed to the third connecting portion 6-5.

[0037] The connecting piece 6-1 is integrally cast, wherein one end ...

Embodiment 3

[0039] Such as Figure 1-5 As shown, this embodiment is based on Embodiment 1, and scales are provided on the tops of the first side form 2 , the second side form 3 , the third side form 4 and the fourth side form 5 . The purpose of setting the ruler is to facilitate more precise adjustment of the size, and at the same time, it is convenient for the user to check whether the size is within a reasonable range and make further adjustments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com