Arc-shaped motion platform for insulator laser cleaning

A technology of arc movement and insulators, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of ensuring focus, improving cleaning efficiency, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

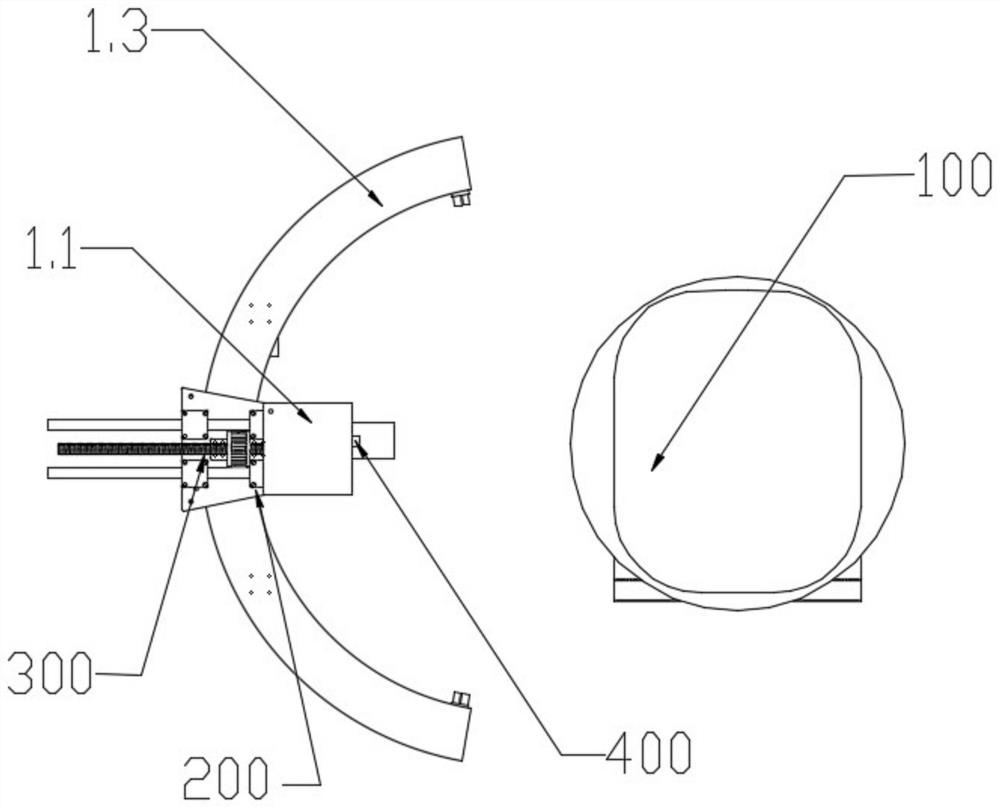

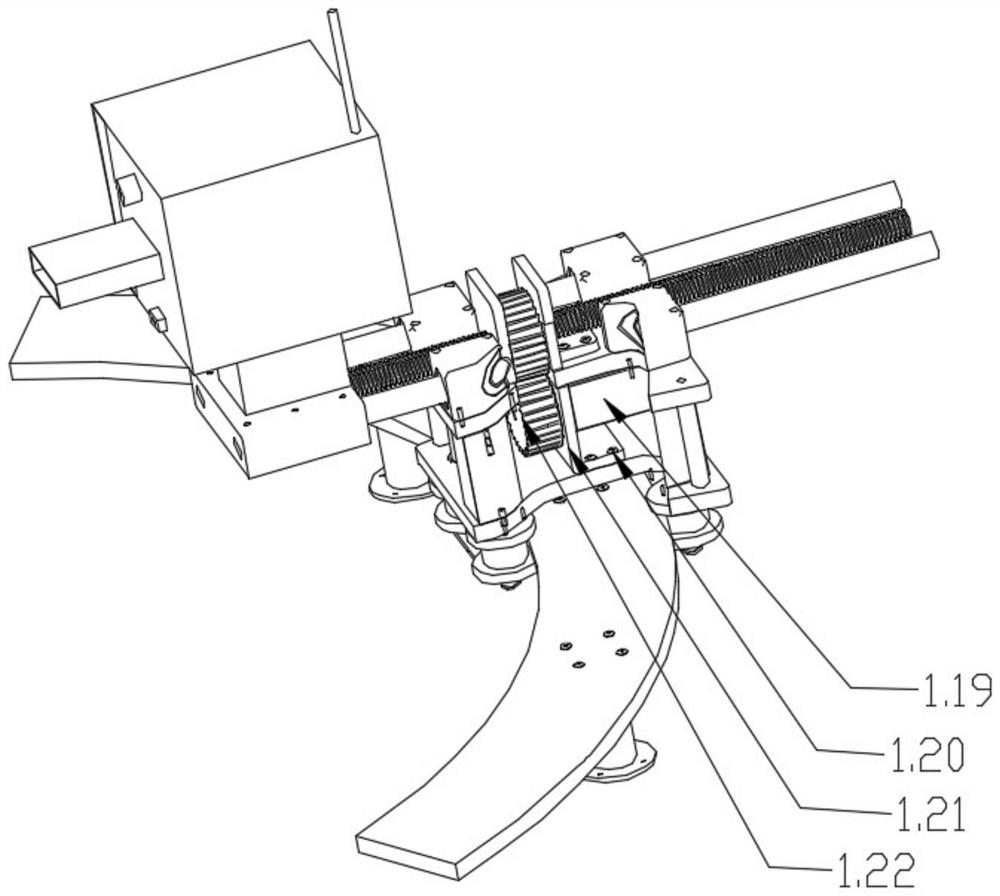

[0056] The above is Embodiment 1 of an arc-shaped motion platform for laser cleaning of insulators provided by the embodiment of the present application. The following is Embodiment 2 of an arc-shaped motion platform for laser cleaning of insulators provided by the embodiment of the application. For details, please refer to Figure 1 to Figure 4 .

[0057] Based on the technical solution of the first embodiment above:

[0058] Further, in terms of the structural composition of the first moving device 200, it may include a sliding seat 1.9 and a friction wheel 1.24 mechanism. The sliding seat 1.9 slides with the arc track 1.3 through the friction wheel 1.24 mechanism; the friction wheel 1.24 mechanism is installed on the sliding seat 1.9.

[0059] Specifically, the friction wheel 1.24 mechanism may include a plurality of friction wheel sets and a first drive motor 1.10. A plurality of friction wheel sets are pivotally fixed to the bottom of the sliding seat 1.9, and are distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com