Patents

Literature

76results about How to "Easy to cut to length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

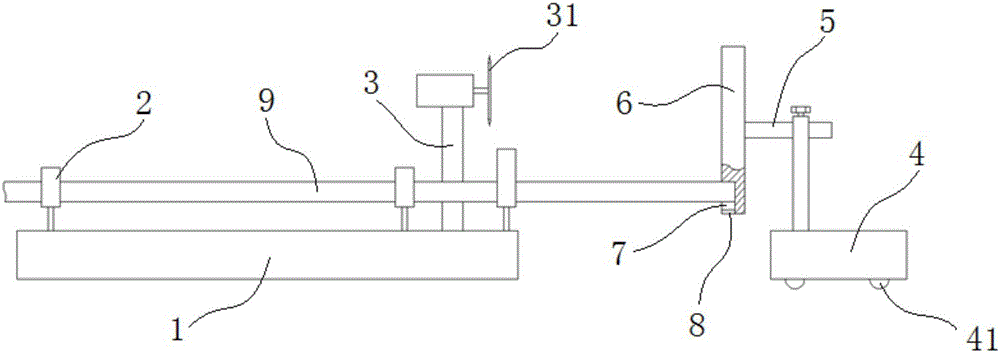

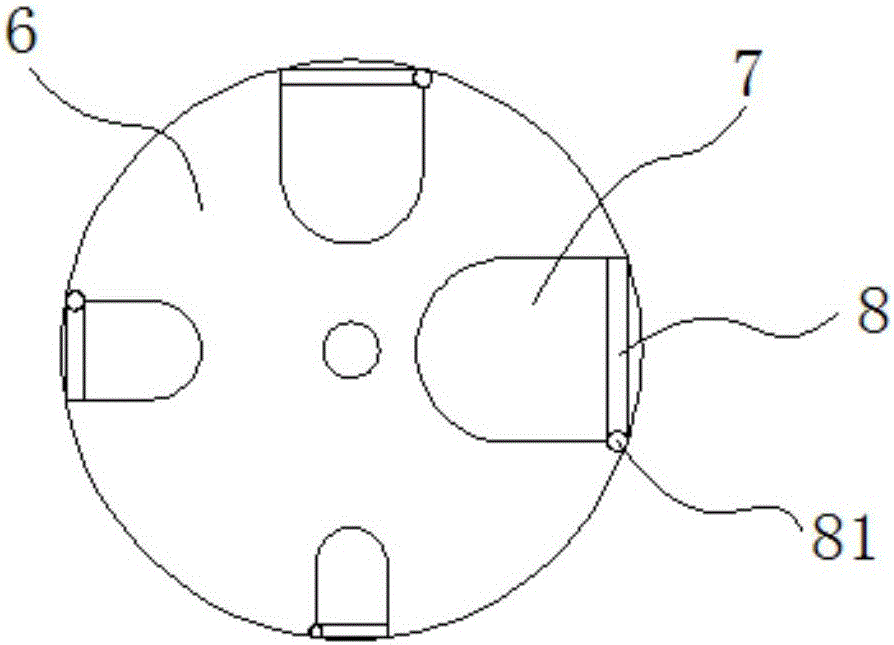

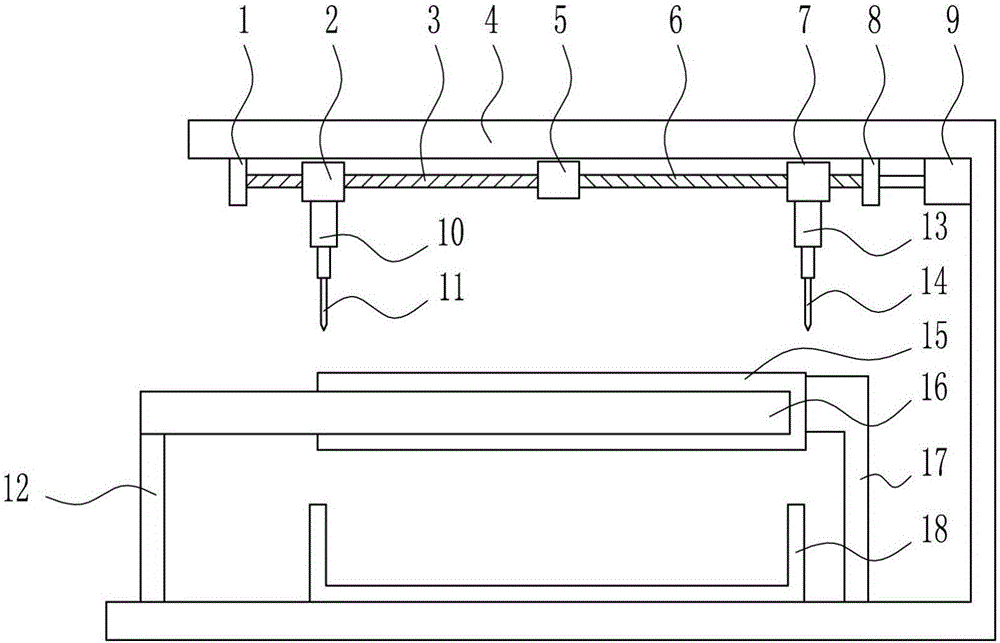

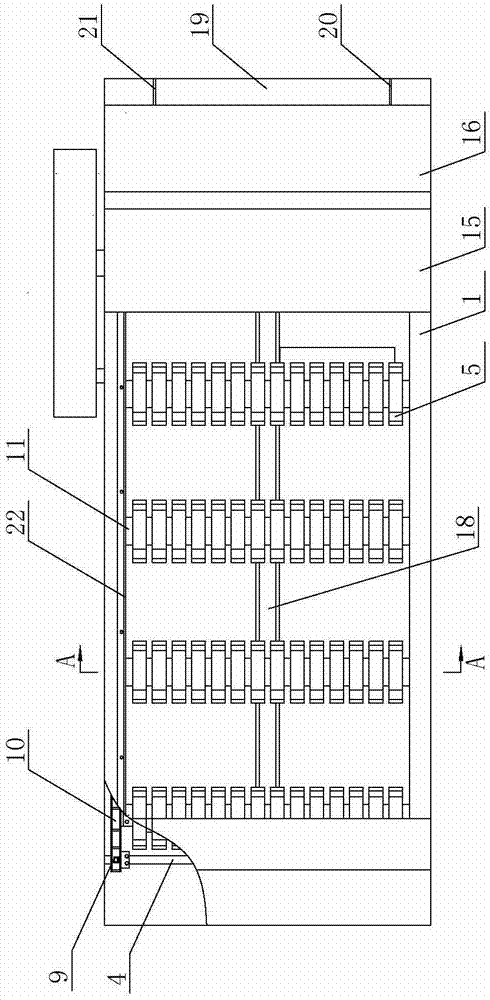

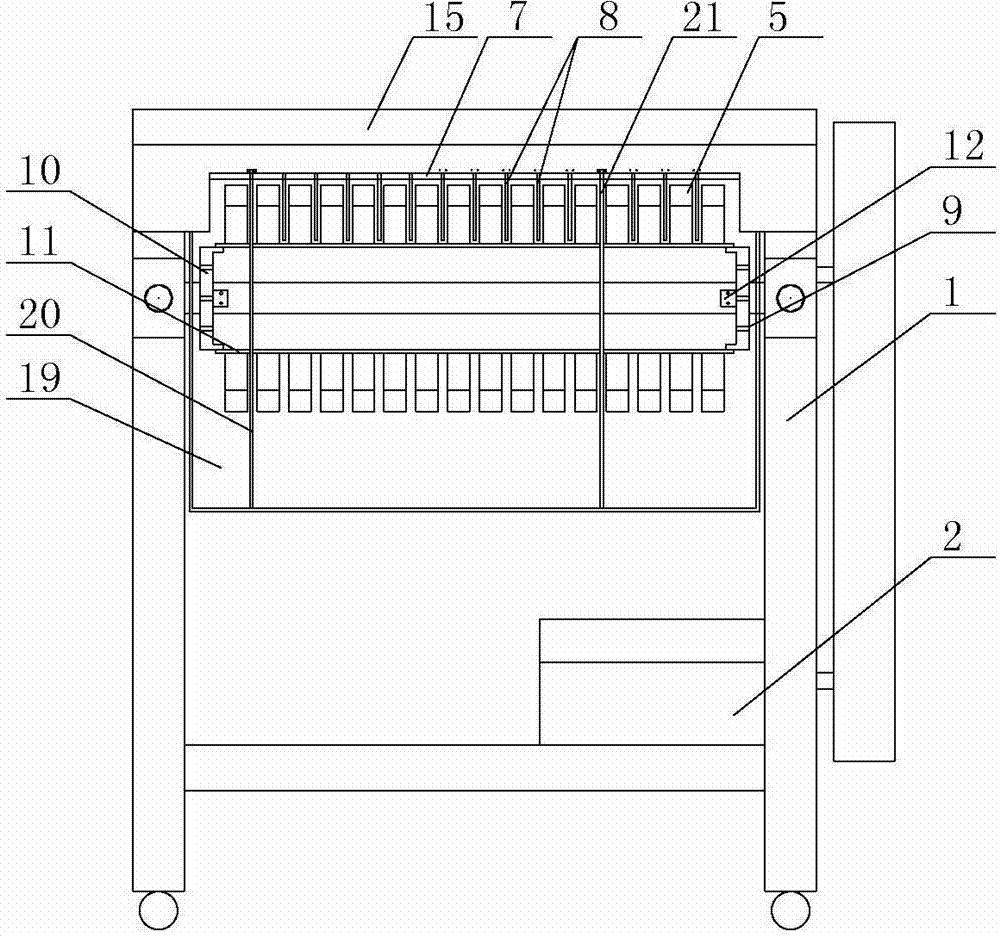

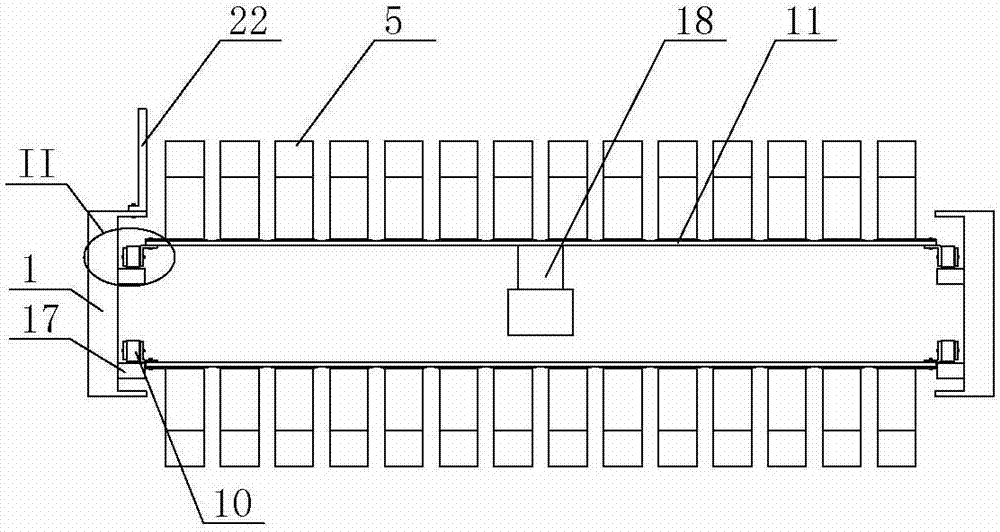

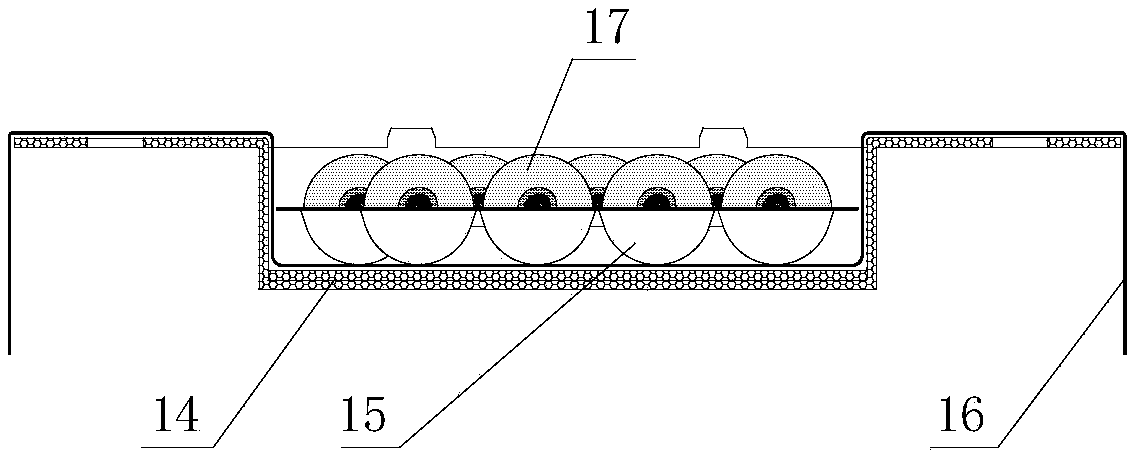

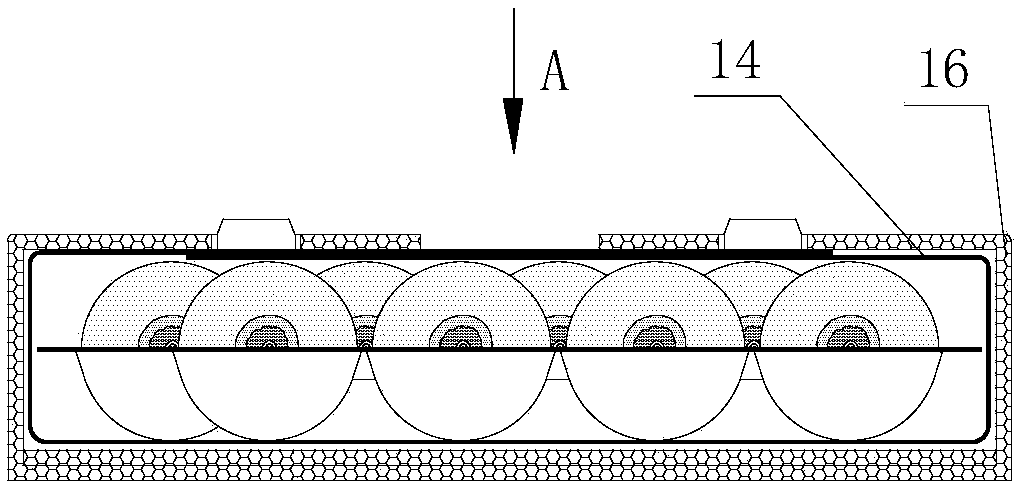

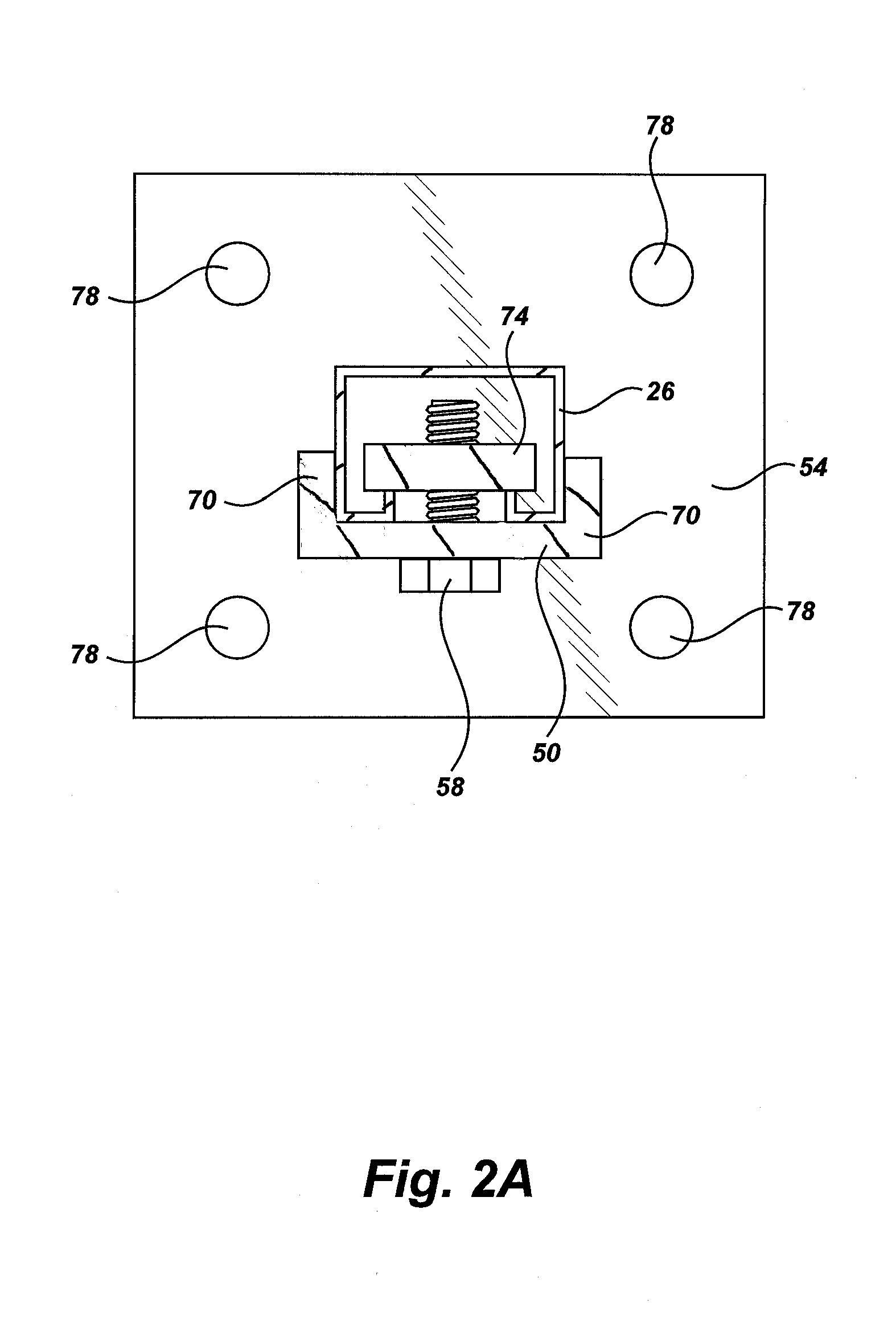

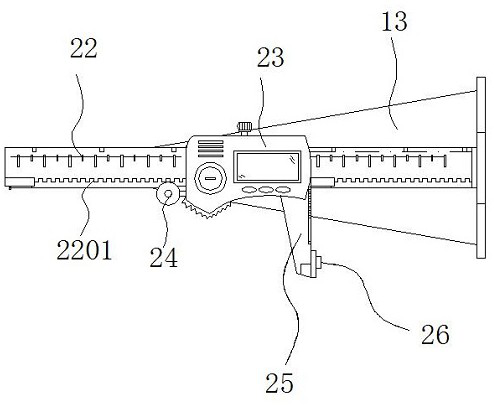

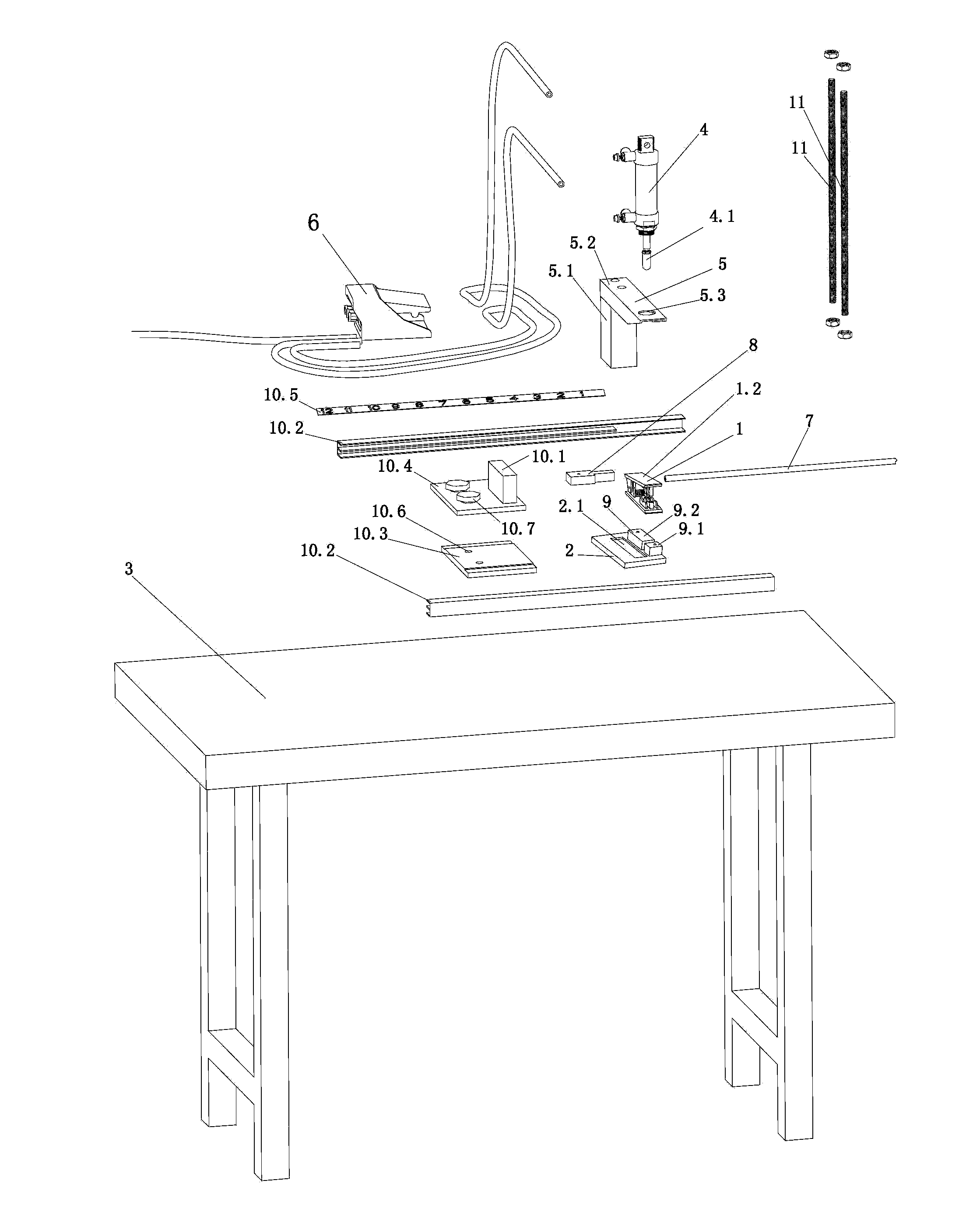

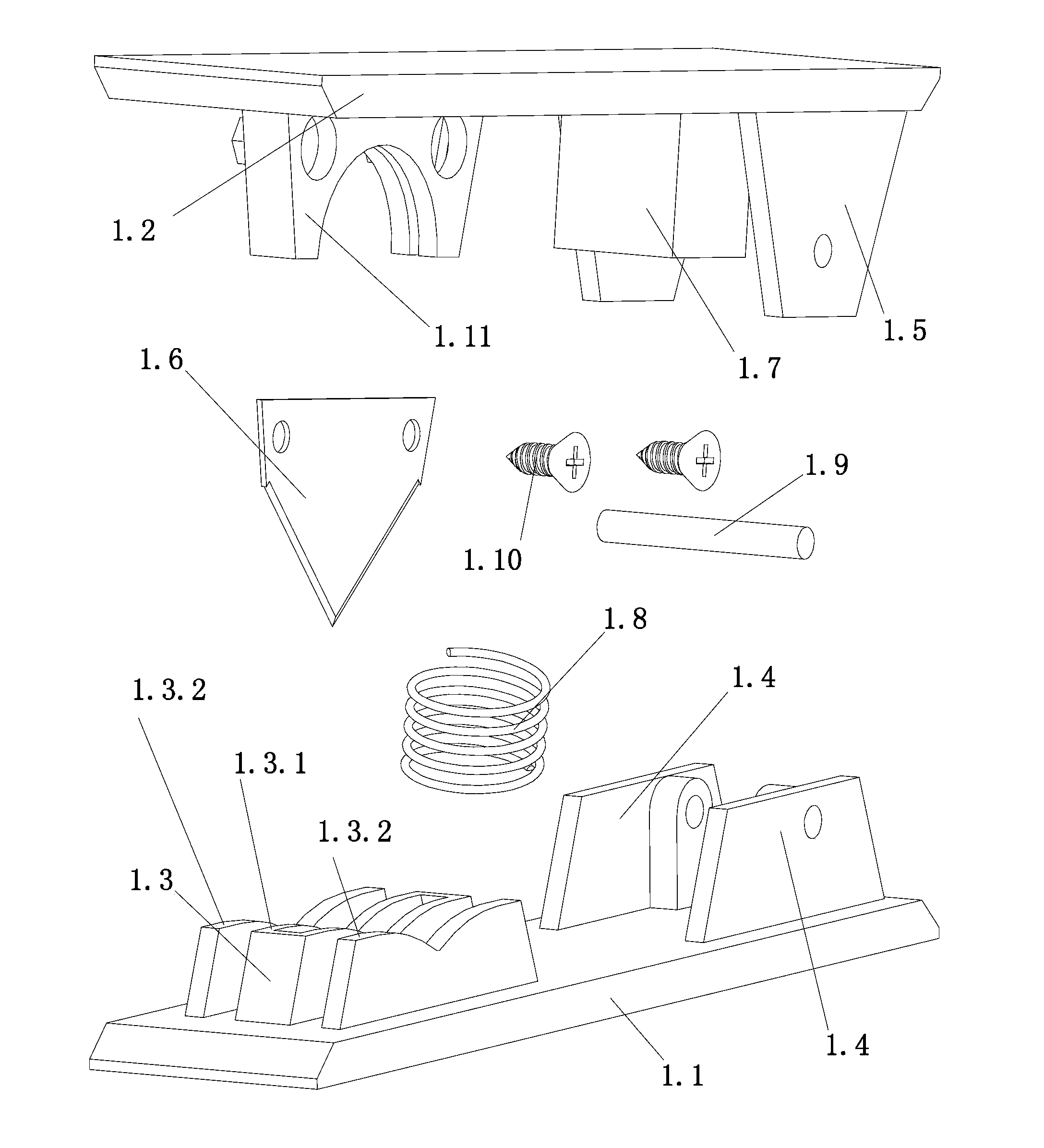

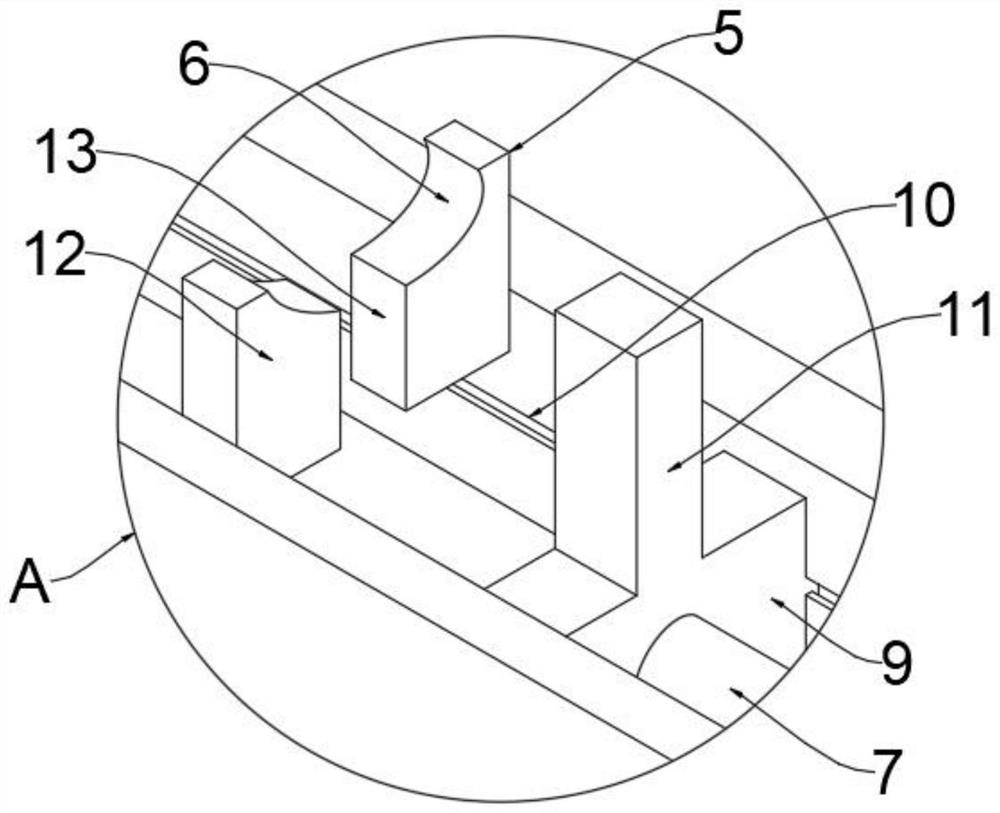

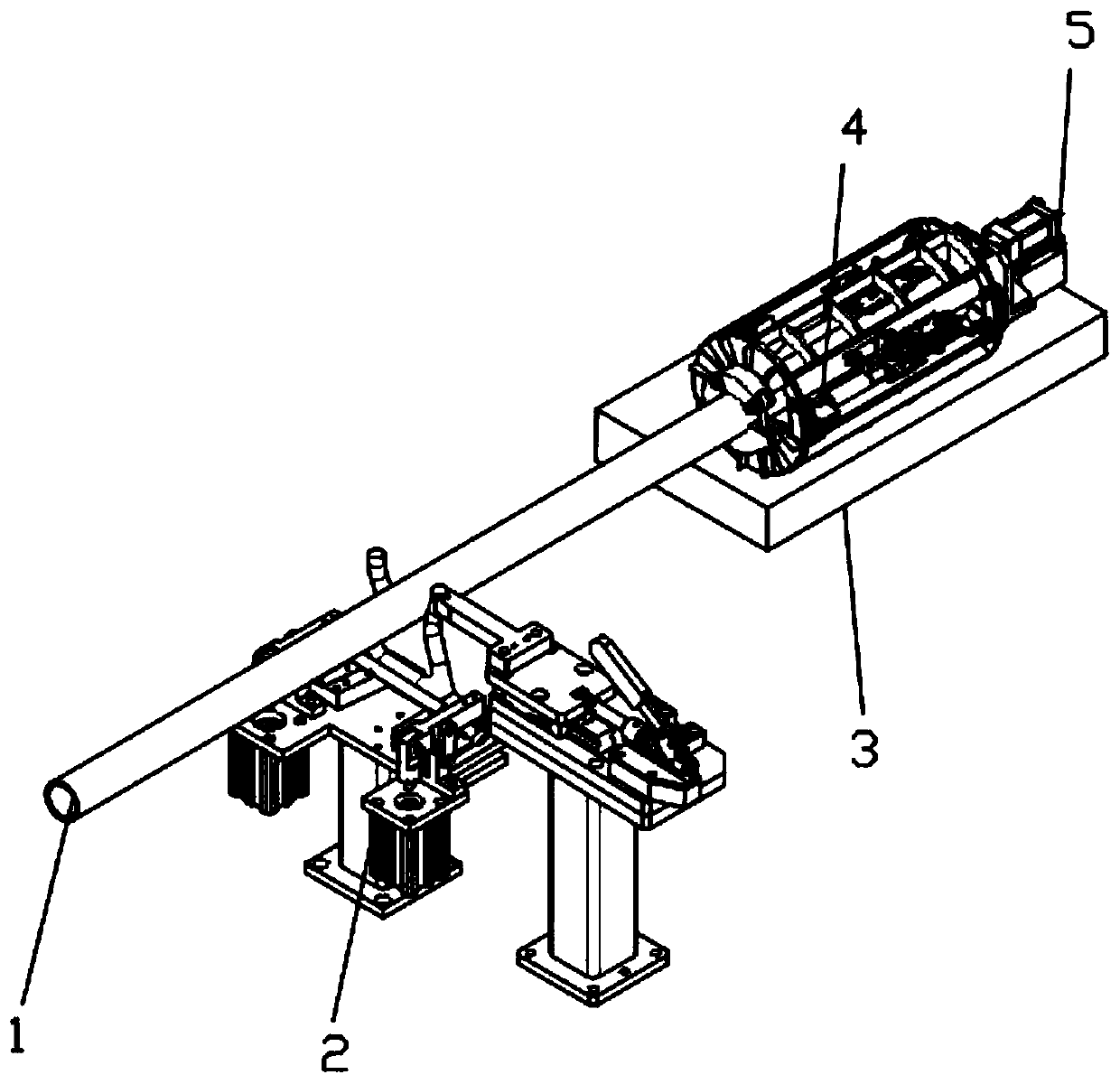

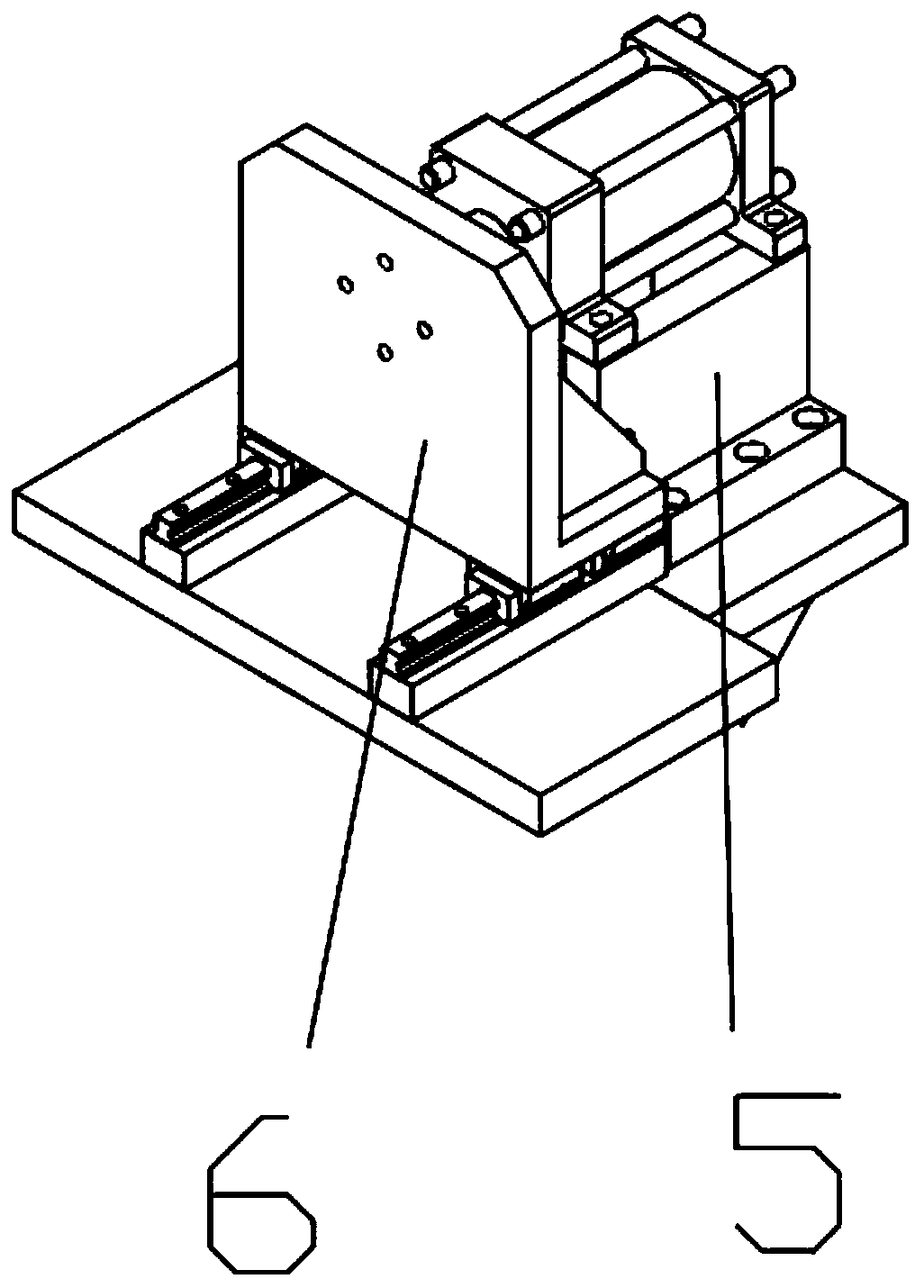

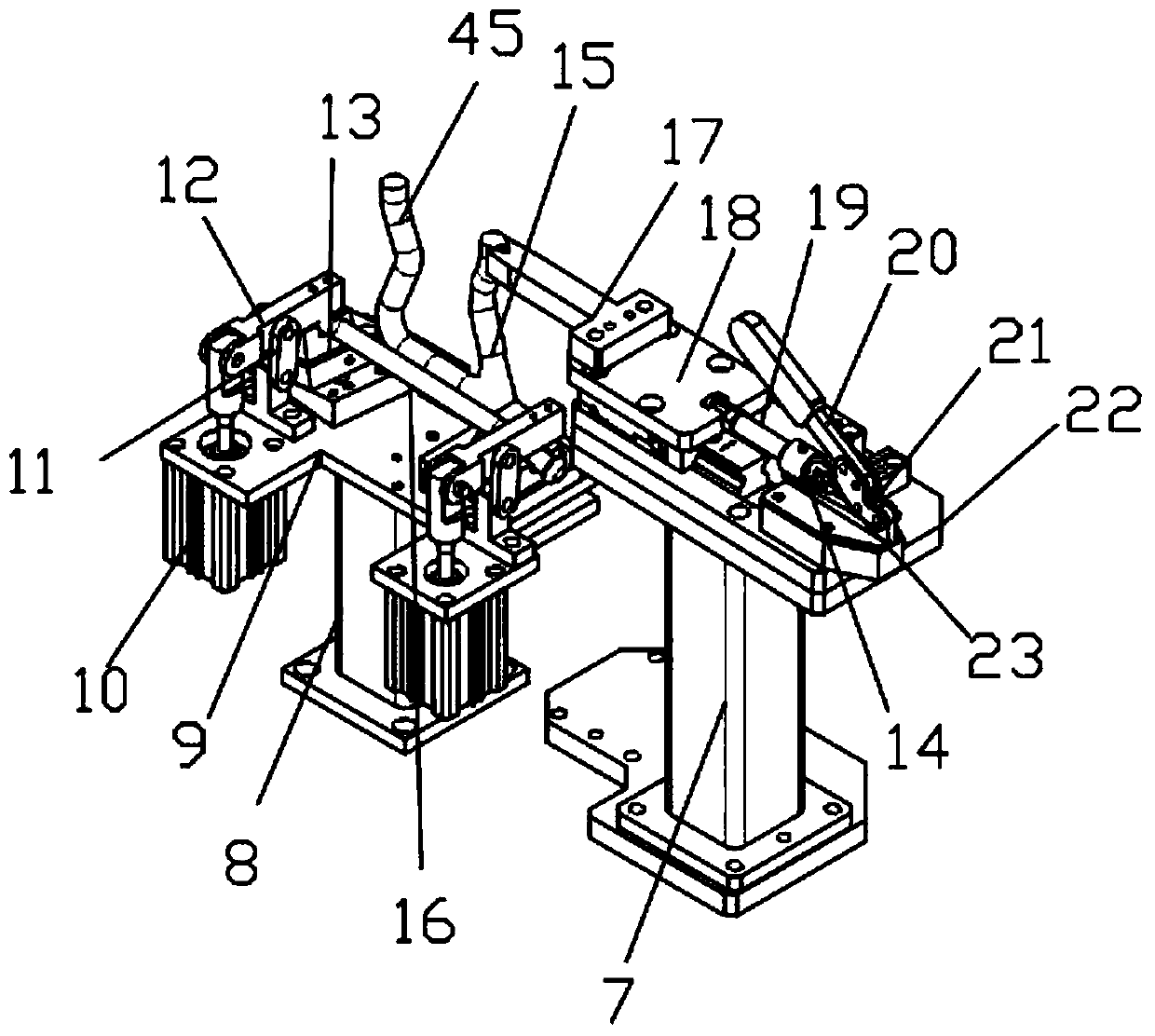

Fixed-length cutting device for tubes

ActiveCN105689788AEasy to cut to lengthImprove securityTube shearing machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a fixed-length cutting device for tubes. The fixed-length cutting device comprises a cutting table, a cutting device, support elements, a location table, a support shaft, a location disc and baffles, wherein the cutting device is arranged at the front end of the cutting table; the plurality of support elements are arranged on the cutting table along the same straight line, wherein the support element at the forefront is located in front of the cutting device; the location table is arranged in front of the cutting table; the support shaft is erected on the location table in a manner of being capable of sliding forwards and backwards; the location disc is rotatably arranged at the rear end of the support shaft in a sleeving manner, a plurality of U-shaped grooves are arranged in the rear end surface of the location disc in a sinking manner along a peripheral direction, and the opening of each U-shaped groove penetrates through the sidewall of the location disc; one baffle is arranged at the opening of each U-shaped groove in a covering manner; and one end of each baffle is hinged at one side of the opening of the corresponding U-shaped groove through a pin shaft, and a torsional spring is arranged on each pin shaft in a sleeving manner. The fixed-length cutting device disclosed by the invention is capable of conveniently carrying out fixed-length cutting on the tubes, safe and efficient in cutting process, and low in cost.

Owner:海宁经开产业园区开发建设有限公司

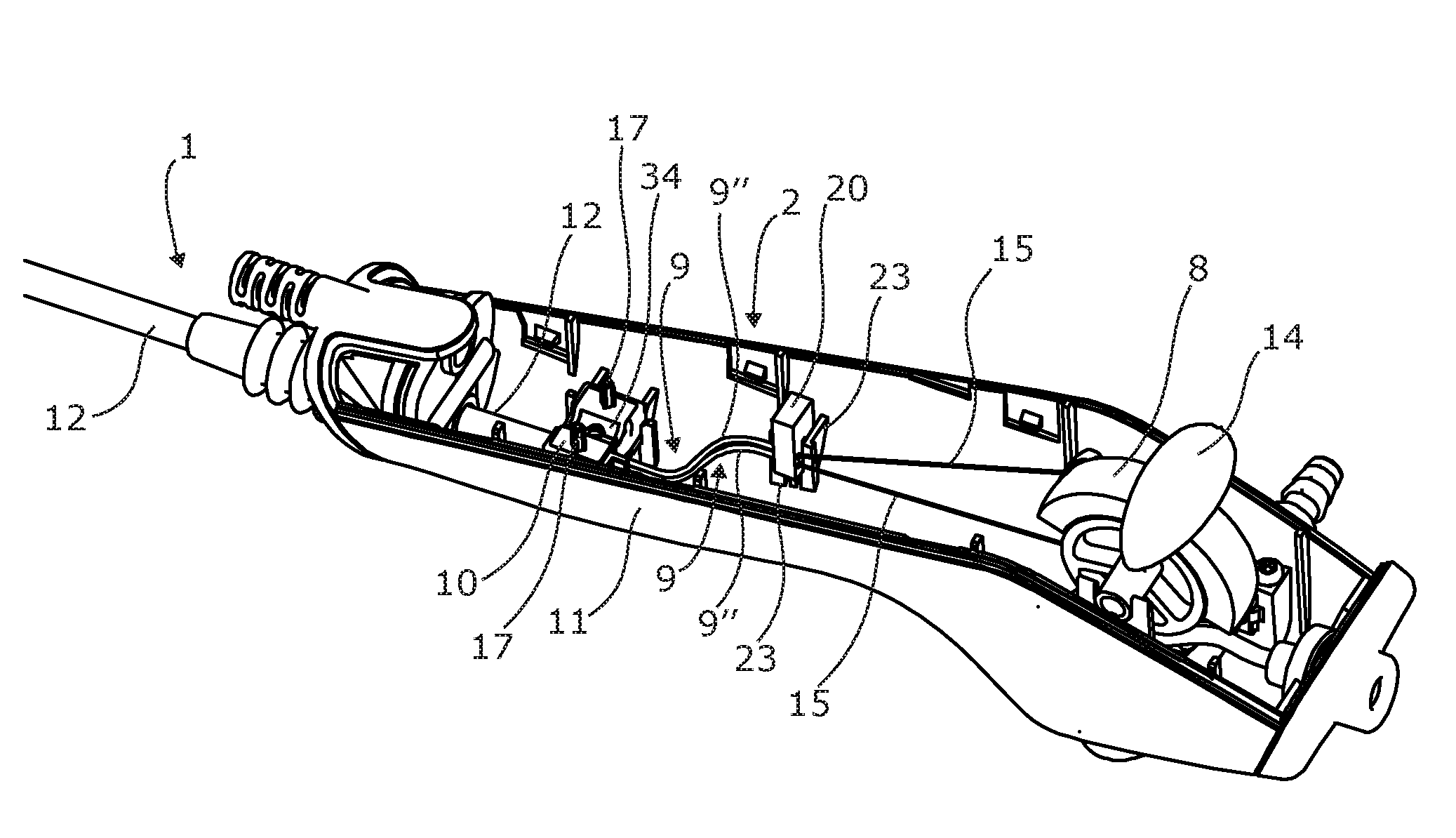

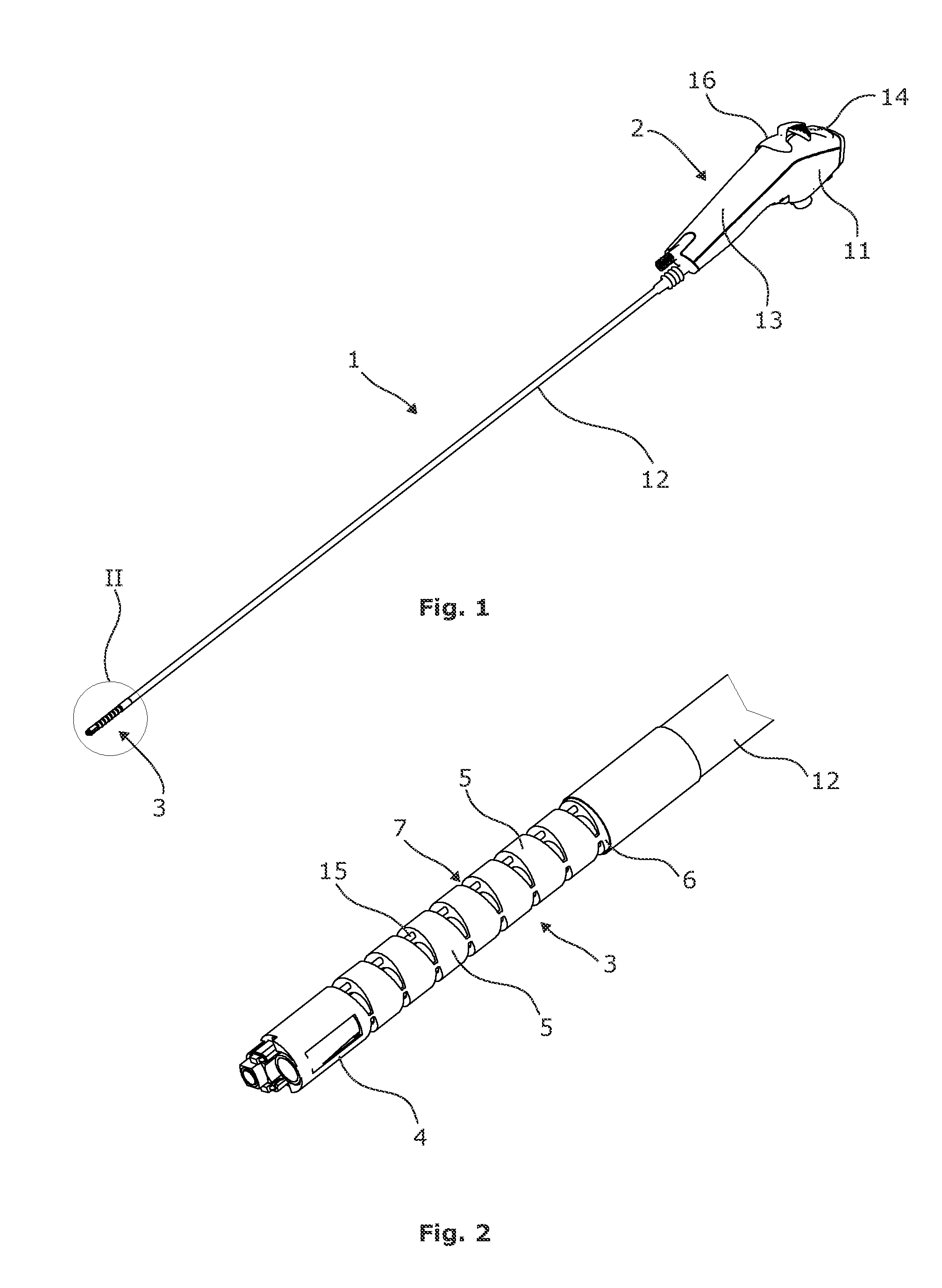

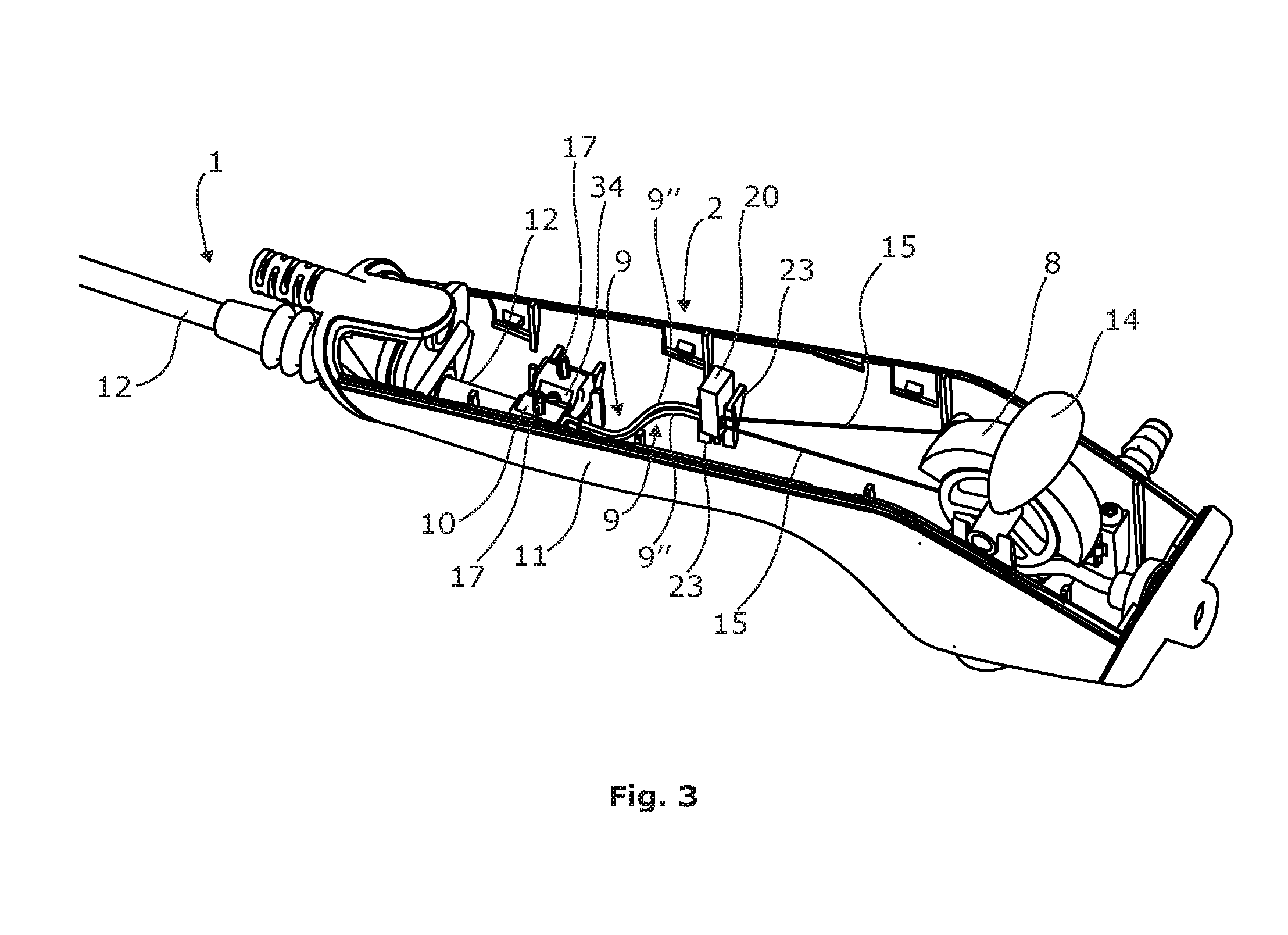

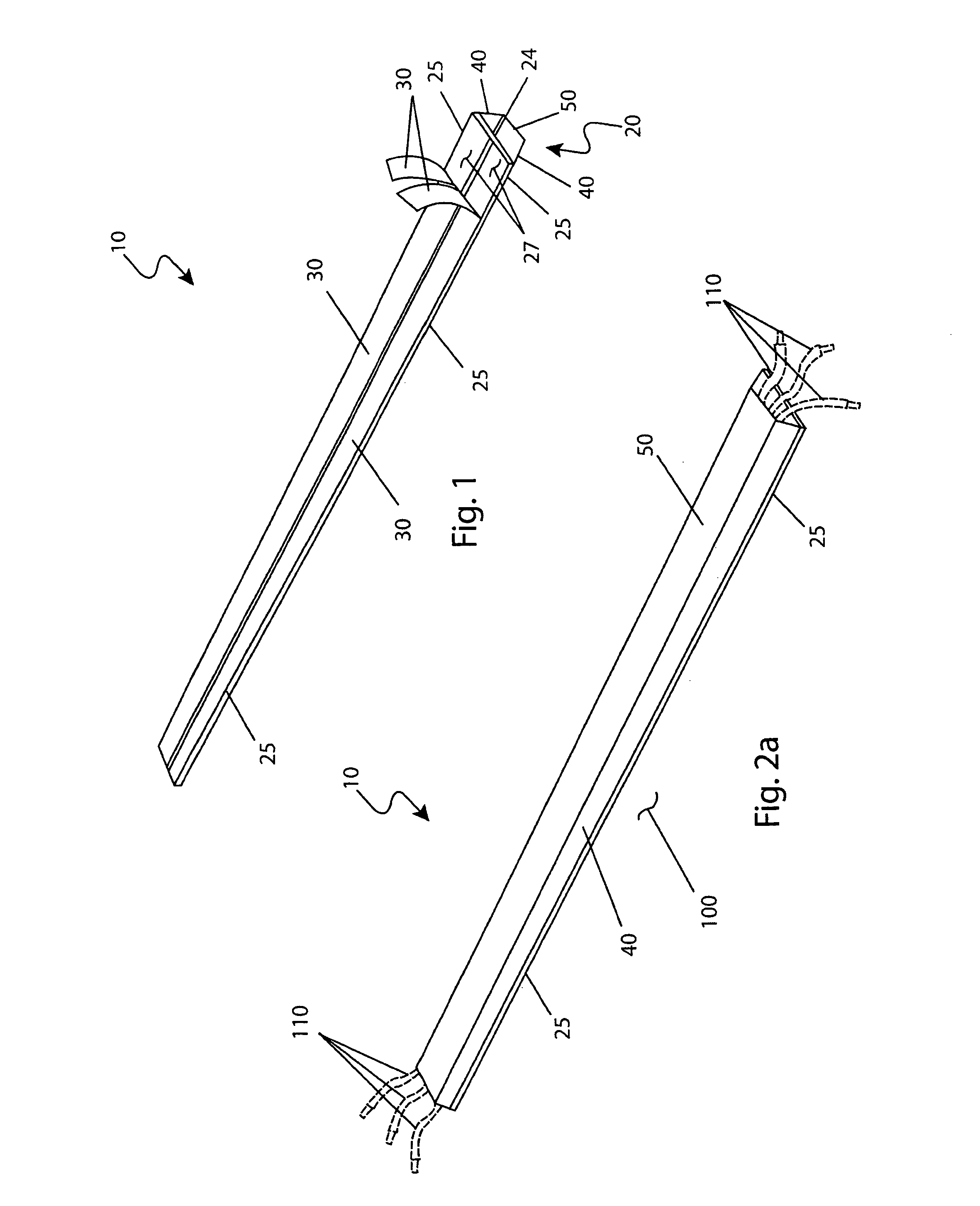

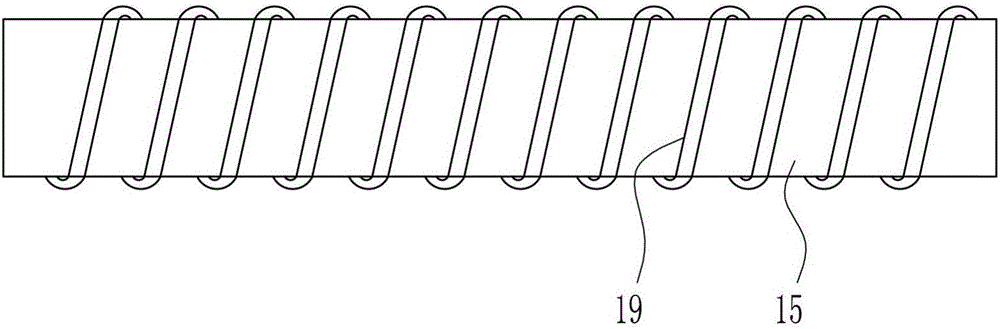

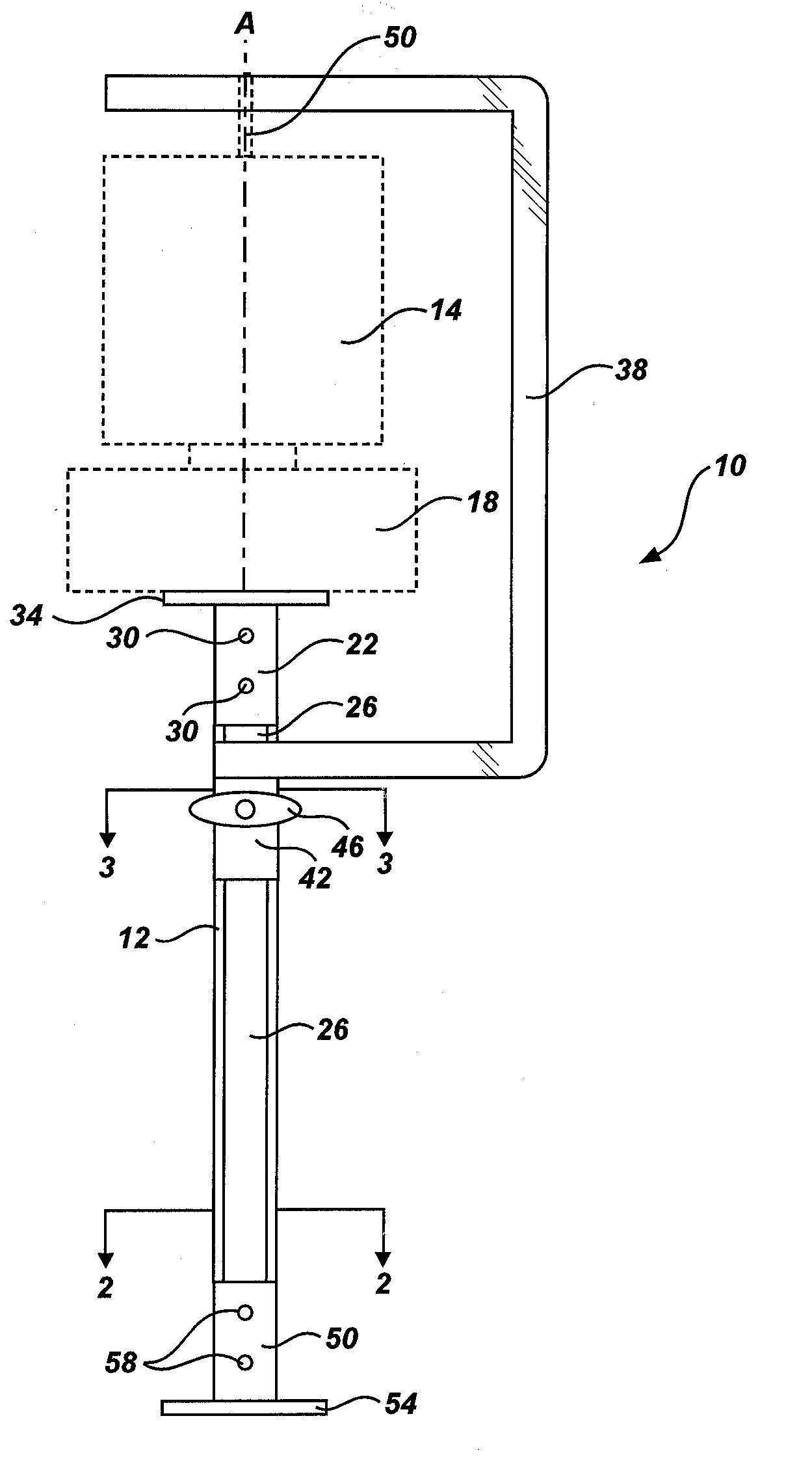

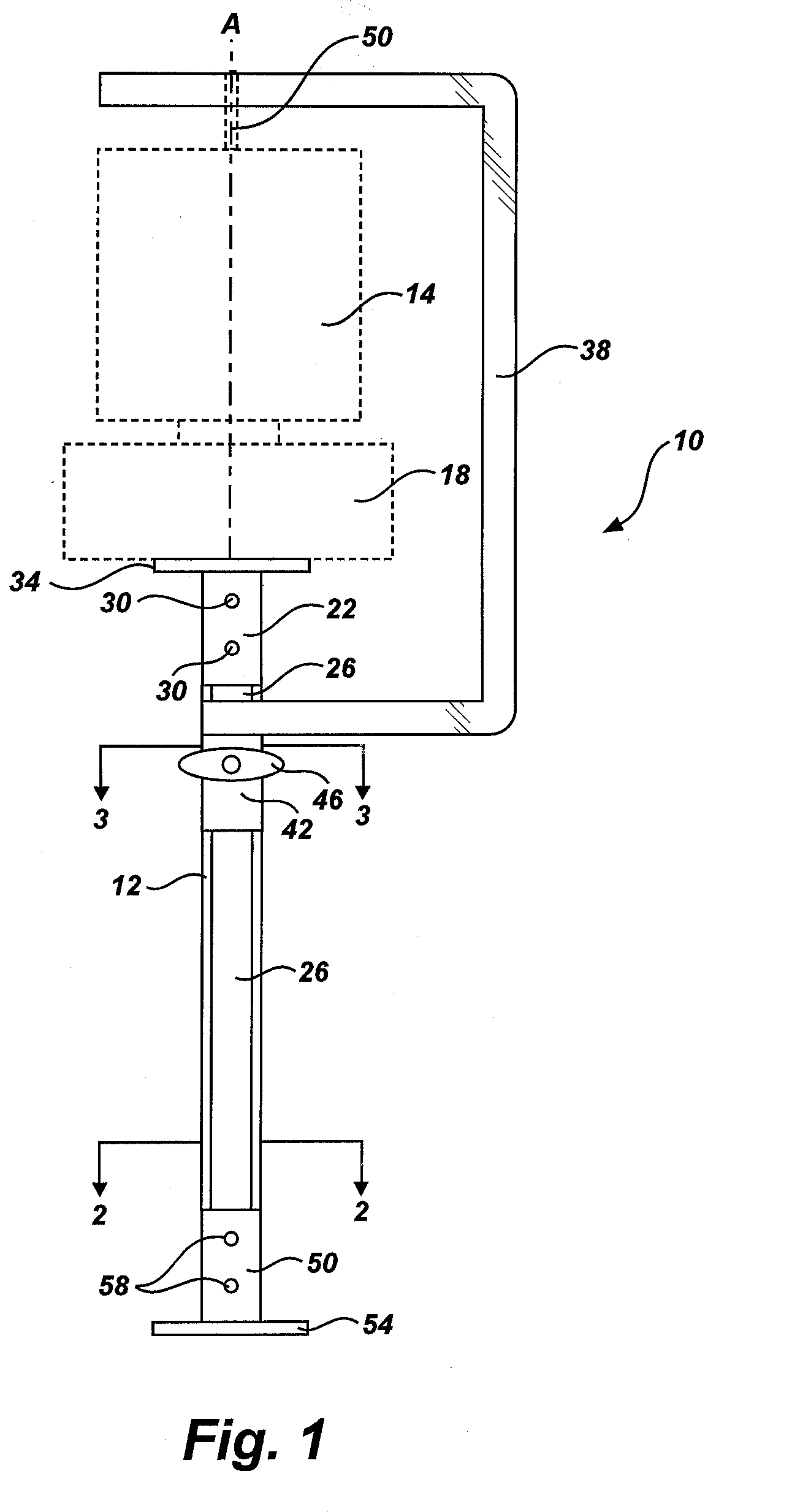

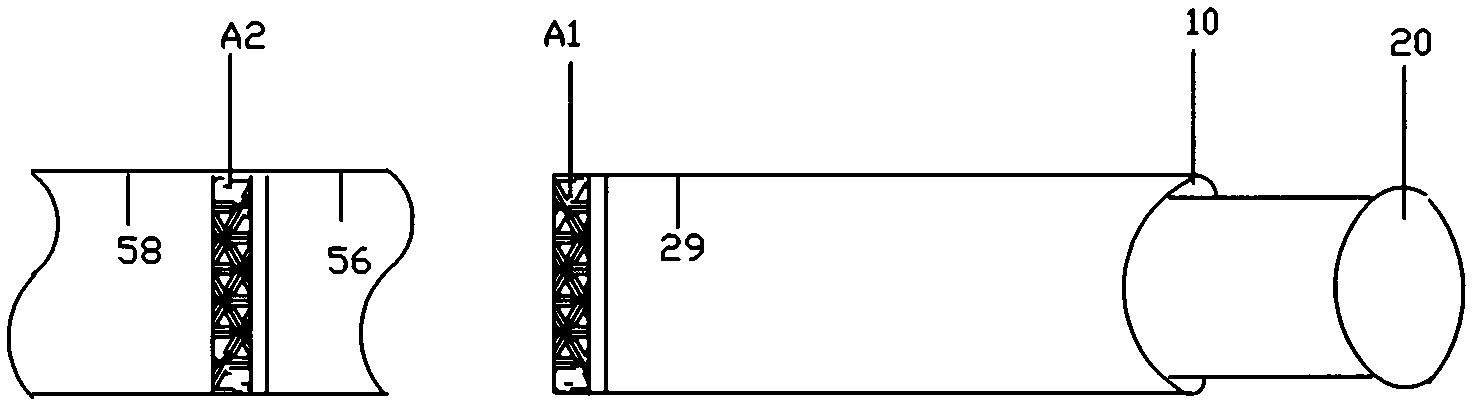

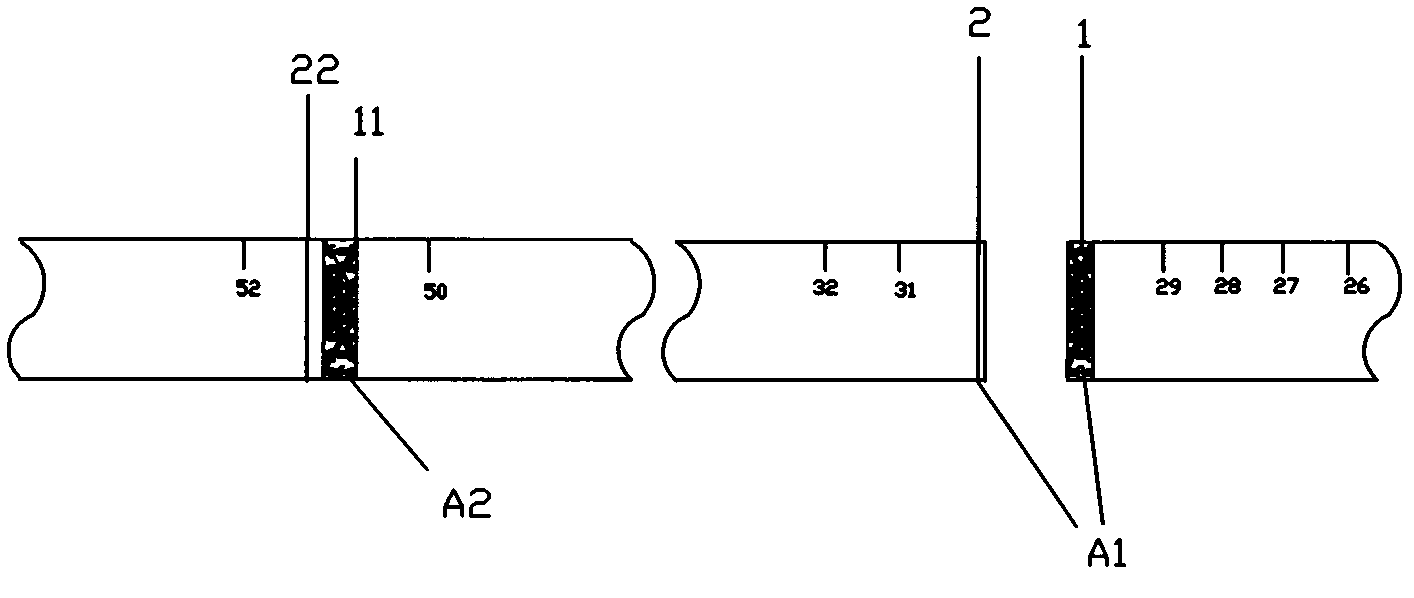

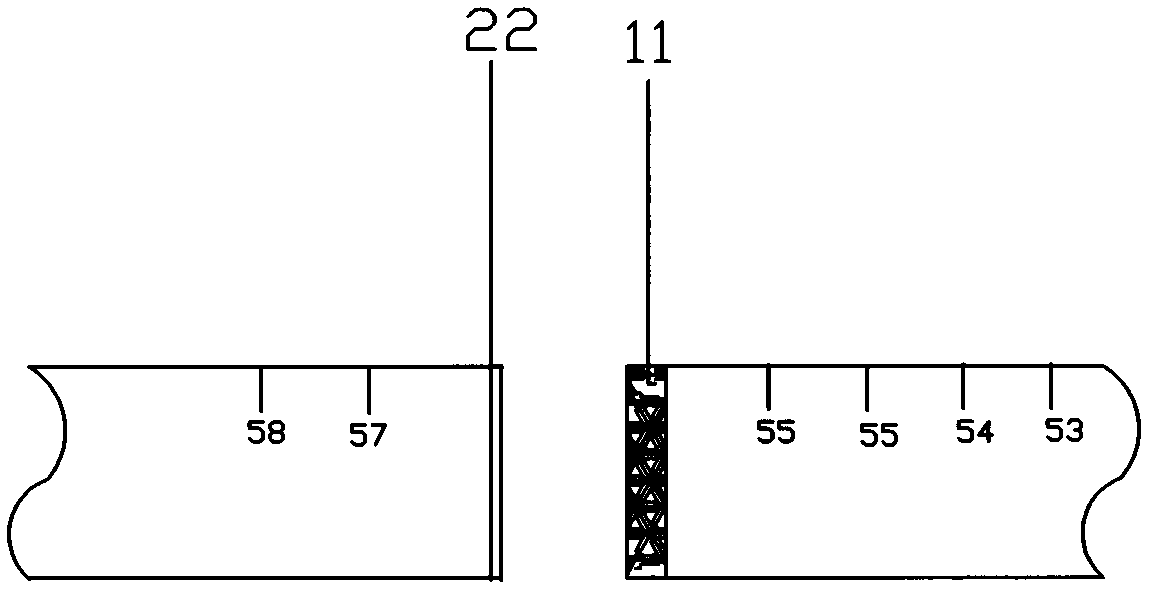

Apparatus for maintaining a tensioned pull-wire in an endoscope

ActiveUS20150366436A1Less complicated to manufactureIncrease flexibilitySurgeryEndoscopesBowden cableEngineering

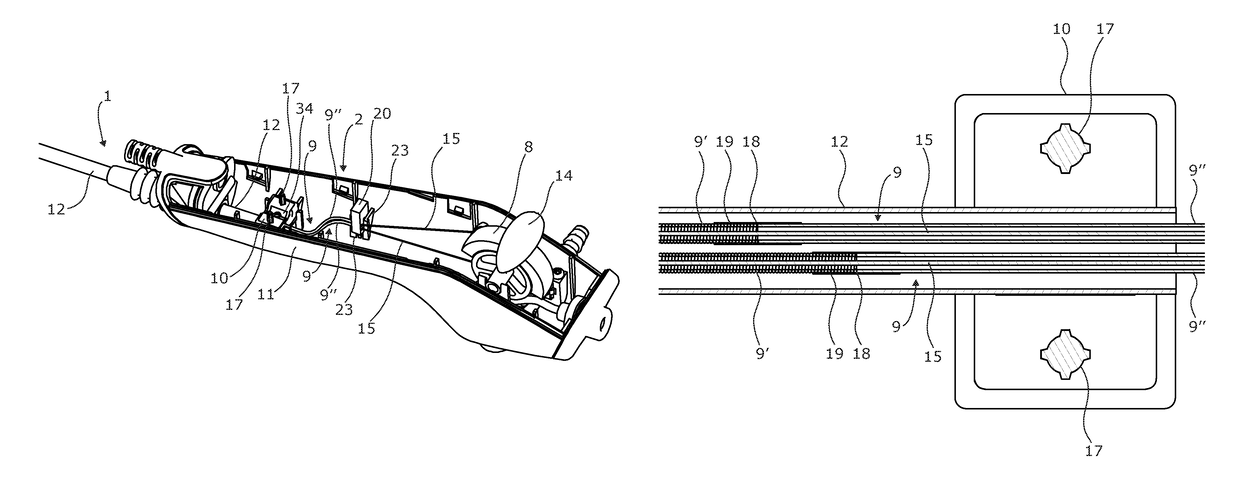

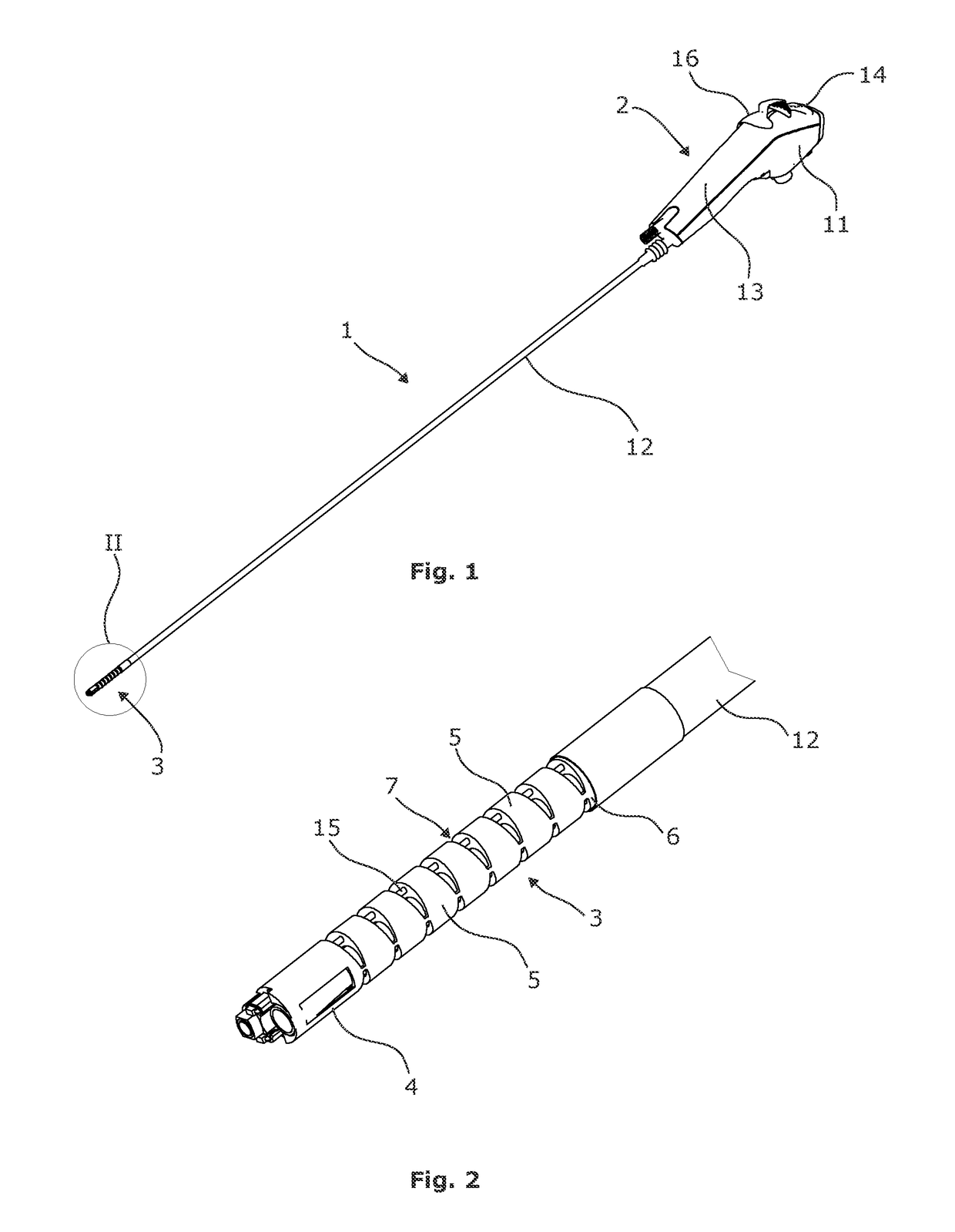

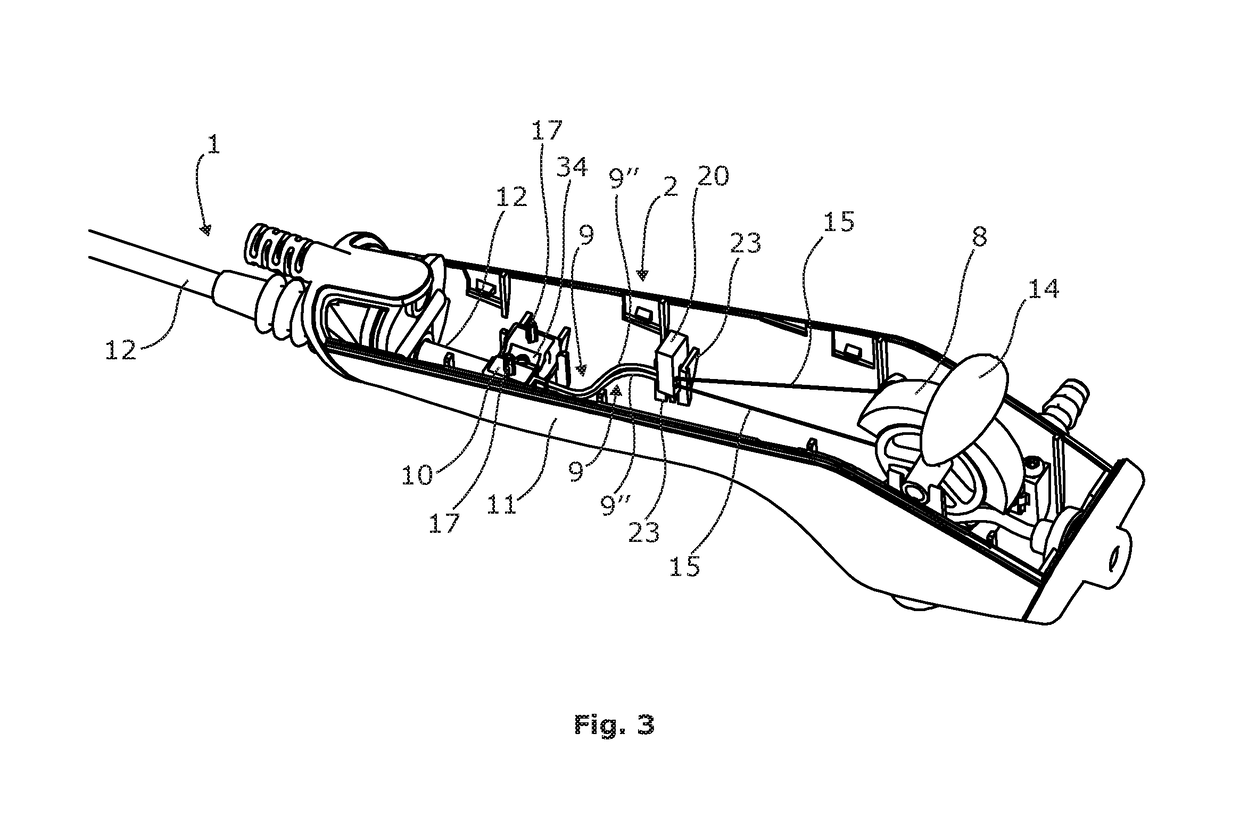

A control mechanism for an endoscope (1) comprising a Bowden cable, the Bowden cable has an outer guide tube (9) having a first length between a proximal end and a distal end of said outer guide tube (9) and an inner pull-wire (15) having a second length between a proximal end and a distal end of said inner pull-wire (15). The second length is longer than the first length. The outer guide tube (9) comprises a first guide tube section (9′) and a second guide tube section, where said first guide tube section (9′) has plastic and elastic properties, which are different from the plastic and elastic properties of said second guide tube section (9″).

Owner:AMBU AS

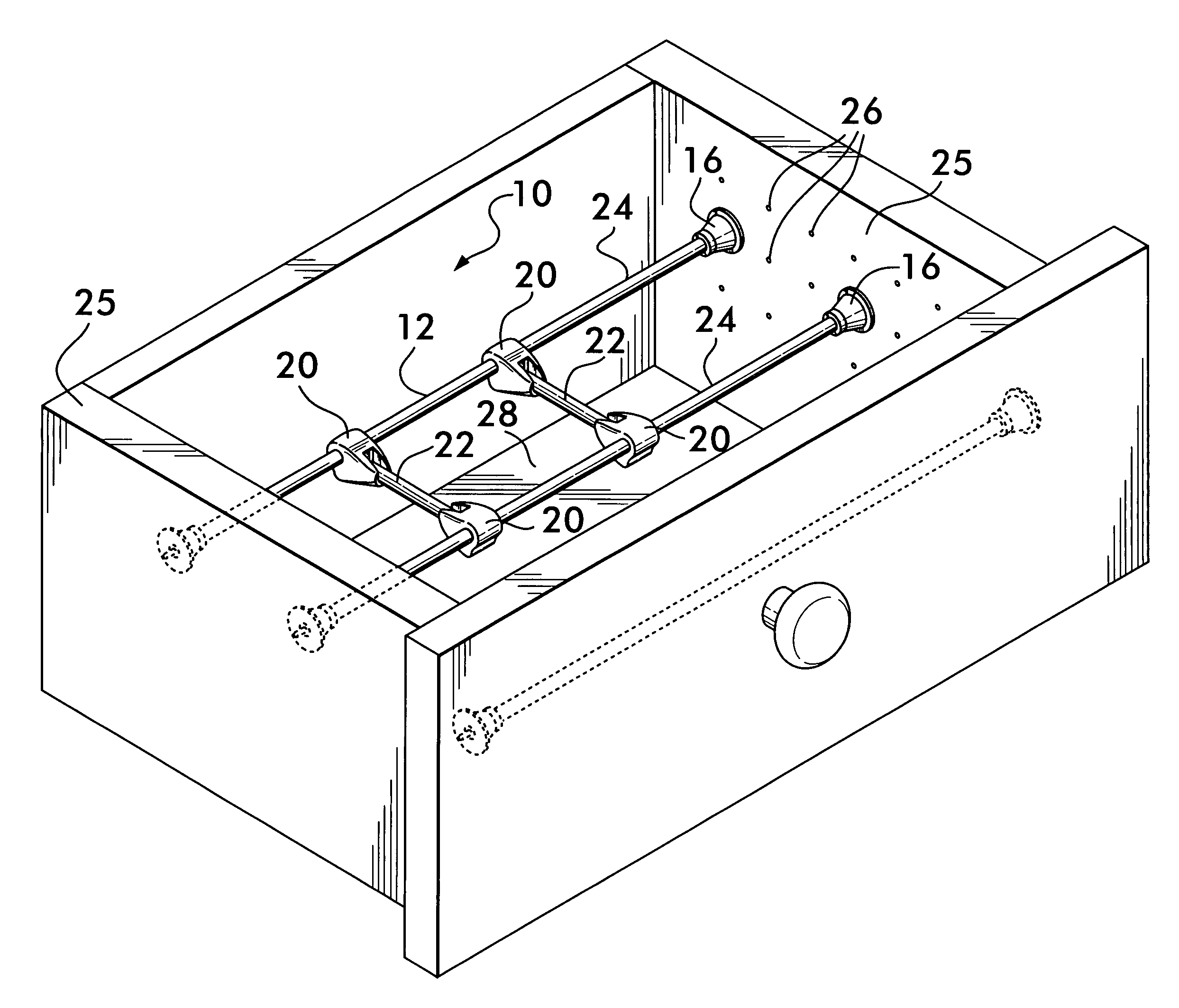

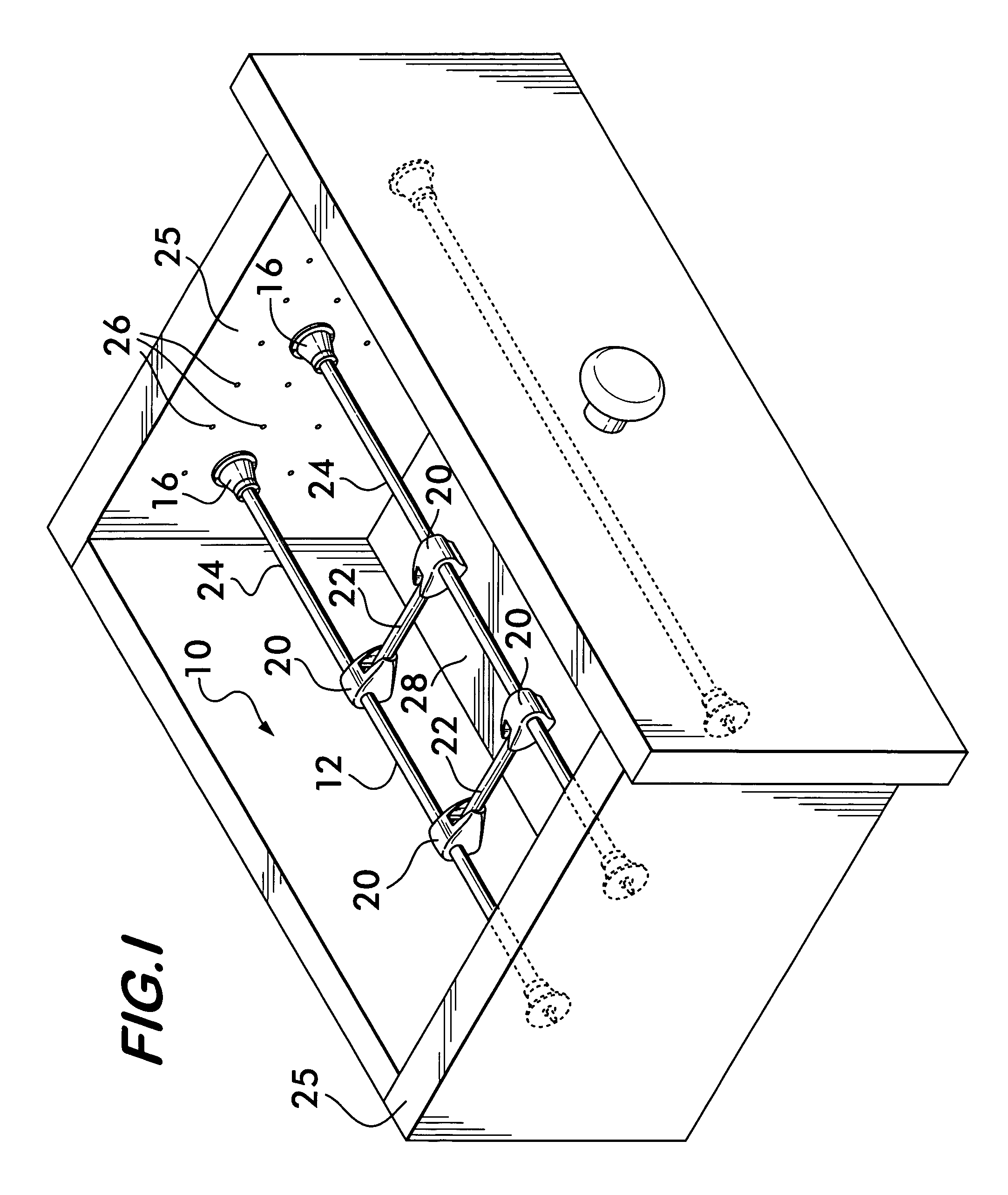

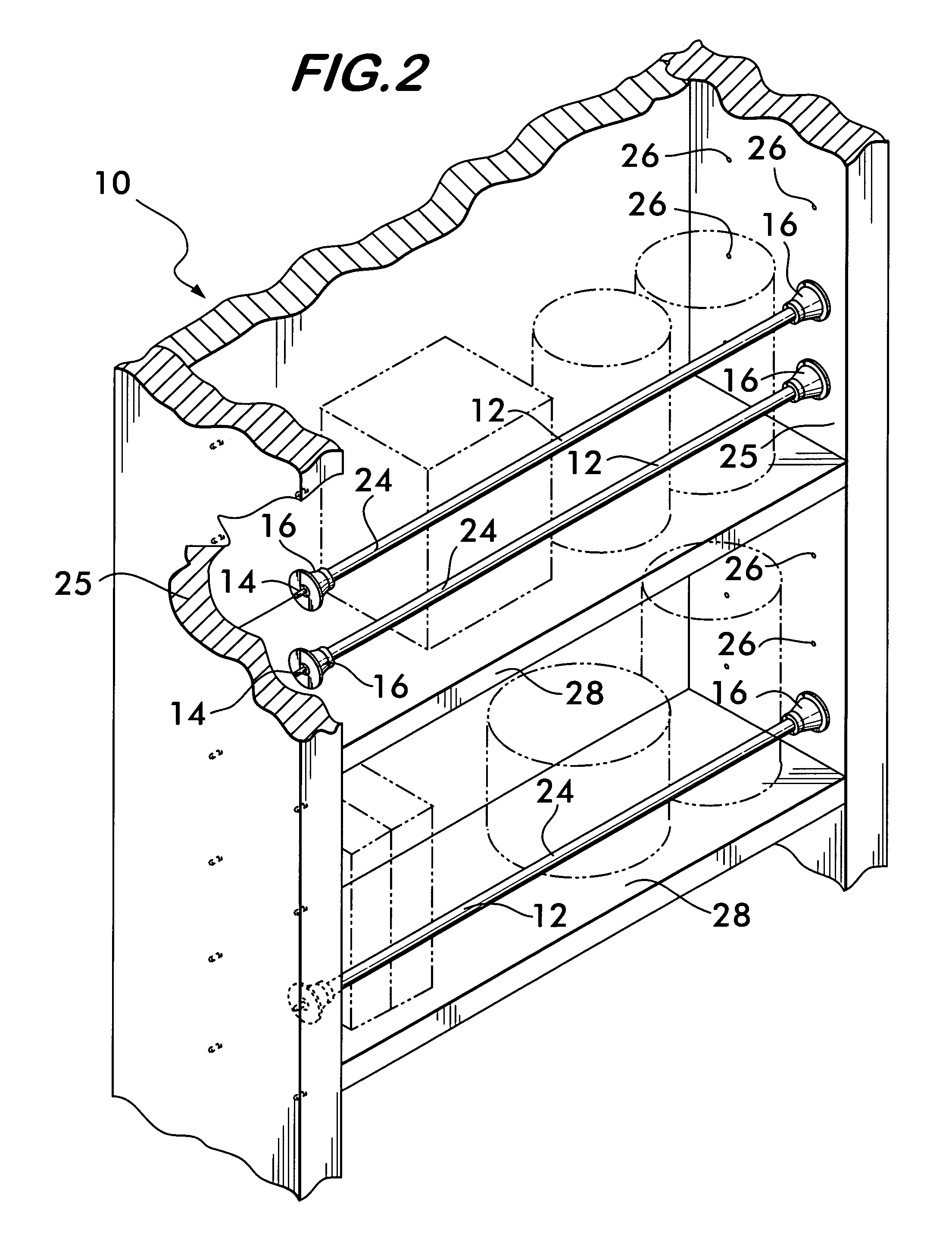

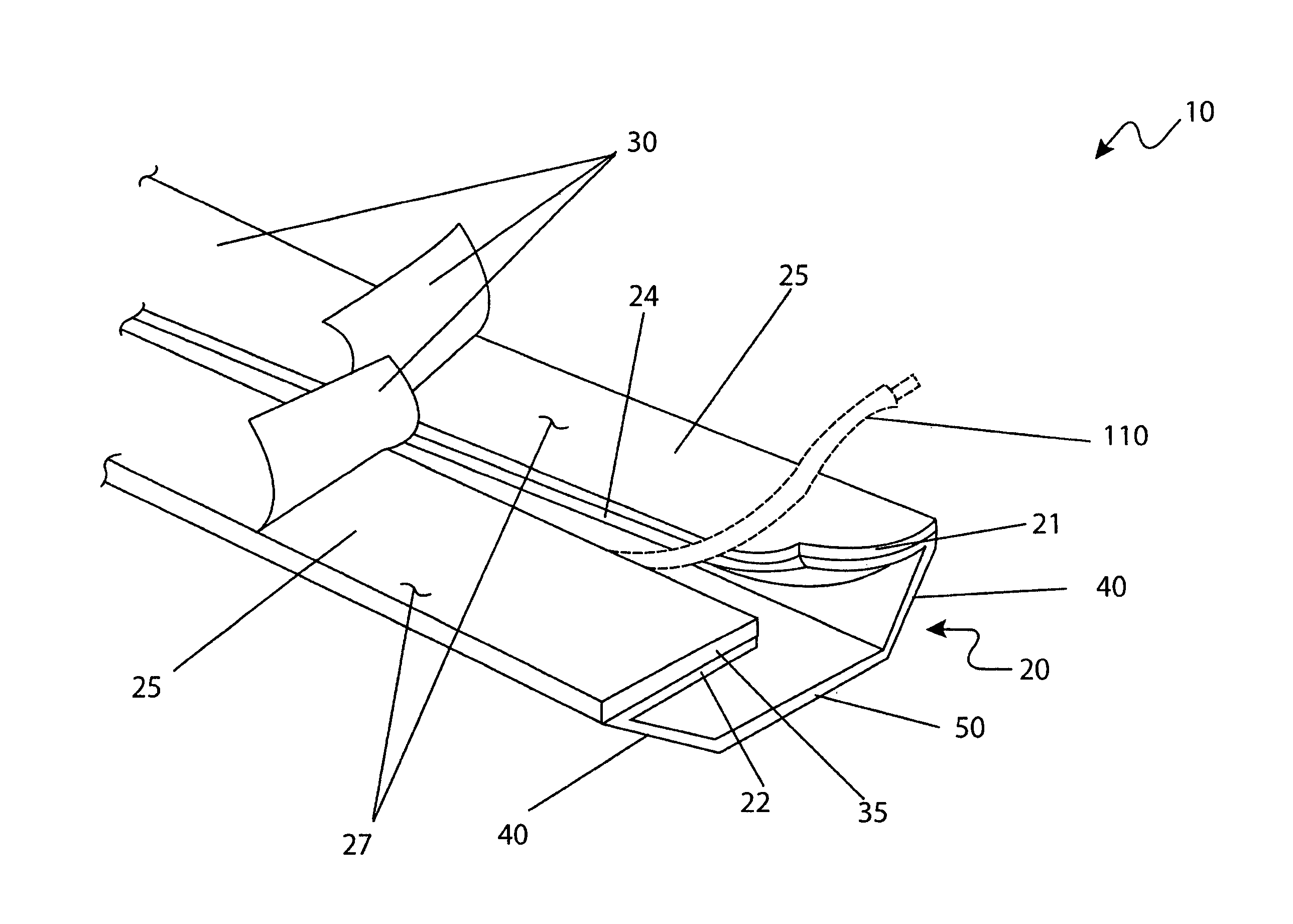

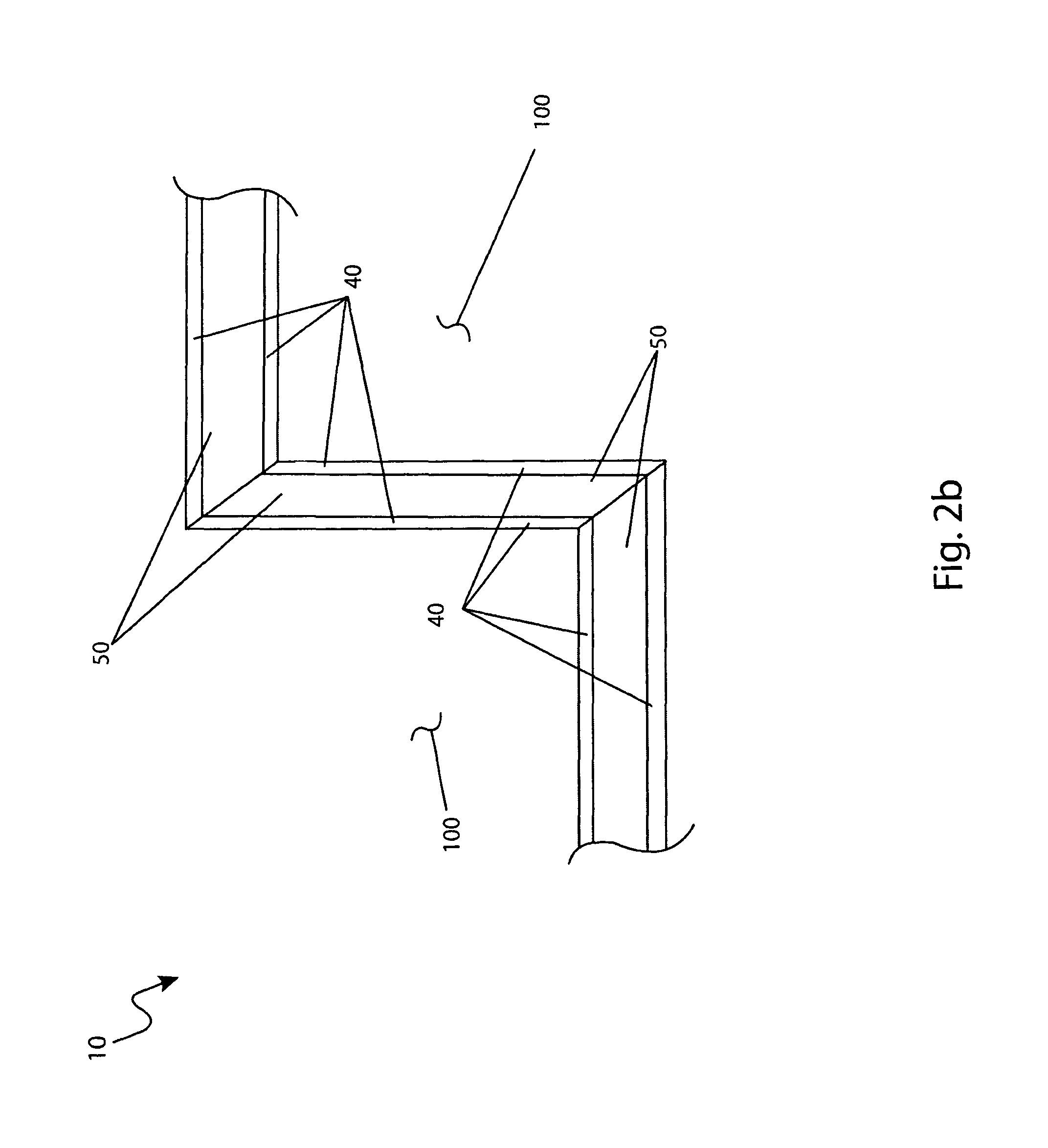

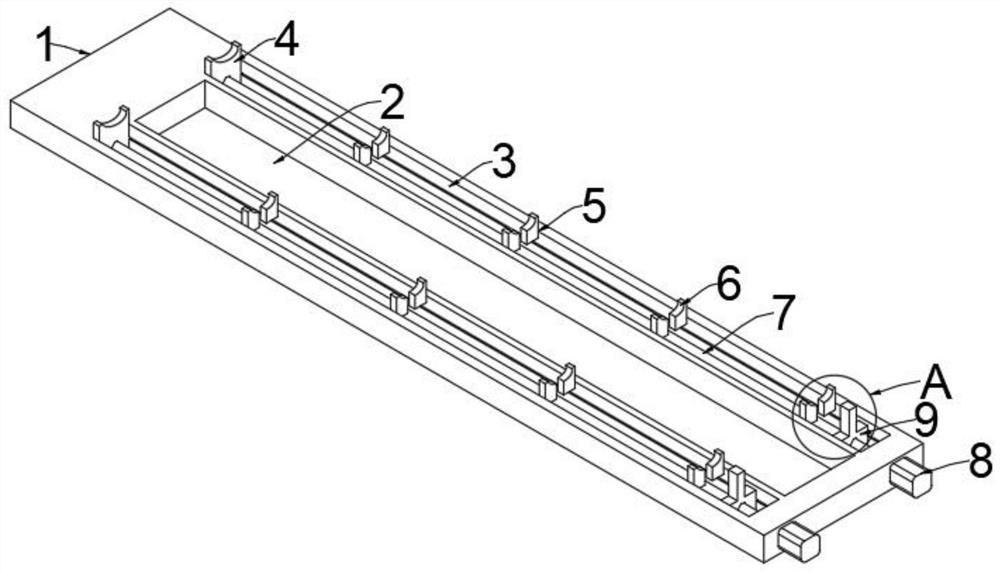

Organizing system for drawers and cabinets

InactiveUS6913156B1Exceptional simplicity and economyEasy to cut to lengthBook-troughsDrawersEngineeringMechanical engineering

An organizing system for drawers and cabinets for attachment to opposing walls is disclosed which includes at least one main support that includes a pair of holes in the opposing walls. The pair of holes are in opposing alignment with one another. The system further includes a pair of attachment pins. Each pin is pressed into one of the pair of holes in the walls. The head of the pin has a top surface. A primary support rod having two ends extends between the top surfaces of the heads of the pair of attachment pins such that an abutment point is created at each end of the primary support rod between each primary support rod end and the top surface of each attachment pin. Fittings slide over the abutment point to secure the primary support rod with respect to each attachment pin.

Owner:WOOD MODE

Apparatus for maintaining a tensioned pull-wire in an endoscope

ActiveUS9968241B2Less complicated to manufactureIncrease flexibilitySurgeryEndoscopesBowden cableEngineering

A control mechanism for an endoscope (1) comprising a Bowden cable. the Bowden cable has an outer guide tube (9) having a first length between a proximal end and a distal end of said outer guide tube (9) and an inner pull-wire (15) having a second length between a proximal end and a distal end of said inner pull-wire (15). The second length is longer than the first length. The outer guide tube (9) comprises a first guide tube section (9′) and a second guide tube section, where said first guide tube section (9′) has plastic and elastic properties, which are different from the plastic and elastic properties of said second guide tube section (9″).

Owner:AMBU AS

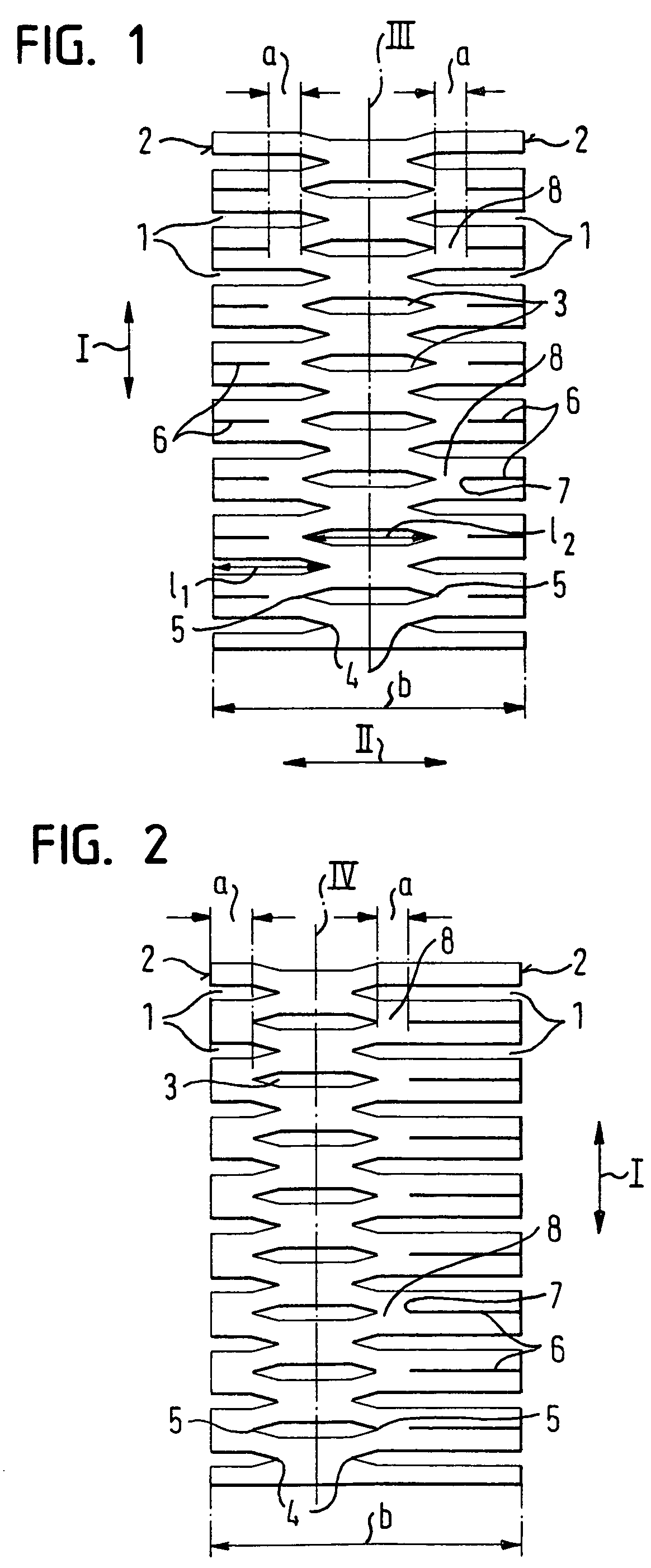

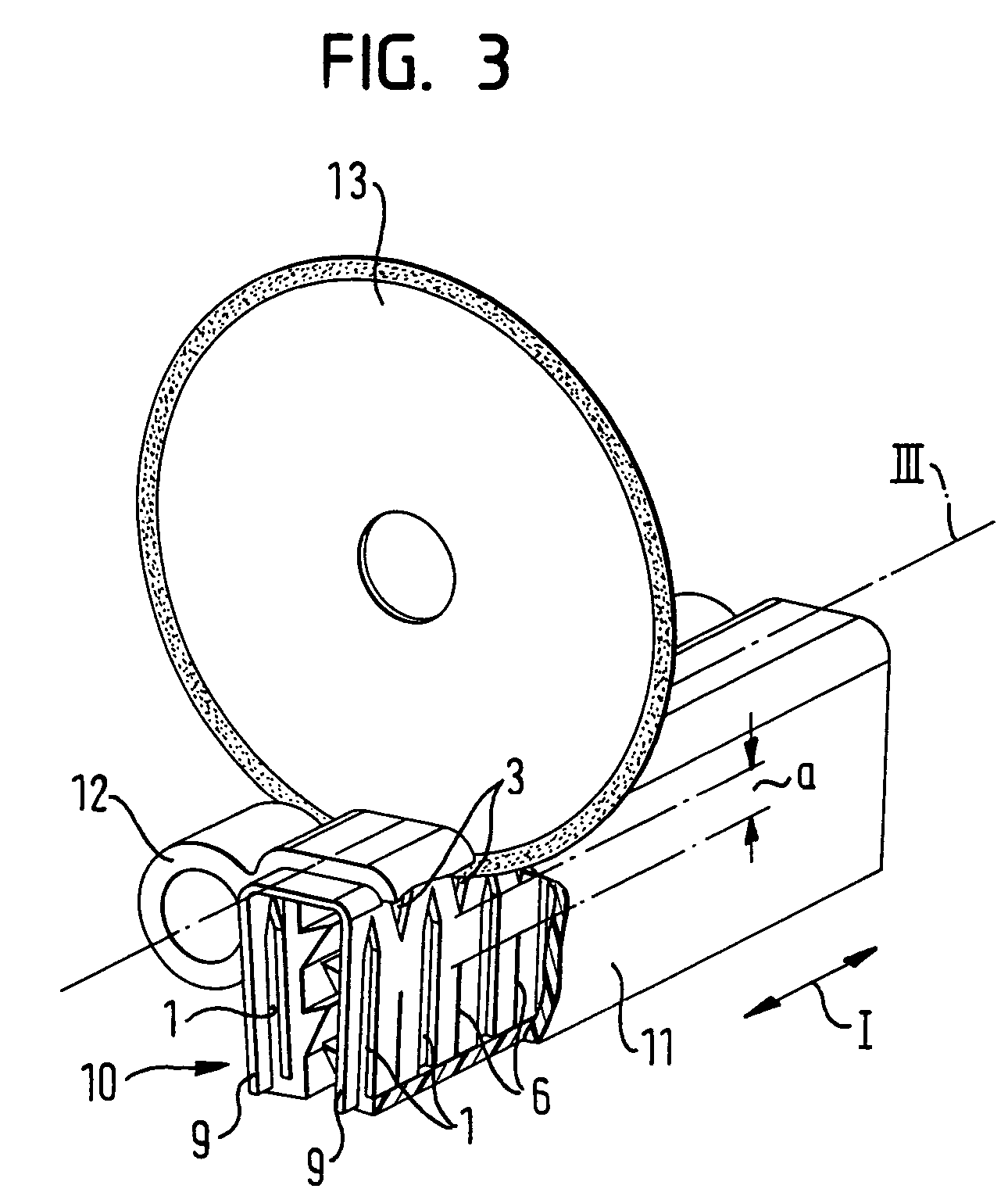

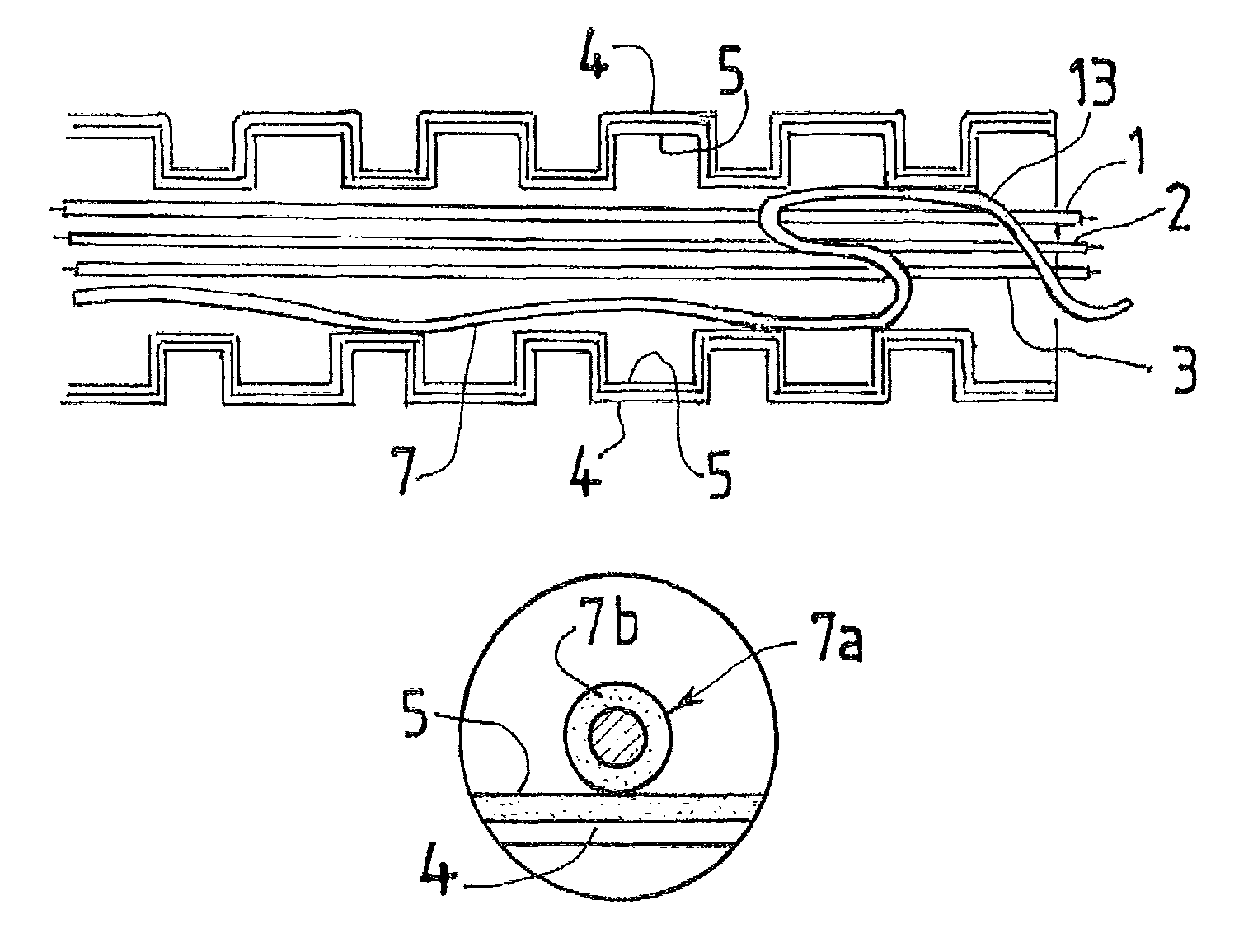

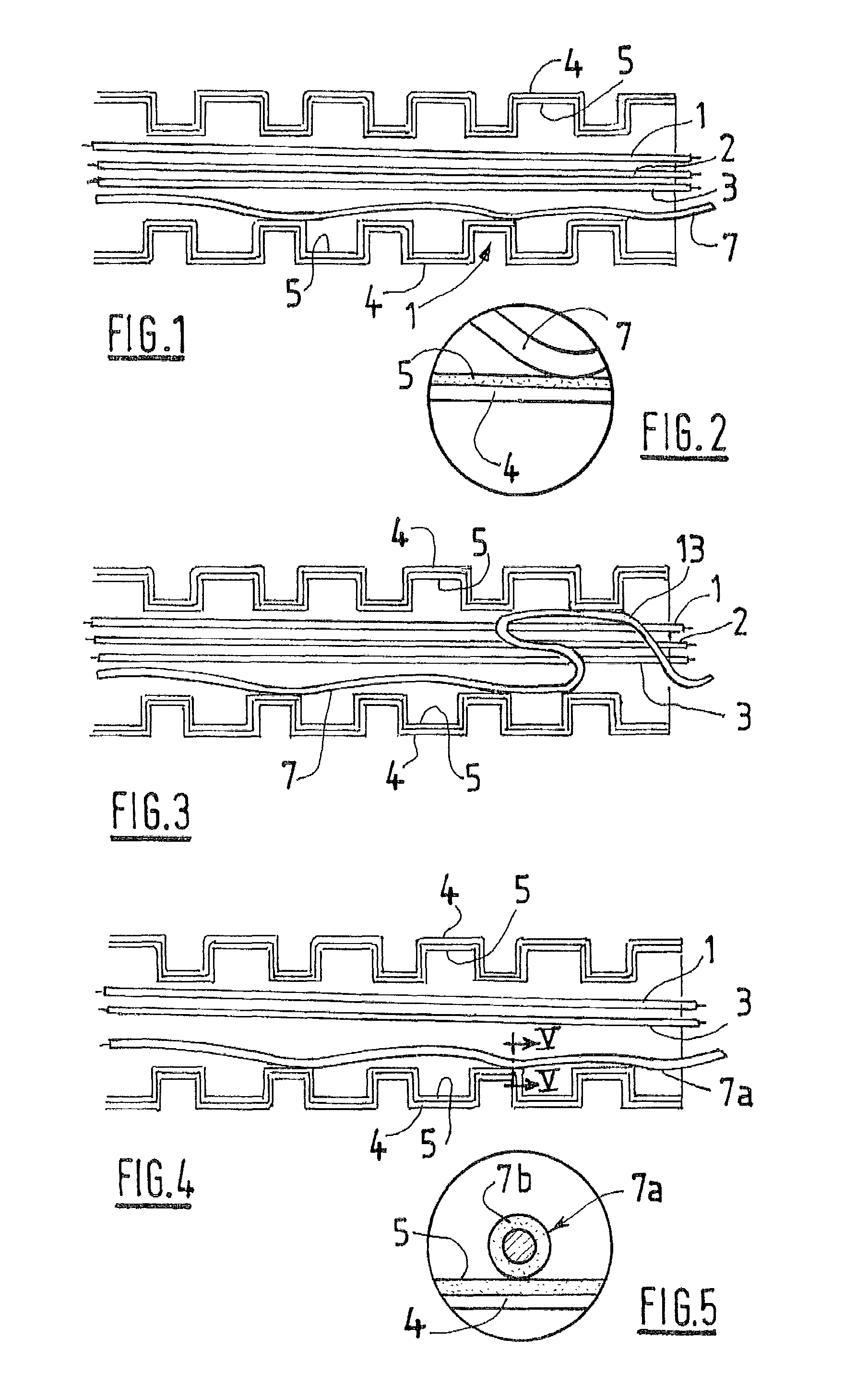

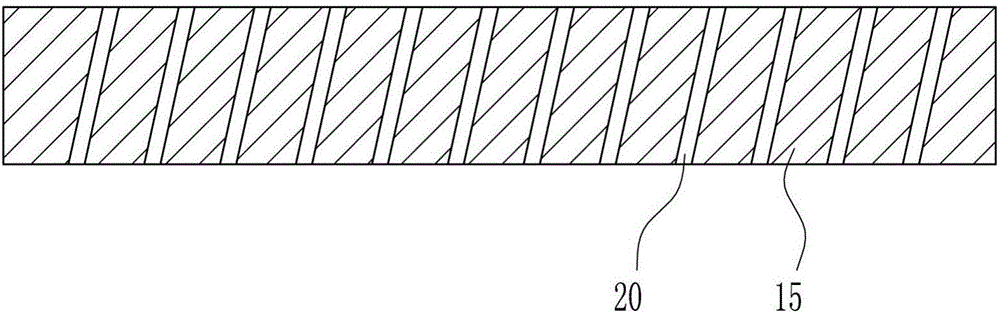

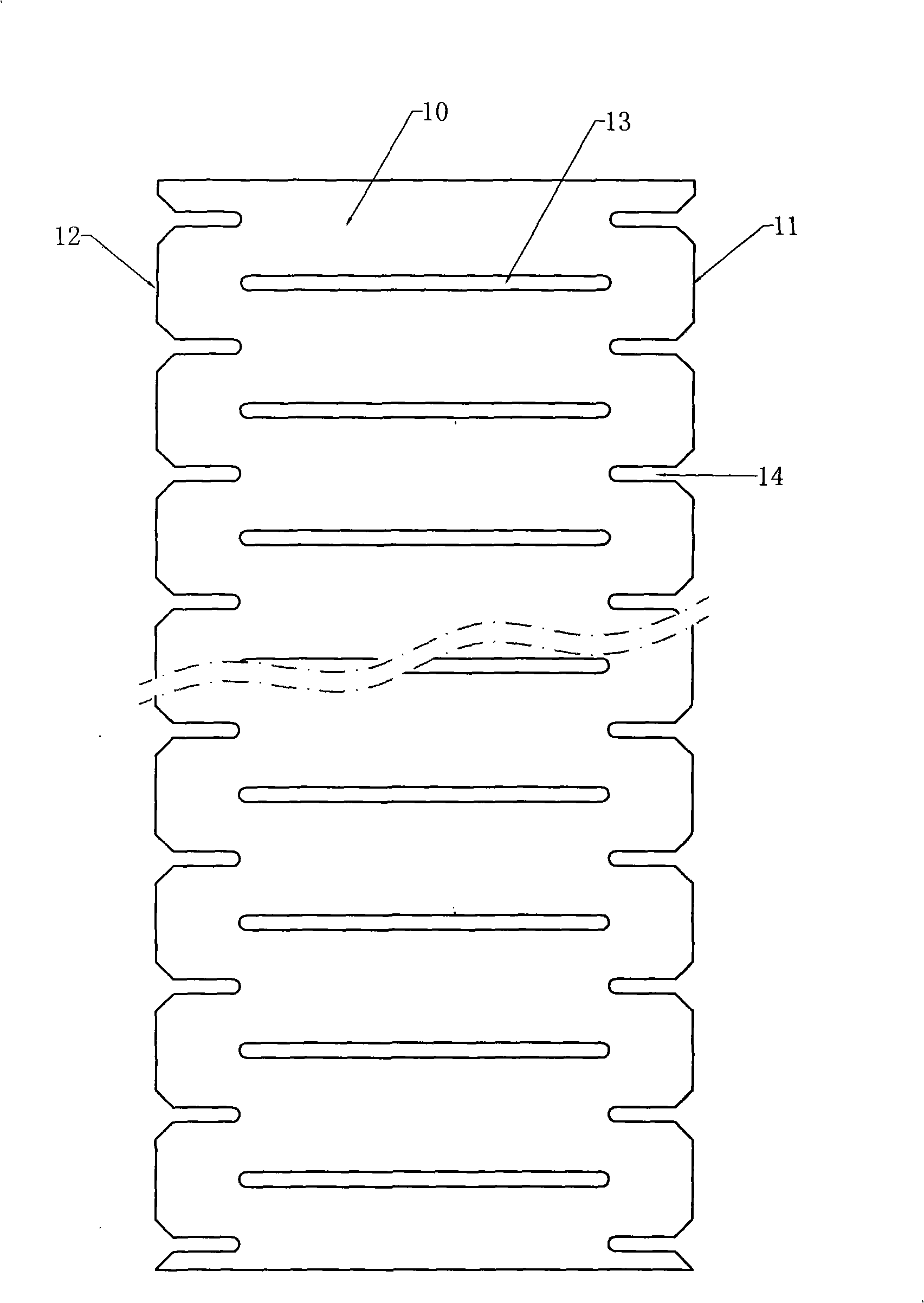

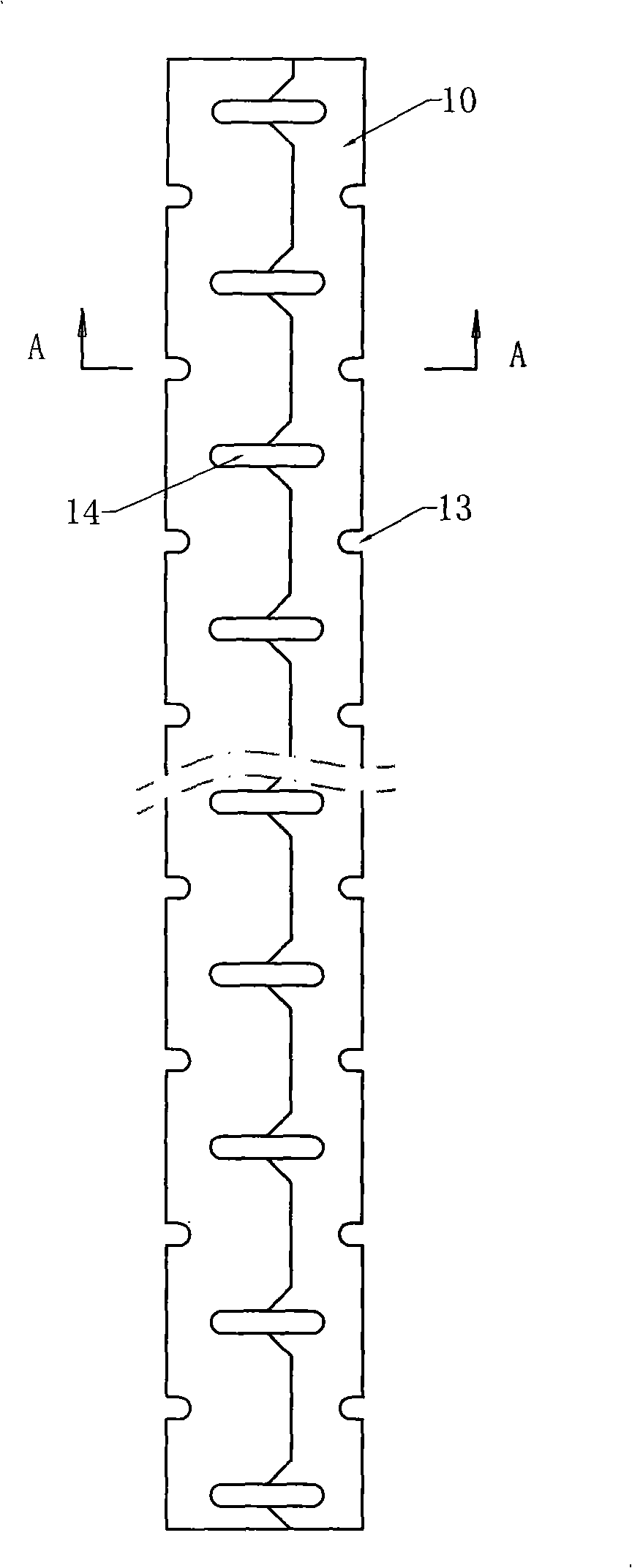

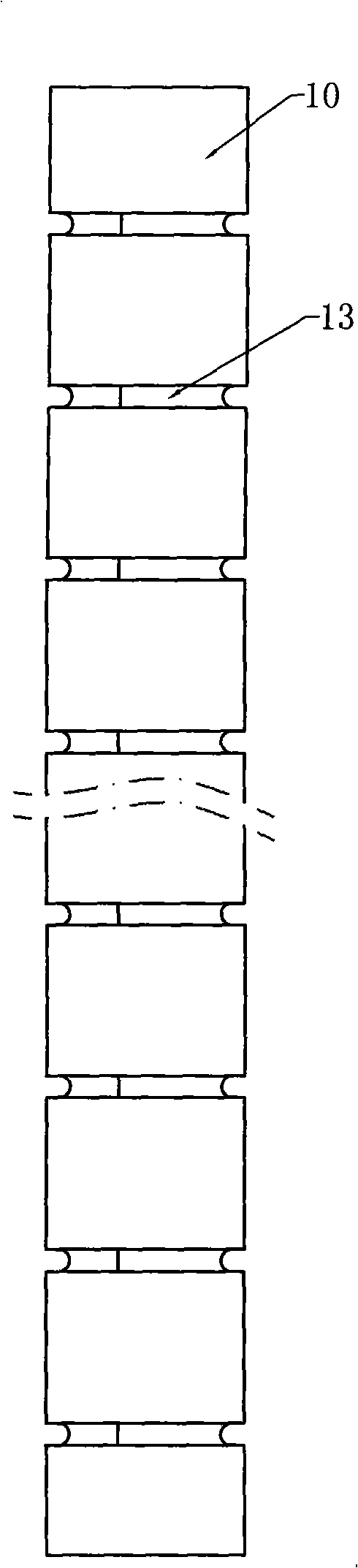

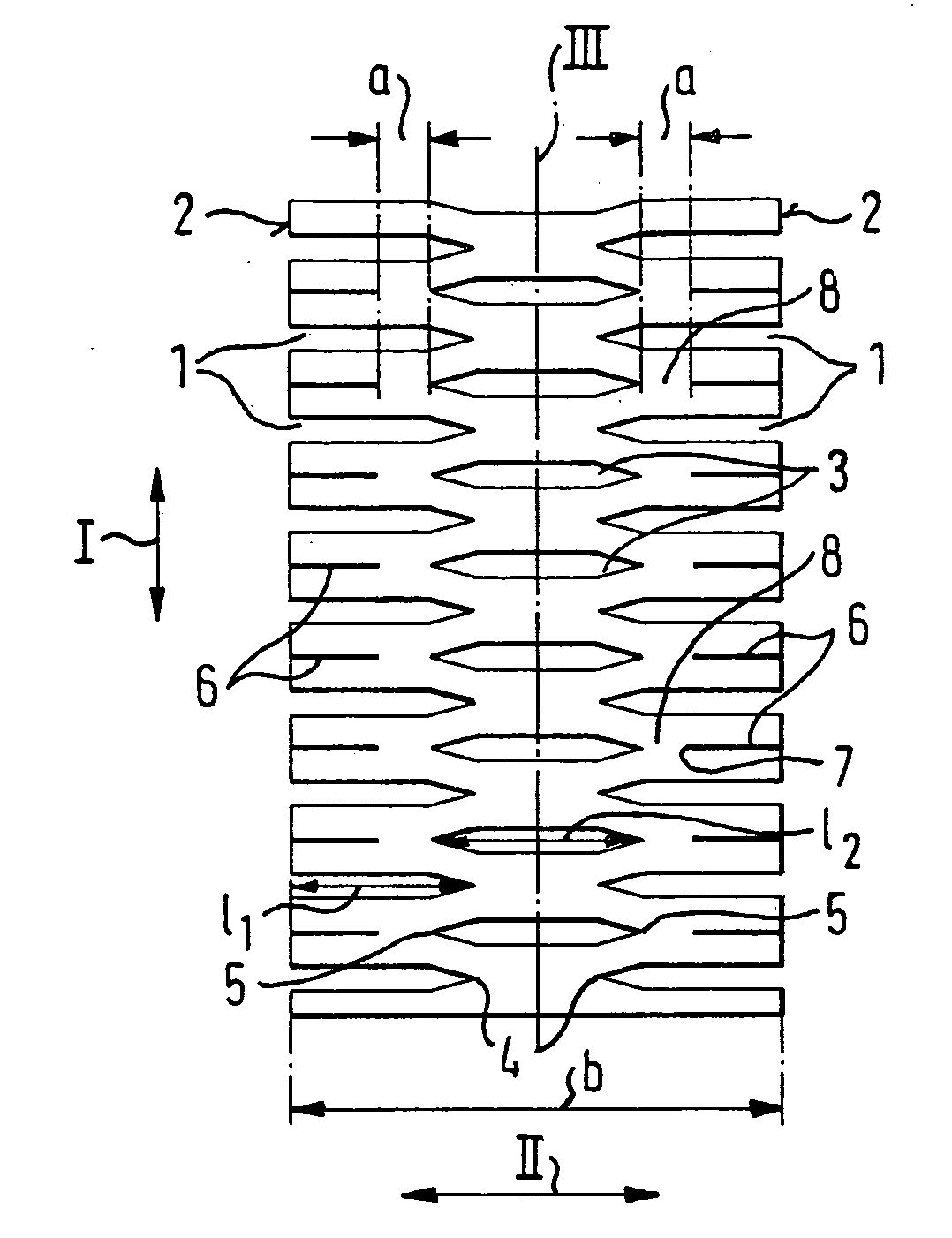

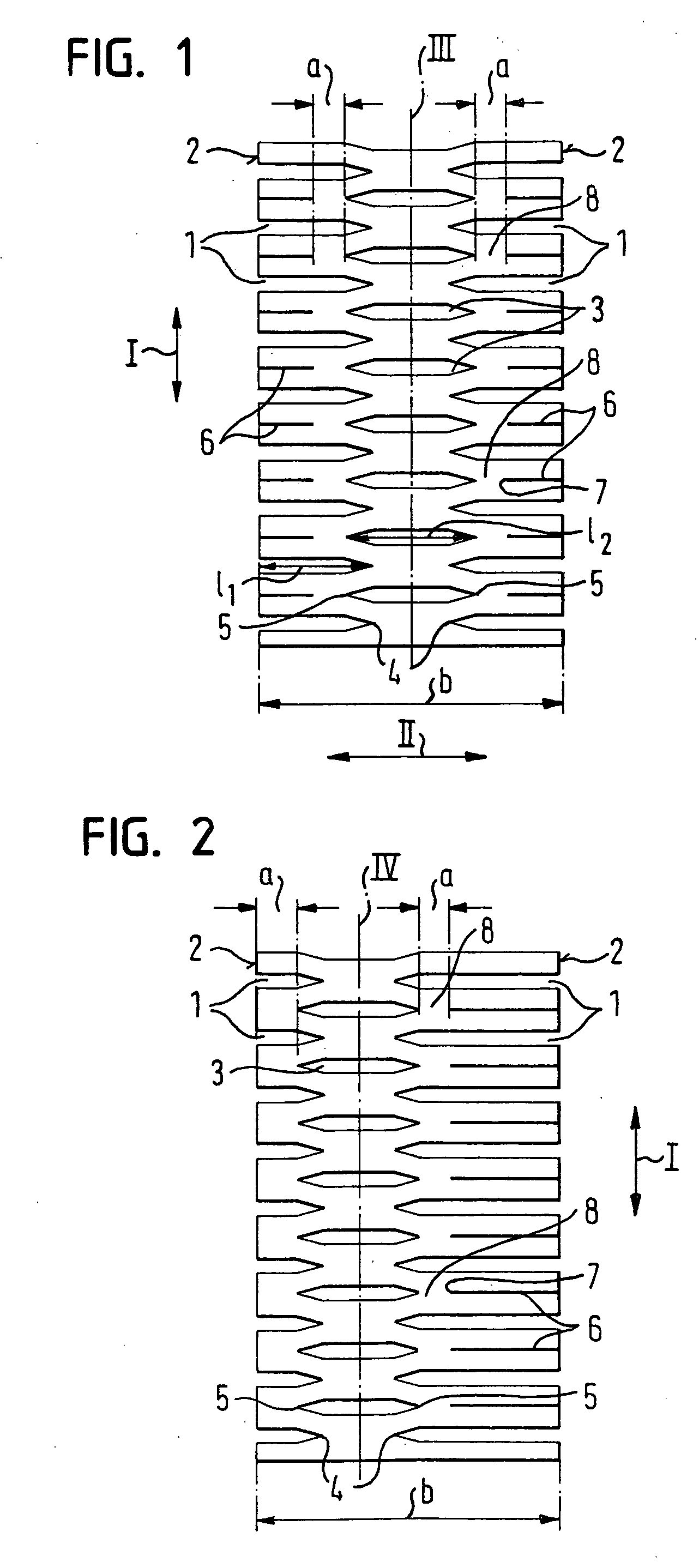

Metal band as inlay for trim strips or sealing strips

ActiveUS7517590B2Easy to cut to lengthReduce energy inputEngine sealsLayered productsEngineeringWedge shape

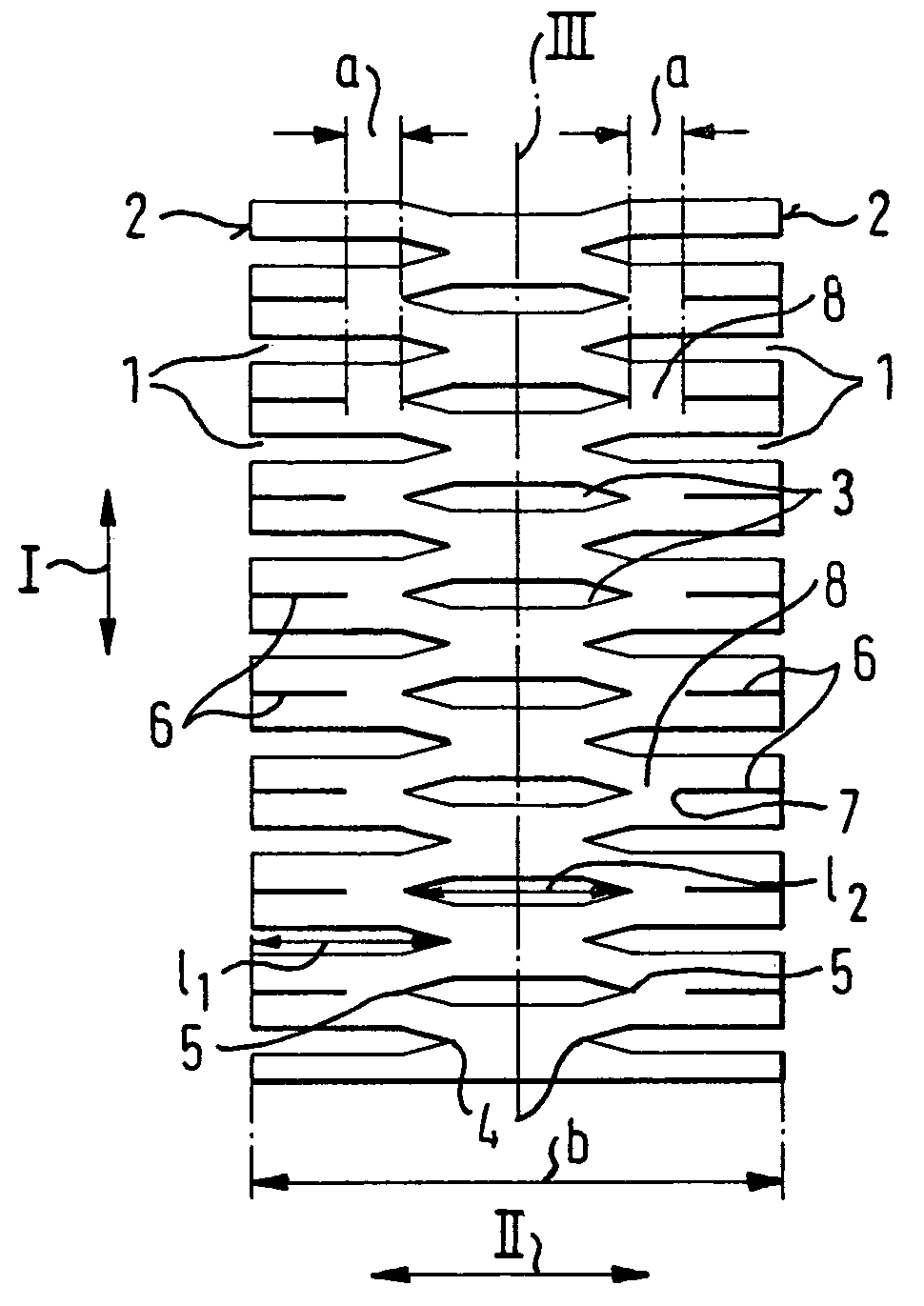

A metal band inlay for trim strips or sealing strips of flexible material that is bent to form a section. The metal band includes a plurality of edge slots in the longitudinal direction, which are guided inwardly from an edge of the metal band transversely to the longitudinal direction. The edge slots are wedge shaped. Central slots run to a tip toward their respective two ends and are arranged between the sequential edge slots. The central slots extend transversely to the longitudinal direction, but do not extend up to the edge. To simplify the cutting, the metal band further includes throughcuts that extend transversely to the longitudinal direction of the metal band, that correspond to at least some of the central slots and that extend from at least one edge of the metal band in the direction toward the tip of the respective central slot disposed opposite to the edge.

Owner:BFC FAHRZEUGTEILE GMBH

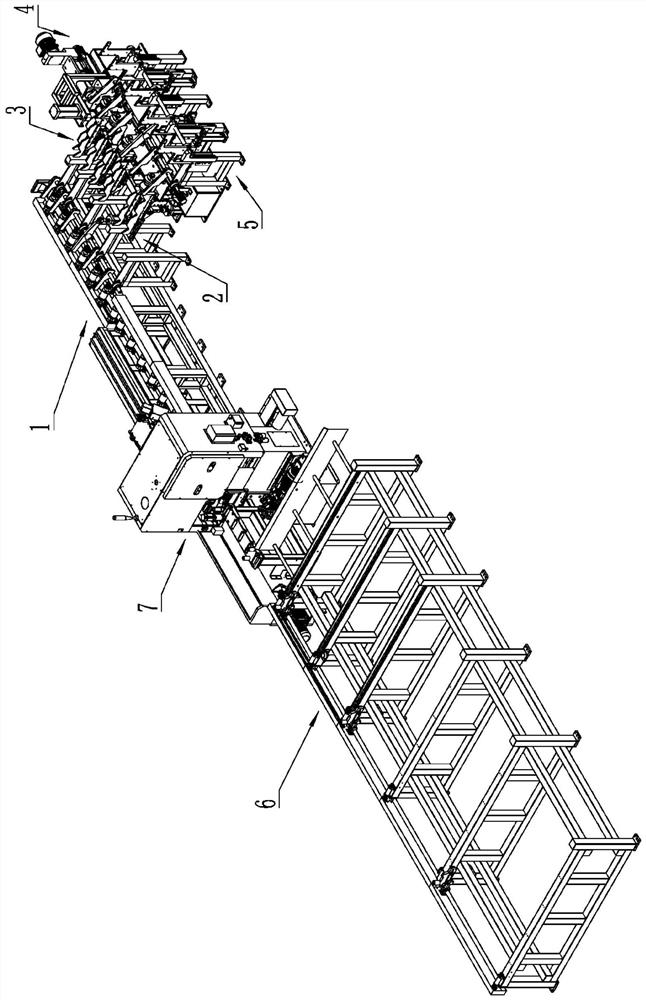

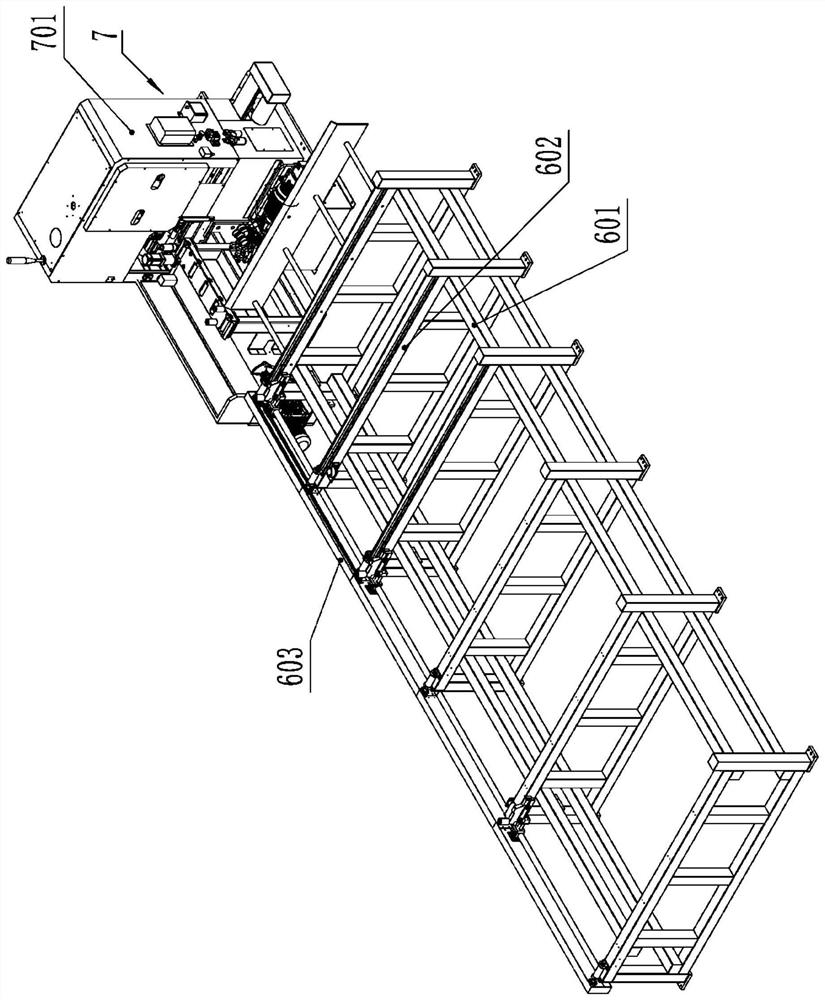

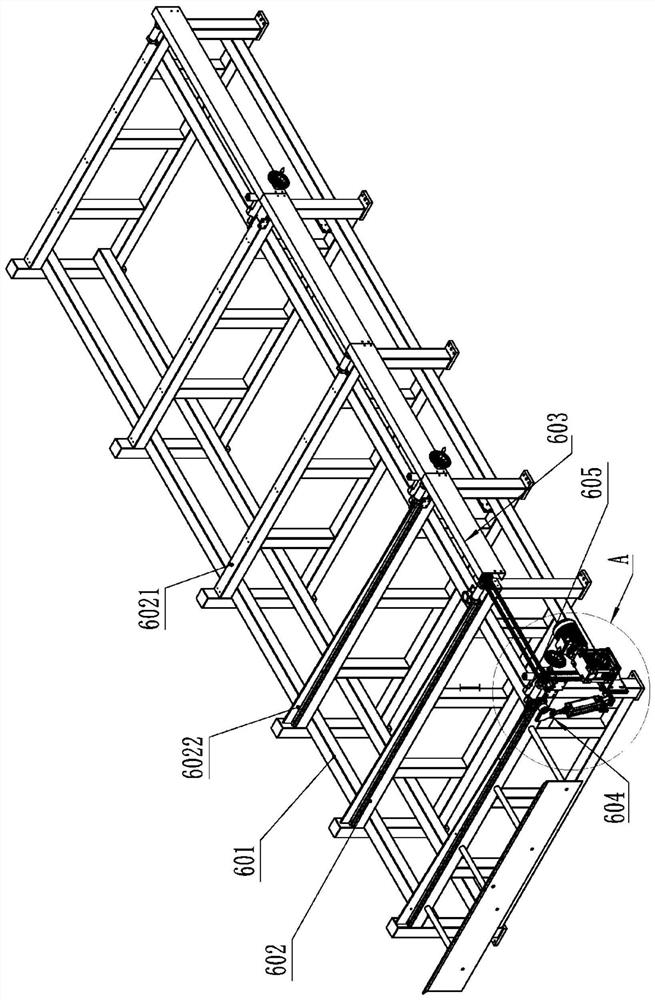

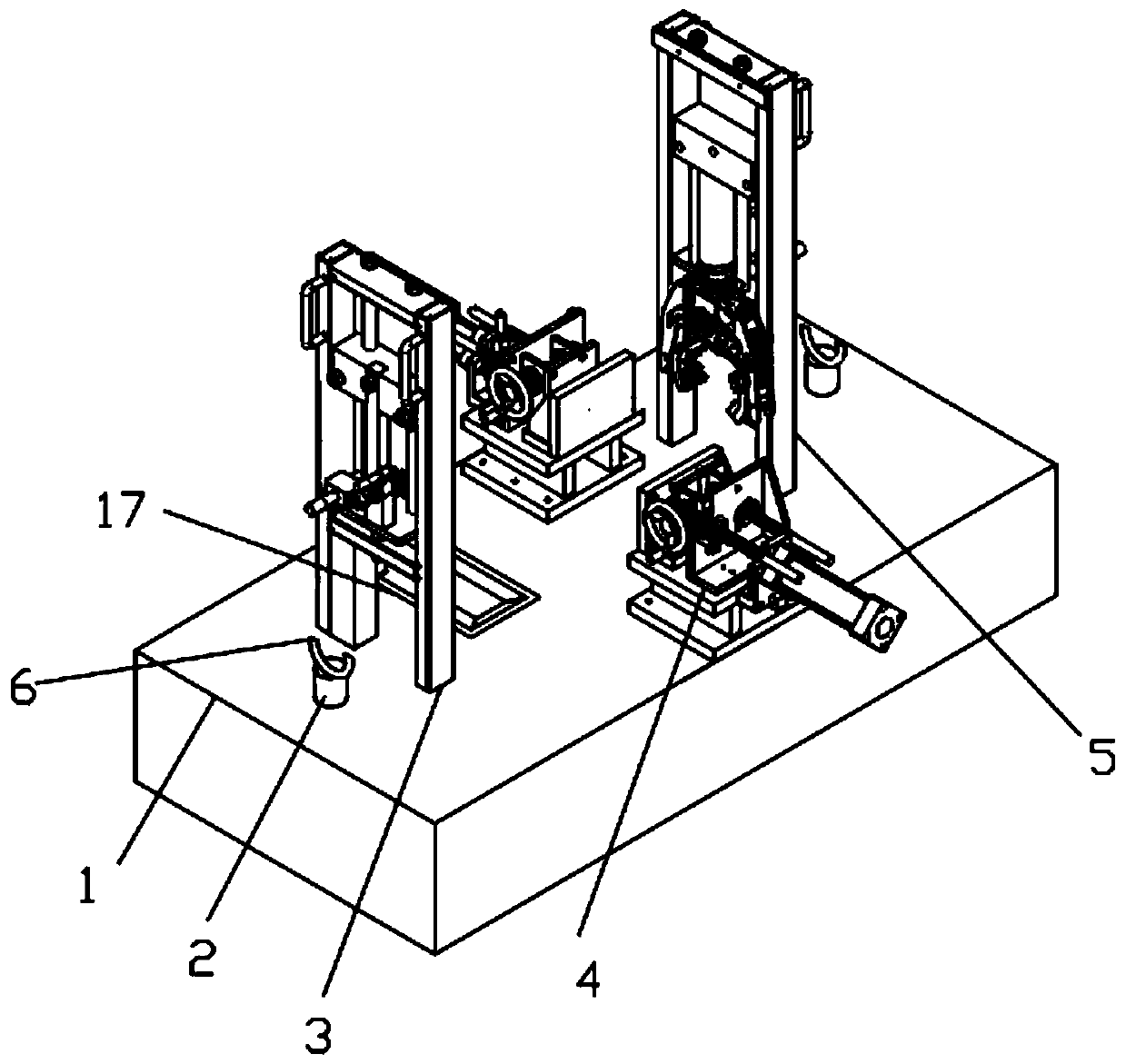

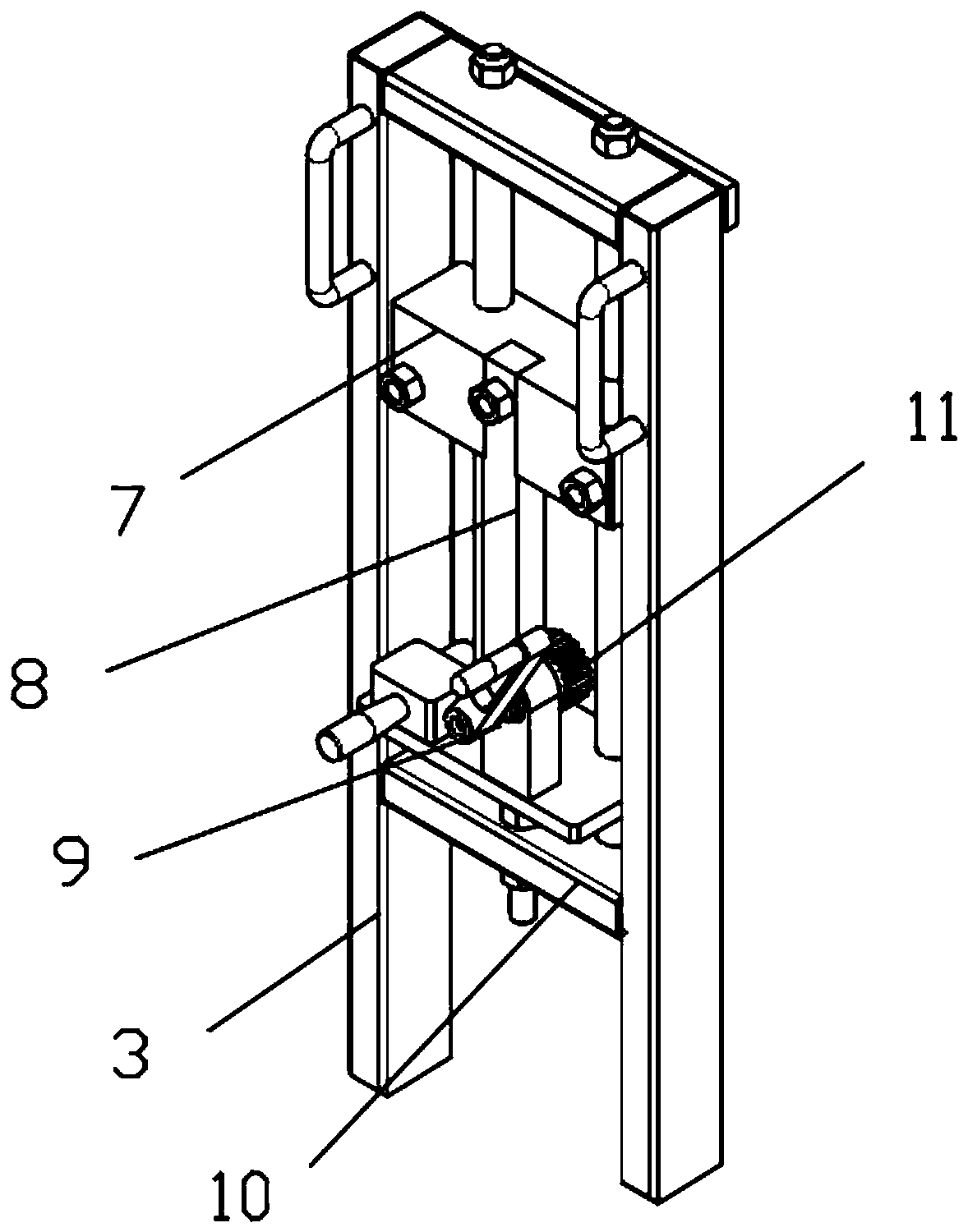

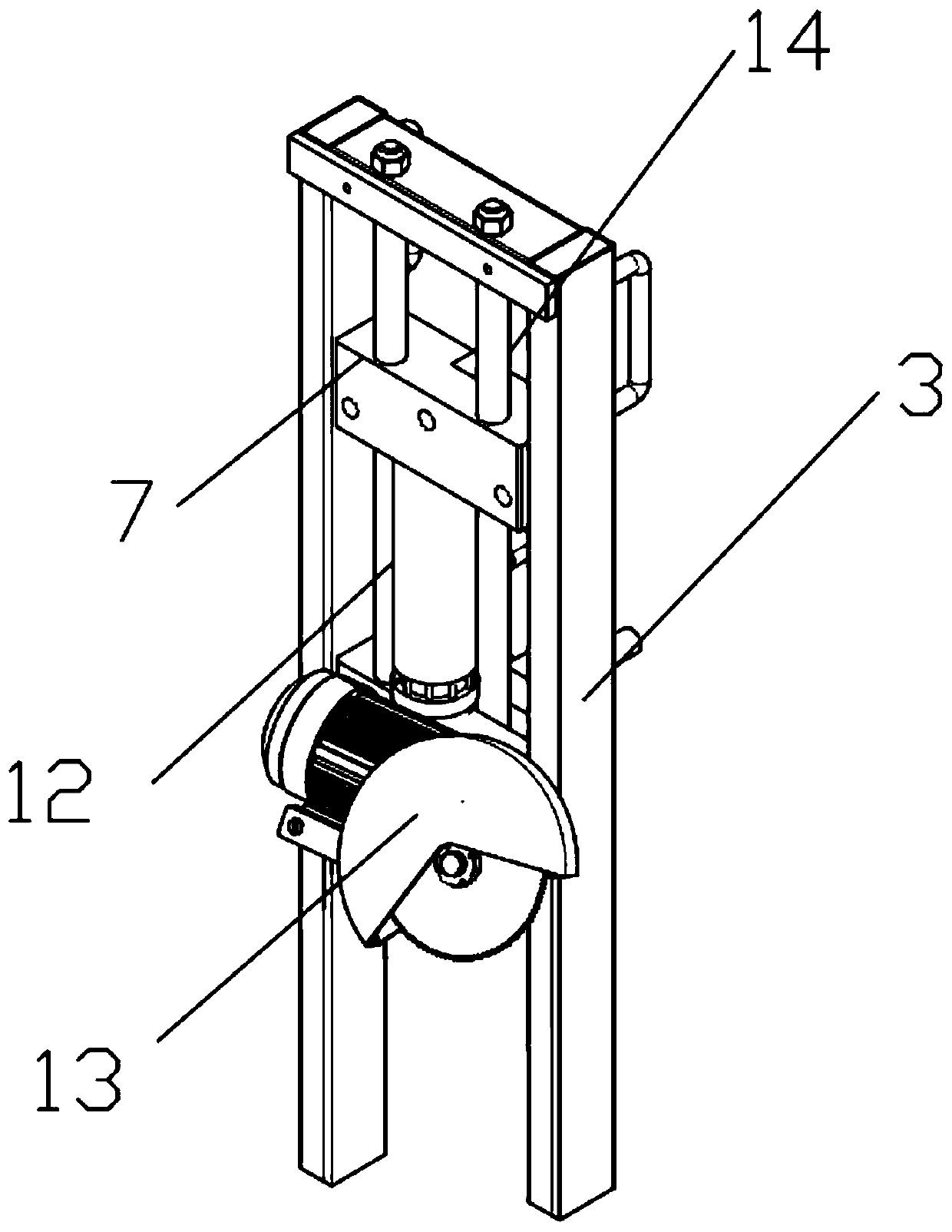

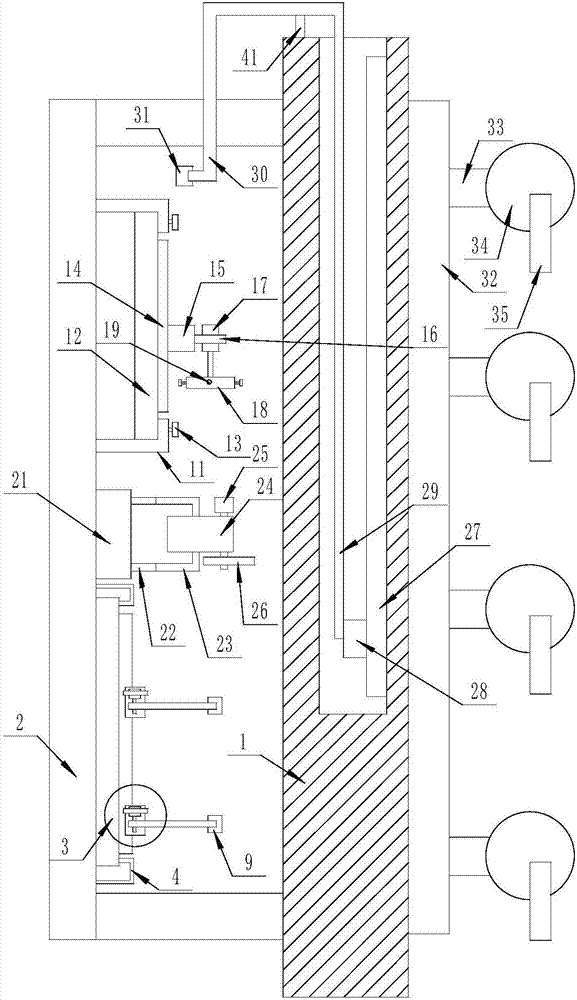

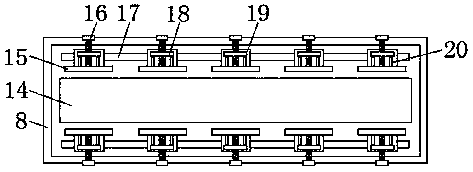

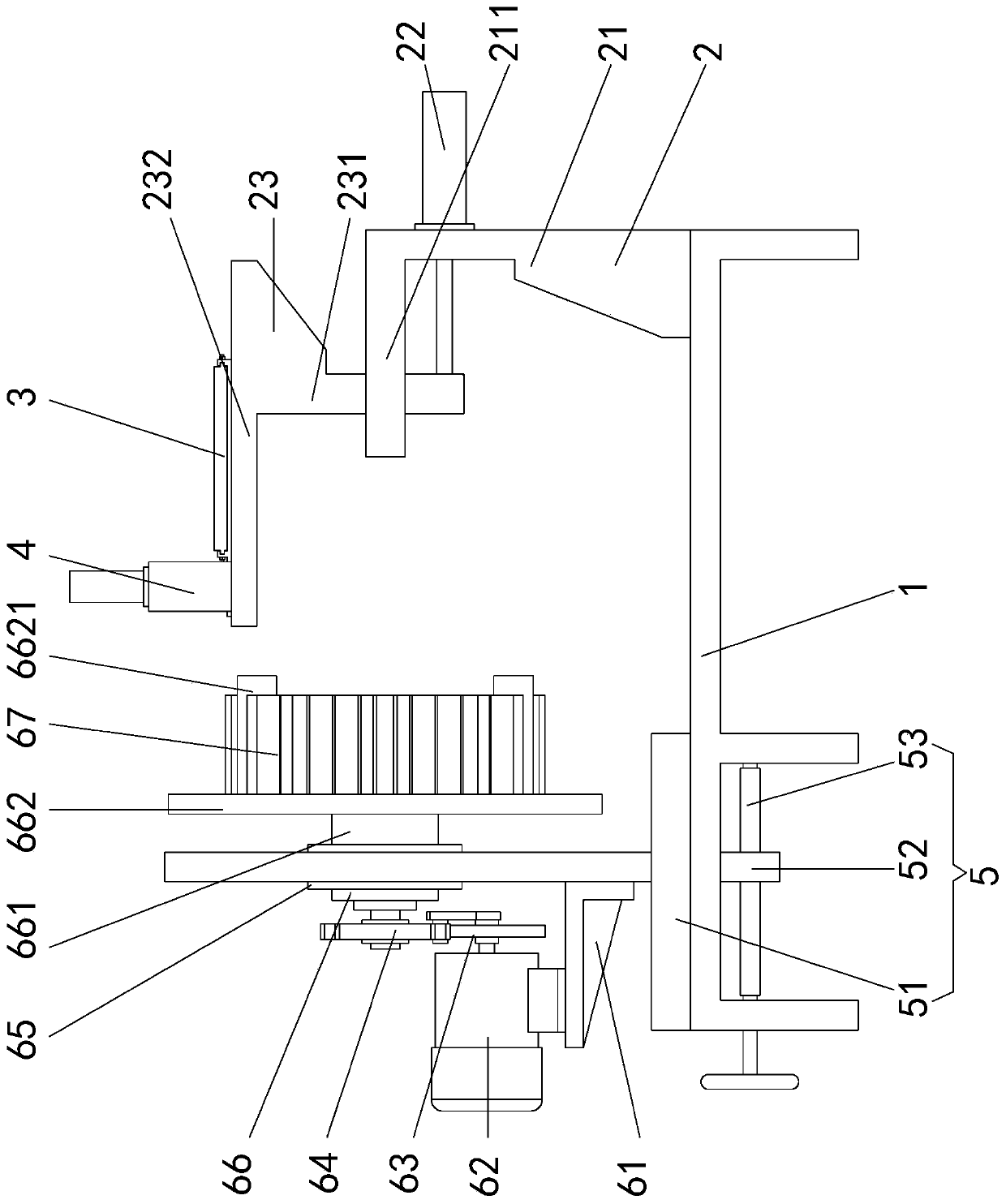

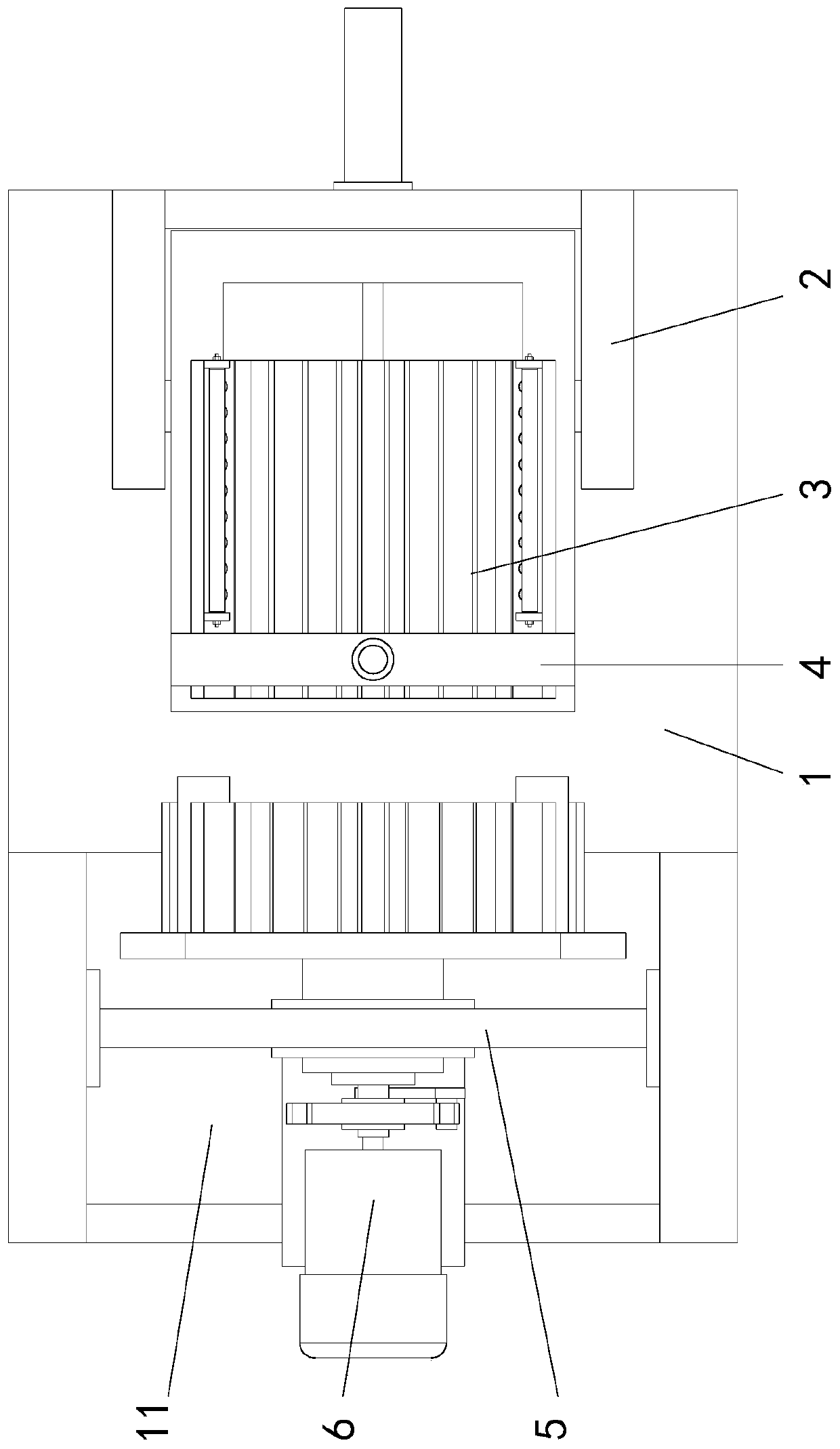

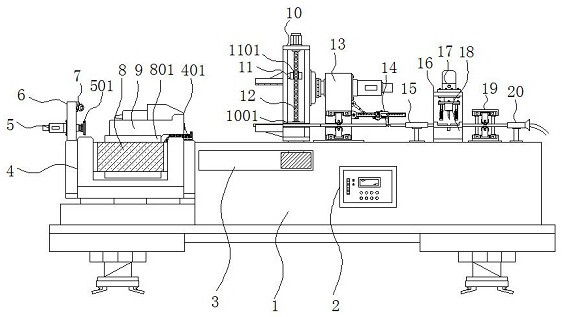

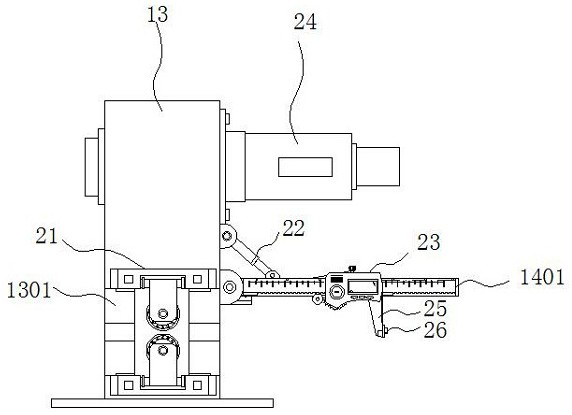

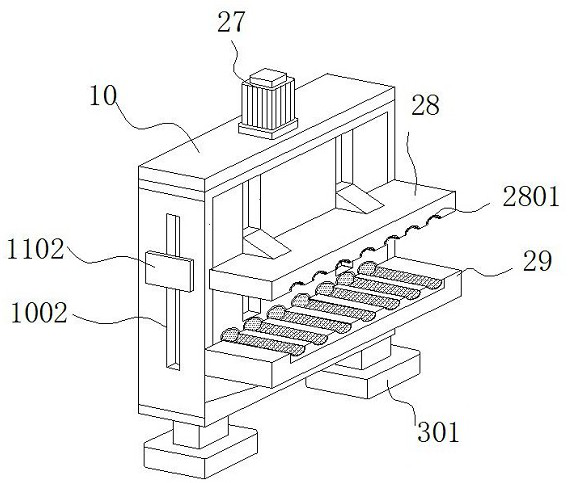

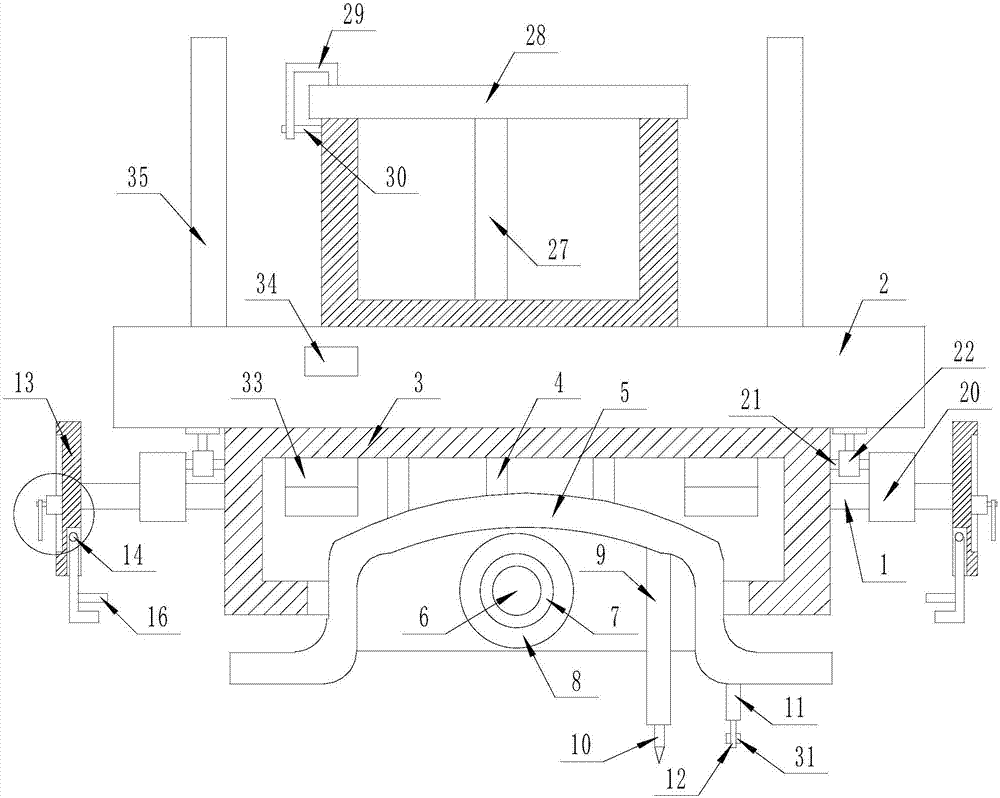

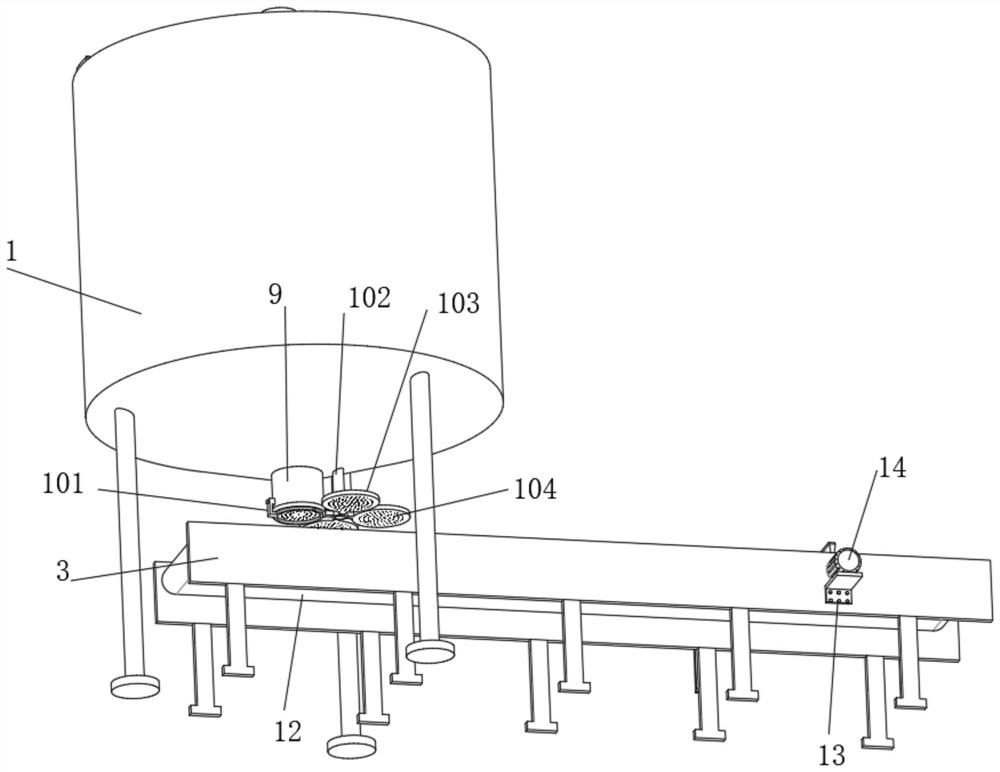

Short material sawing and drilling integrated production line

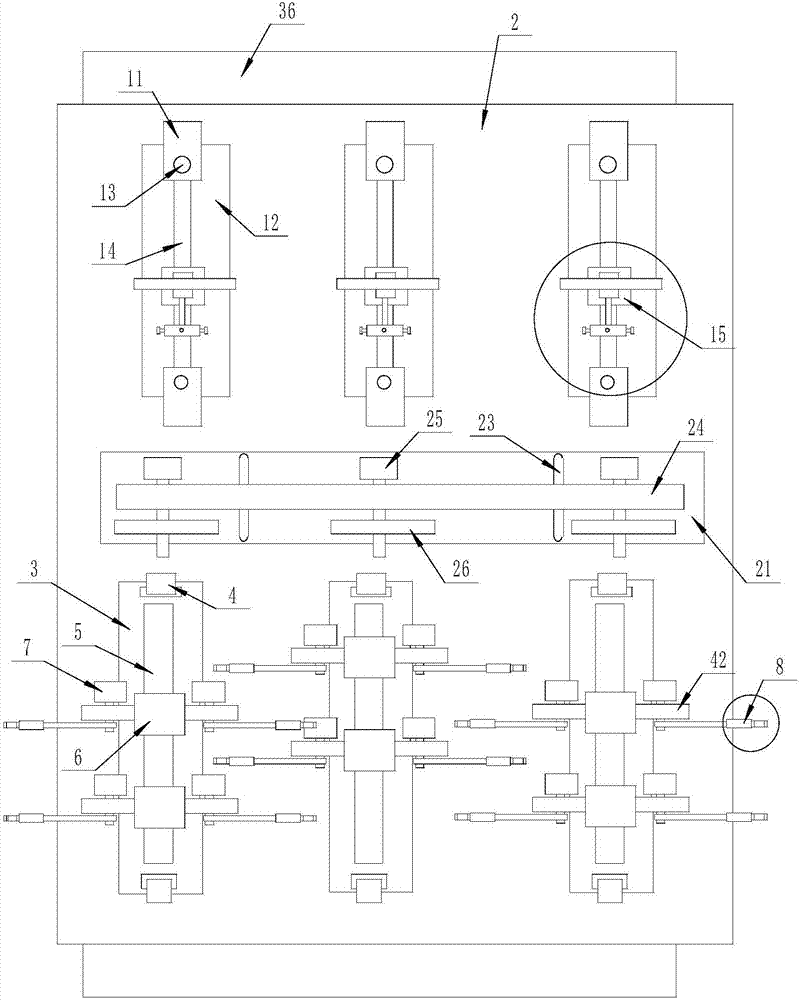

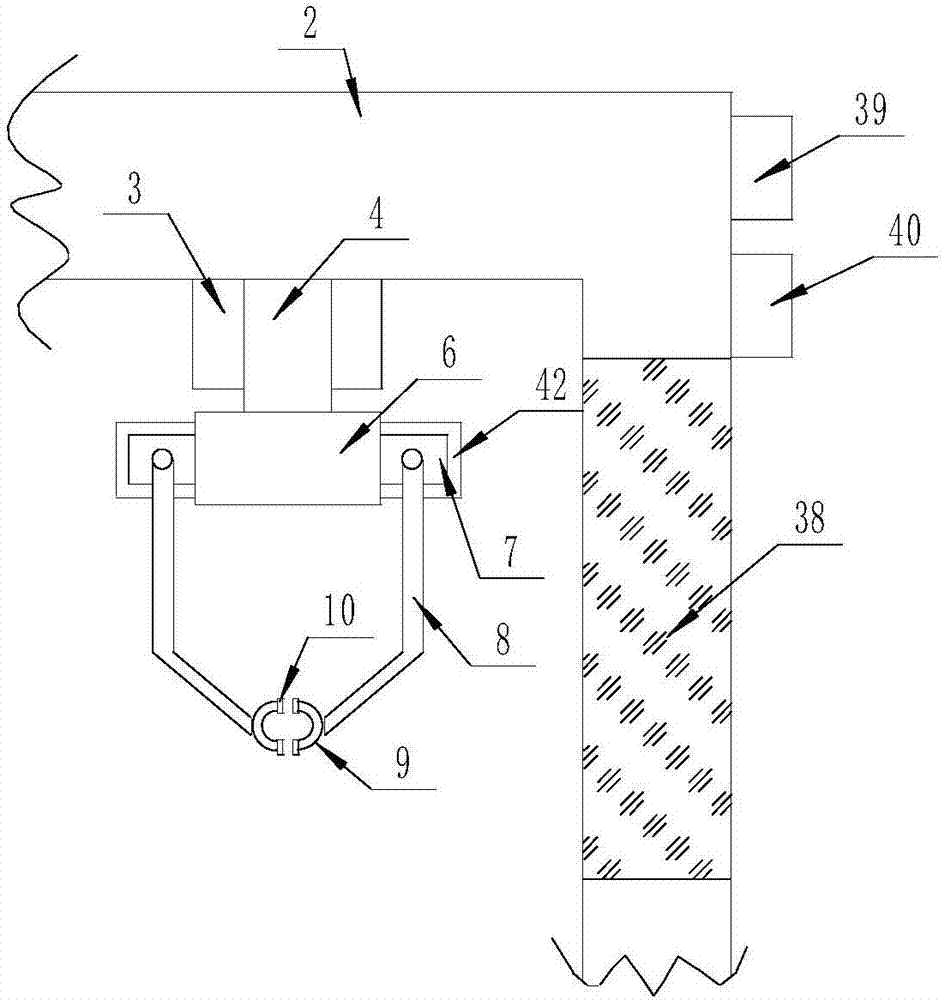

PendingCN112676840AEasy to sendRealize automatic feeding processOther manufacturing equipments/toolsStructural engineeringManufacturing line

The invention discloses a short material sawing and drilling integrated production line. The short material sawing and drilling integrated production line involves an upstream material overturning and conveying device, a sawing device, a sawing discharging conveying device, a transverse material overturning and temporary storage device, a transverse stepping feeding device, a drilling device and a drilling discharging device; the sawing device is used for sawing long material bars conveyed by the upstream material overturning and conveying device, and the sawing discharging conveying device is used for longitudinally conveying the sawn bars; the transverse material overturning and temporary storage device is used for transversely overturning and conveying the longitudinally-placed bars to a temporary storage material frame, and the transverse stepping feeding device is used for conveying the bars on a material taking station to a drilling supporting station in a stepping mode; the drilling device comprises a drilling machine base and a drilling supporting device, the drilling supporting device is used for supporting the bars, and a drill bit assembly and a drilling clamping device are longitudinally arranged on the drilling machine base in a sliding mode; and the drilling discharging device is used for sending out the bars on the drilling supporting device. According to the short material sawing and drilling integrated production line, the long material bars are automatically fed and supplied to the sawing device to be sawn, and then the long material bars are automatically conveyed to the drilling device to be subjected to end face drilling, so that continuous automation of sawing and drilling of the metal bars is completed, and the efficiency is improved.

Owner:SUZHOU KINKALTECK MACHINERY TECH

Sheath providing protection against radiation, in particular from the electric field generated by electric cables

InactiveUS8536450B2Smooth connectionEasy to cut to lengthMagnetic/electric field screeningInsulated cablesElectricityPower grid

A sheath is disclosed which provides protection against radiation. The sheath surrounds or is configured to surround at least a neutral cable, a earth cable and a phase cable which are all connected to the power grid. The sheath includes an outer layer made from electrically insulating plastic which covers an inner layer made from electrically conductive material, elements being provided to connect the layer of electrically conductive material to an electrical conductor intended to be earthed. The conductor to be earthed takes the form of a wire, all or part of which is made from electrically conductive material that extends internally along the entire length of the sheath and which is in electrical contact, at least along part of the length thereof, with the inner layer of electrically conductive material.

Owner:RAYPONSE

Adhesive wire molding

InactiveUS8203078B1Easy to cut to lengthFlexible pipesConnection contact member materialEngineeringLarge size

A conduit with a self-adhesive backing used to route and organize electrical or electronic cables along wall surfaces is herein disclosed. The conduit comprises a trapezoidal-shaped enclosure available in multiple widths from approximately two (2) inches up to six (6) inches. The smaller size would be used for one (1) or two (2) cables while the larger size conduit could be used with up to ten (10) cables. The rear or flat side of the conduit would be fastened to the wall surface using a pre-applied double-sided foam adhesive tape. The tape would be covered with a common release paper which would be peeled off just before application. The back section of the conduit would also be pre-split down the center to aid in the installation of wires and cable during initial installation. The conduit comprises a flexible material such as plastic or rubber to allow routing along irregular wall surfaces and can be cut to length with regular household scissors. It is envisioned the conduit may be introduced in multiple colors to match various decors and can also be painted to match existing wall surfaces.

Owner:FULCO SUSAN

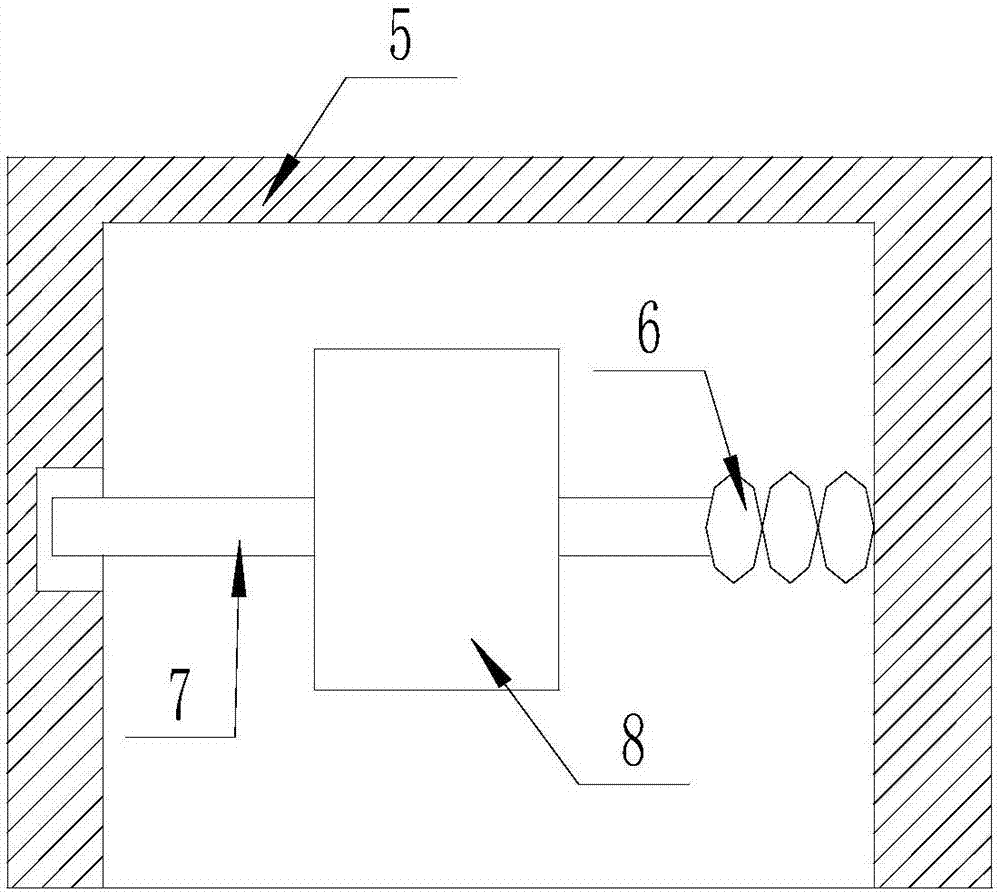

Fixed-length cutting equipment for watchband leather of smart watch

ActiveCN106591500APrevent crushingSimple structureLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringFixed length

The invention relates to cutting equipment, in particular to fixed-length cutting equipment for watchband leather of a smart watch. By adoption of the fixed-length cutting equipment for the watchband leather of the smart watch, the effect of length control can be achieved. For achieving the effect, the fixed-length cutting equipment for the watchband leather of the smart watch comprises a left bearing seat, a left nut, a first lead screw, a cutting frame, a connecting block, a second lead screw, a right nut, a right bearing seat, a servo motor, a left electric push rod and the like. A left supporting rod and a right supporting rod are connected to the bottom of the interior of the cutting frame in a bolted mode, and the left supporting rod is arranged at the right side of the right supporting rod. A collection frame is arranged in the middle of the bottom of the interior of the cutting frame. A fixing device is arranged at the top end of the left supporting rod. By adoption of the fixed-length cutting equipment for the watchband leather of the smart watch, the effects of simple structure, ingenious design and convenient fixed-length cutting are achieved; and operation is easy and convenient, and the practicability is high.

Owner:徐州润金新能源技术研究院有限公司

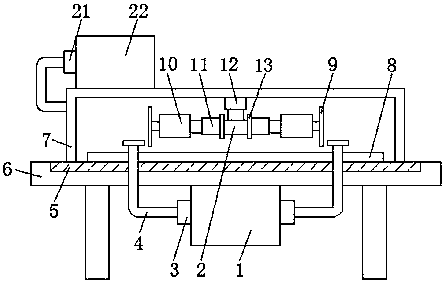

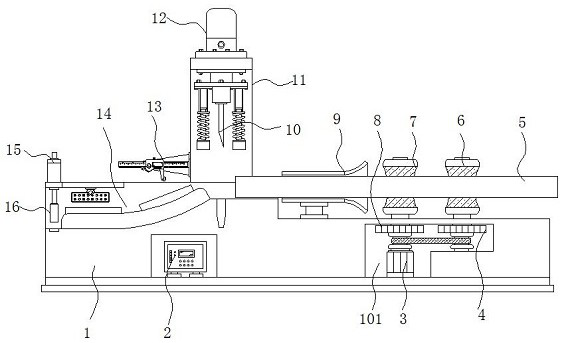

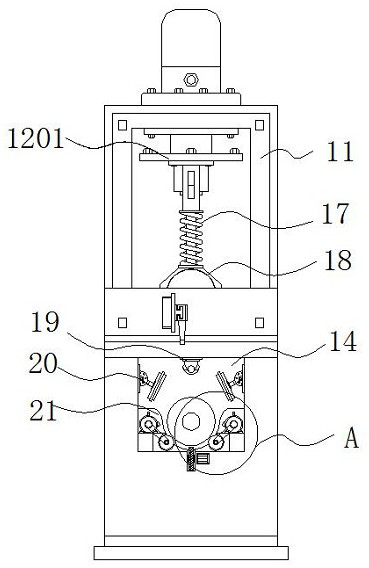

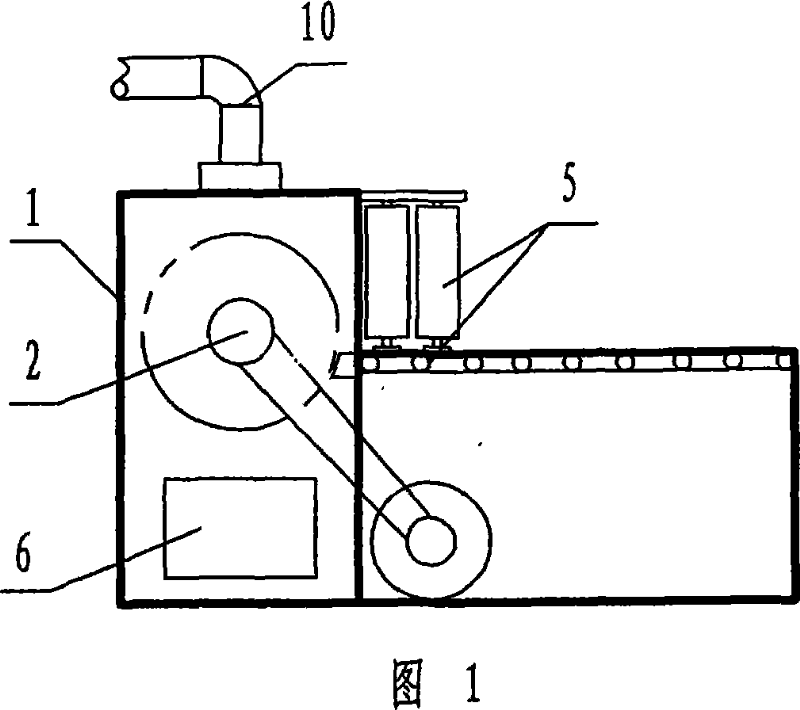

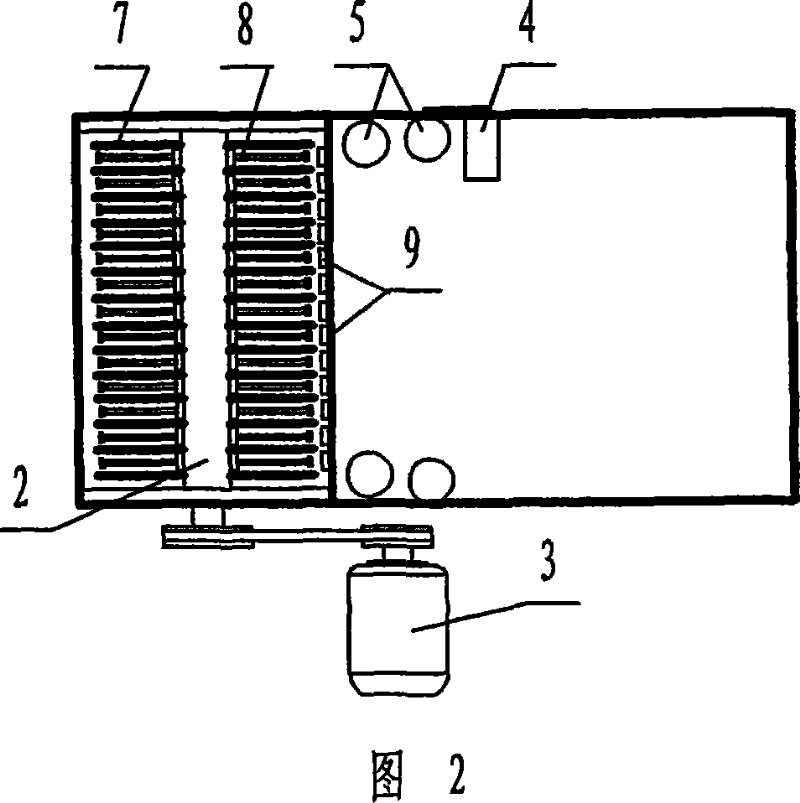

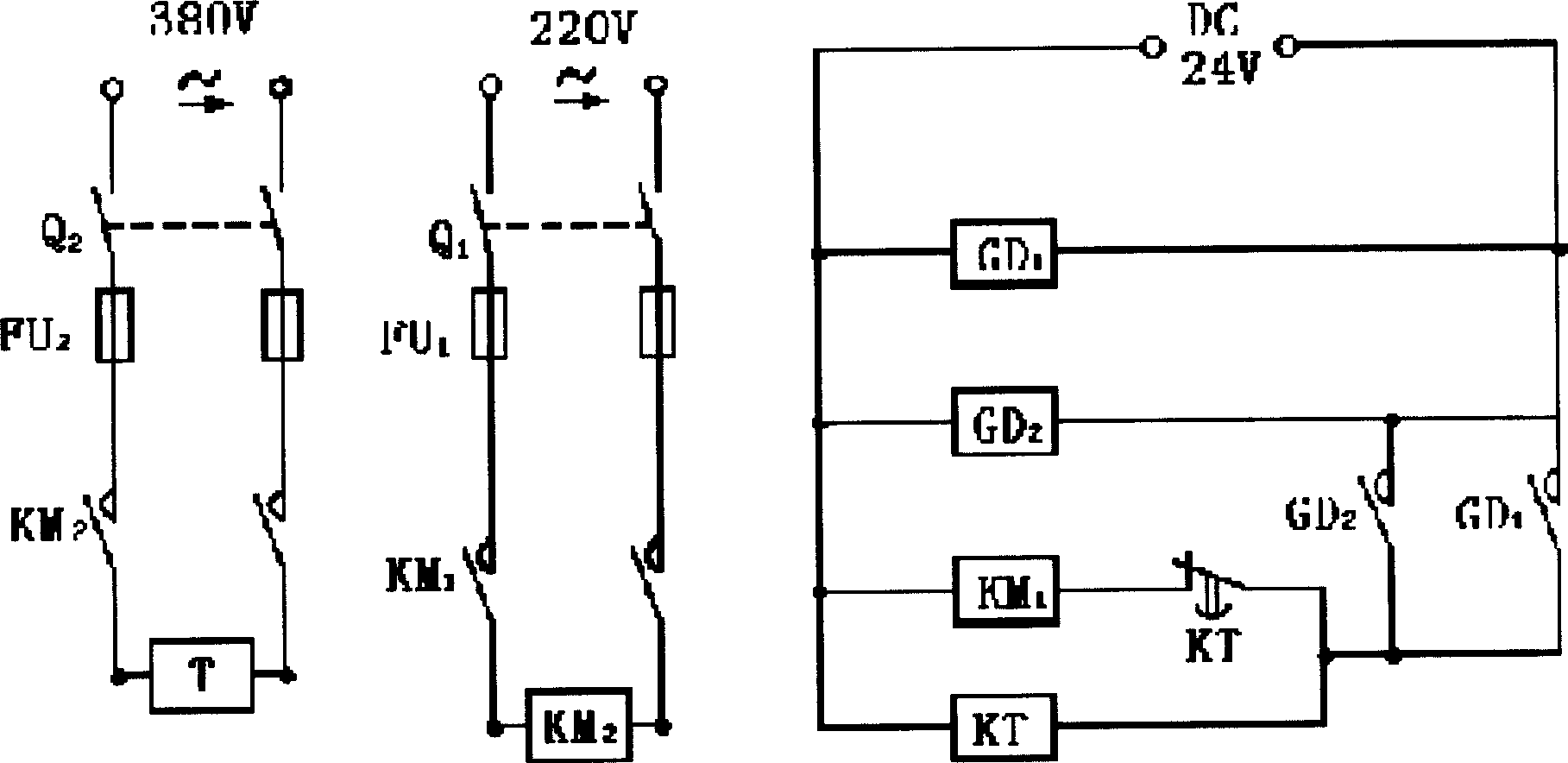

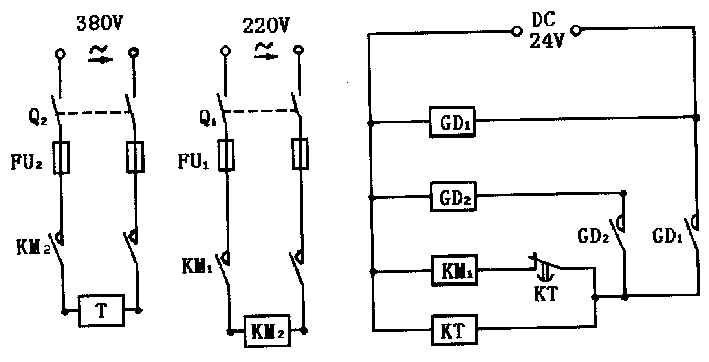

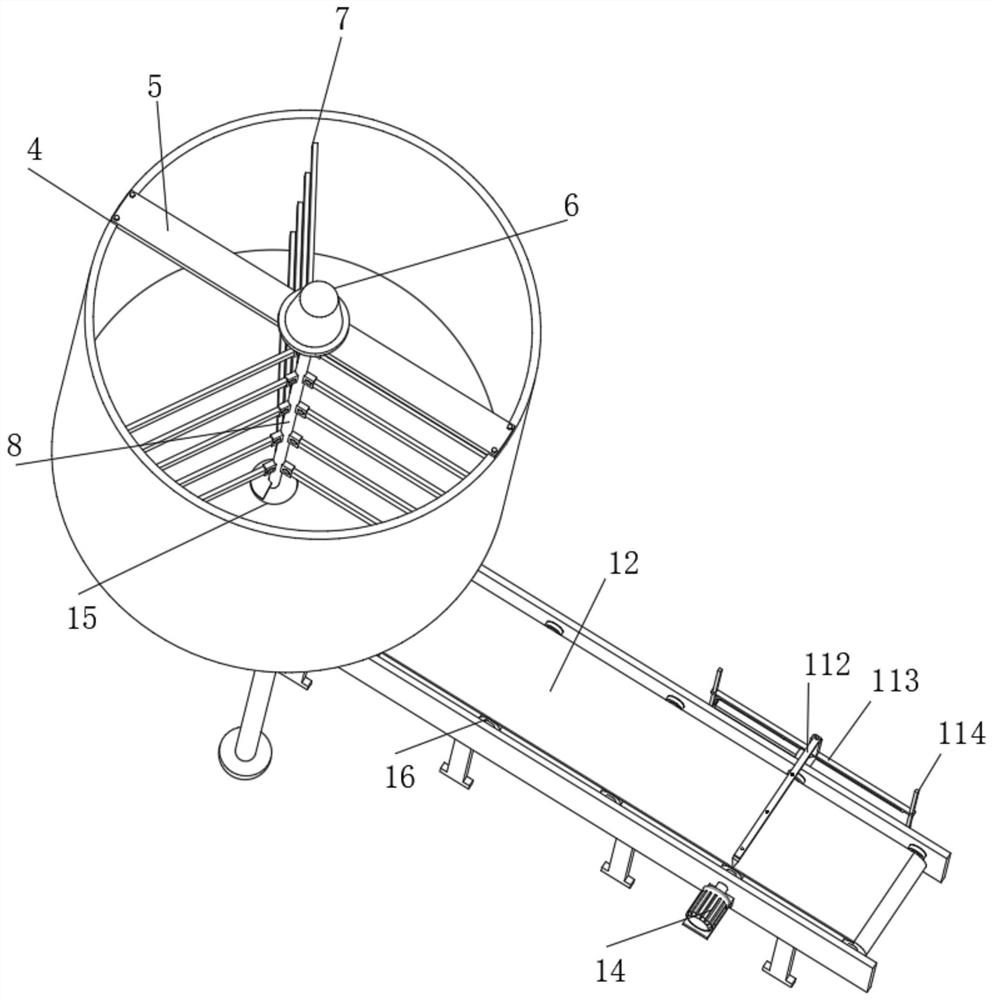

Precise automatic cut-off machine

The invention discloses a precise automatic cut-off machine. The precise automatic cut-off machine comprises a stand, a power roller and a guide roller are arranged at two transverse sides of the stand, the power roller and guide roller are provided with a transmission mechanism, the transmission mechanism is provided with a feeding mechanism, and the transmission mechanism is capable of driving the feeding mechanism to rotate circularly; the feeding mechanism comprises a plurality of fixed troughs, the fixed troughs are bowl-shaped, an interval remains between adjacent fixed troughs, and the upper openings of the fixed troughs form discharge holes; a rotating cutter mechanism is arranged at the horizontal right side of the stand, the rotating cutter mechanism is provided with a longitudinal cutter roller, the cutter roller is arranged above the power roller, the cutter roller is provided with a plurality of cutter blades, and the cutter blades are capable of correspondingly entering the intervals between the fixed troughs; a power mechanism is arranged at the longitudinal rear side of the stand, and the power mechanism can drive the power roller and cutter roller to rotate. The precise automatic cut-off machine is high in cutting efficiency, capable of well realizing the precise material cut and convenient to regulate the cutting length; the honest material and waste material are automatically divided after cutting, the labor force is saved, and the production cost is lowered.

Owner:聊城市博斯麦新材料科技有限公司

Cable protective sleeve and lead clamp thereof

InactiveCN101527432AImprove fire performanceEnvironmentally friendlyElectrical apparatusEngineeringPlastic film

The invention relates to a cable protective sleeve used for families, offices and engineering and a lead clamp thereof. The lead clamp belongs to an auxiliary component and the cable protective sleeve belongs to a main component; the cable protective sleeve is made of a plastic sheet coil pipe, the longitudinal edges of two sides of the plastic sheet coil pipe are superimposed from inside to outside so as to form a cylinder; horizontal I-shaped groove holes are uniformly distributed on the cylinder wall, and the length of the horizontal I-shaped groove holes is 2 / 3 to 4 / 5 of the width of a plastic sheet; the lead clamp consists of a pair of plastic clamping pieces and an elastic fastener which can clamp the clamping pieces; the upper parts of the clamping pieces are respectively provided with a lead shuttle end, and the middle parts are respectively provided with a binding wire hole; a pivoted device is arranged below the binding wire hole; and a handle is arranged at the lower part of the pivoted device. The cable protective sleeve has the advantages of adopting environment-friendly and regenerative material, having elegant and beautiful appearance, being suitable for indoor and outdoor to use, having simple structure and various specifications and being capable of effectively protecting the cable.

Owner:许福章

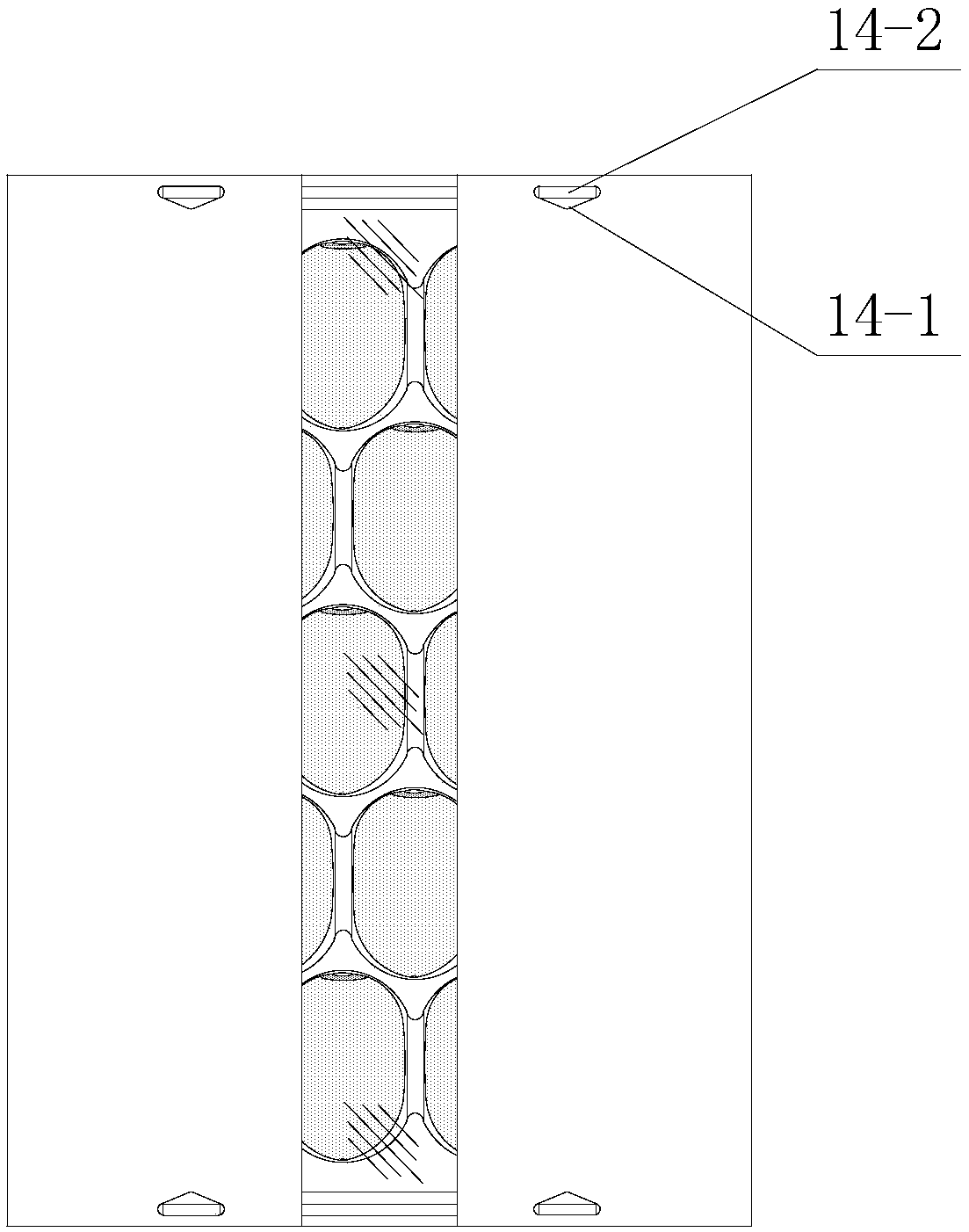

Continuous braided winding pultrusion high-strength composite glass steel tube and preparation method thereof

PendingCN111497290AHigh strengthImprove heat resistanceMetal working apparatusTubular articlesGlass fiberSolid wall

The invention discloses a continuous braided winding pultrusion high-strength composite glass steel tube and a preparation method thereof. The composite glass steel tube is composed of fiber and thermosetting resin; the fiber is divided into five layers, the inner layer and the outer layer are braised by glass fiber, the secondary interlayer is wound by the glass fiber, and the glass fiber is longitudinally paved on the interlayer; the five layers of fiber and the thermosetting resin are composite to form a compact and complete pipeline structure; the pipeline structure is a circular solid-wall pipe; the thermosetting resin is unsaturated polyester resin; and the glass fiber is alkali-free glass fiber. The glass steel tube is composed of the fiber and the thermosetting resin, the five layers of fiber and the thermosetting resin are composite to form the compact and complete pipeline structure, and the strength of the glass steel tube can be improved; and meanwhile, a molecular structure of the thermosetting resin is in a body type, the thermosetting resin comprises most condensation resin, and the thermosetting resin can increase the heat resistance and the performance of difficultdeformation by being pressed of the glass steel tube.

Owner:ZHEJIANG FEILONG PIPE

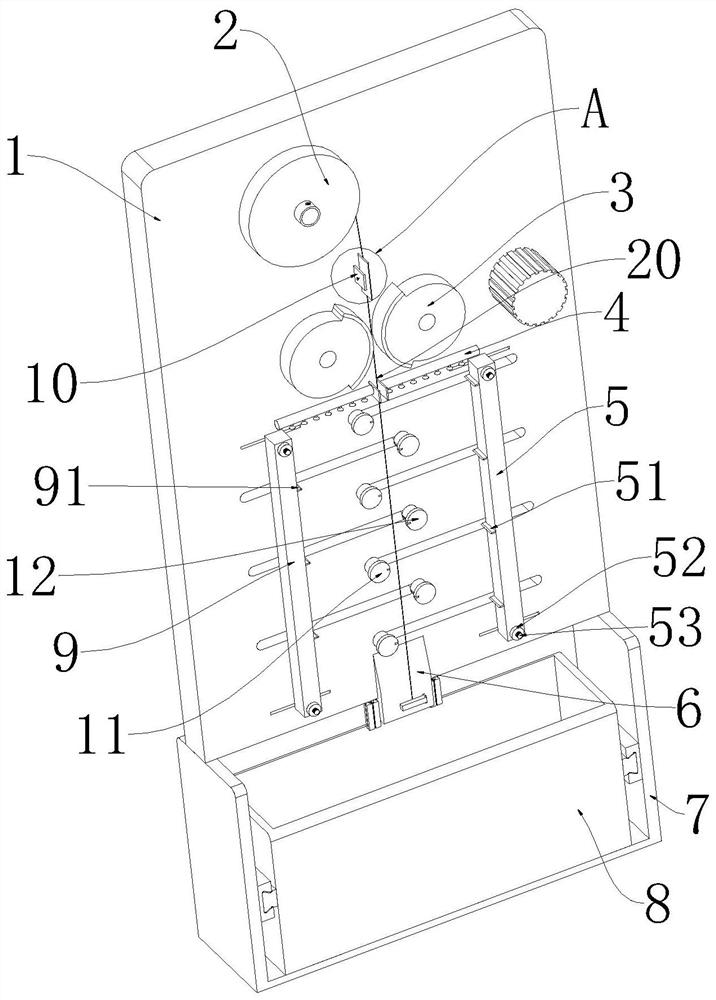

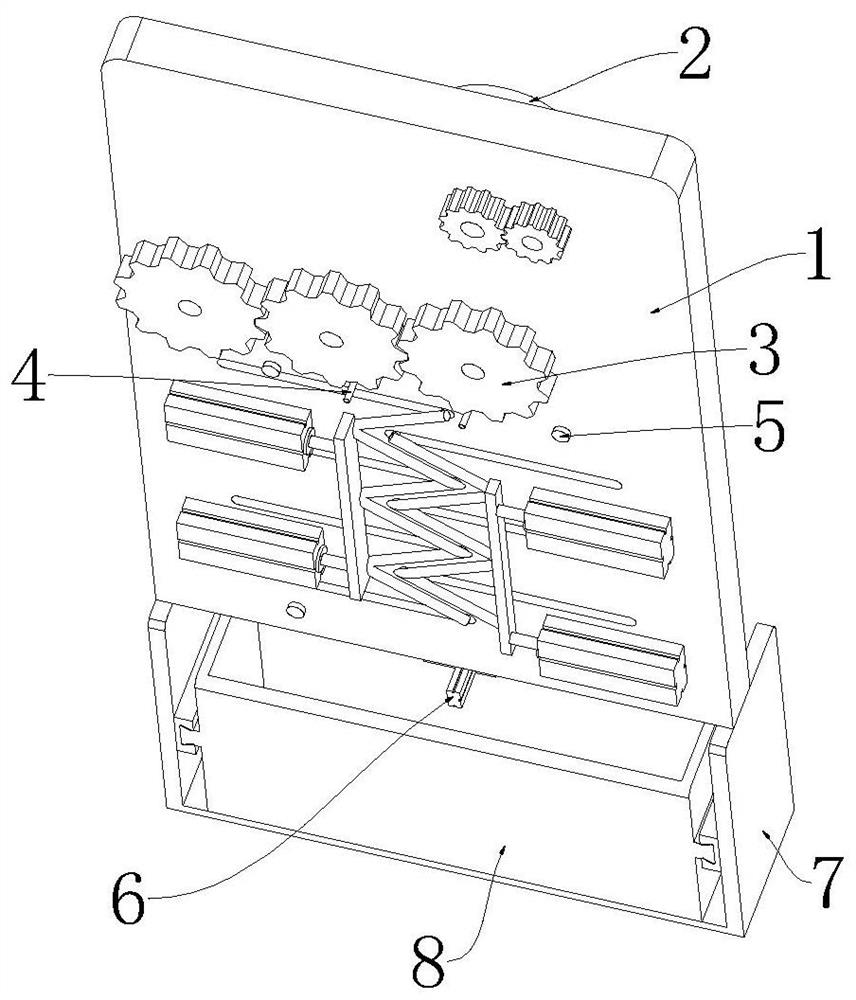

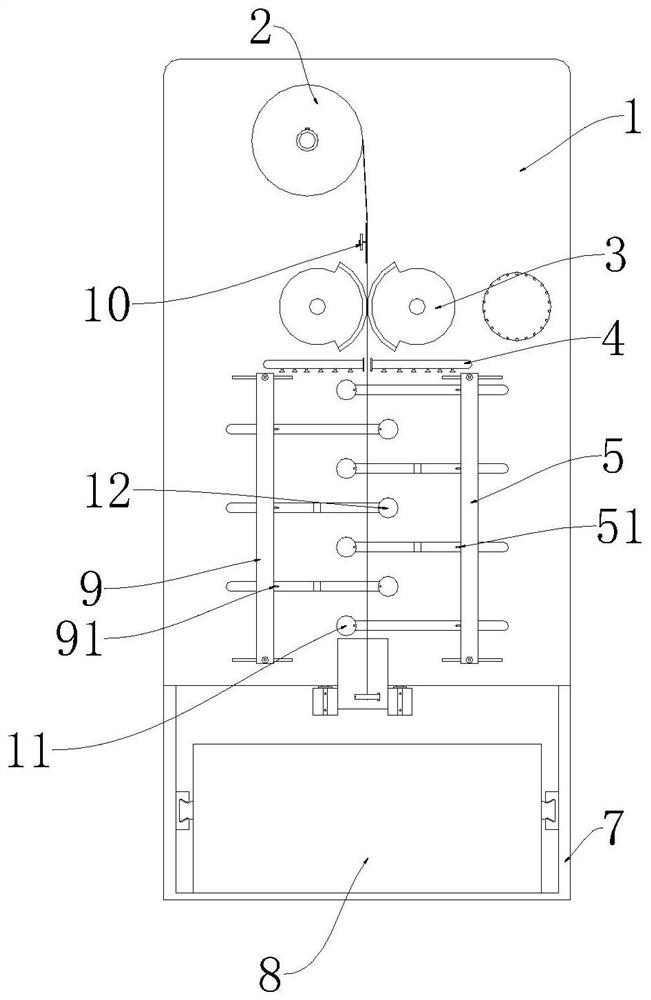

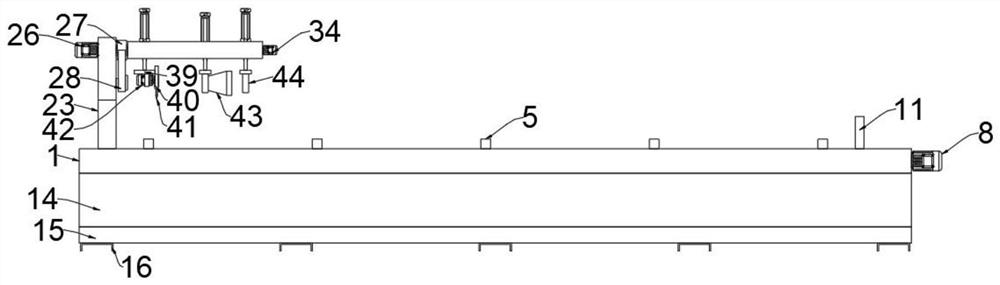

Automatic twisting equipment for cable

The invention discloses automatic twisting equipment for a cable. The automatic twisting equipment comprises a strip-shaped bearing pedestal, the upper surface of the strip-shaped bearing pedestal is fixedly connected with a strip-shaped work box, the strip-shaped work box is internally provided with an automatic twisting mechanism, the strip-shaped bearing pedestal is internally provided with a stretching discharging mechanism, and a moving mechanism is arranged on the lower surface of the strip-shaped bearing pedestal. The automatic twisting equipment for the cable has the beneficial effects that operation is relatively convenient, the automatic twisting equipment can adapt to different diameters of cables to carry out twisting, fixed length cutting is controlled conveniently, collection is convenient, flow line production is facilitated, the labor intensity is relieved, and the working efficiency is improved.

Owner:江苏敬业泵业有限公司

Mechanical arm grabbing type automatic fruit packaging equipment and method

InactiveCN109573206AImprove packaging efficiencyReduce packaging costsPackaging fruits/vegetablesManipulatorEngineering

The invention discloses mechanical arm grabbing type automatic fruit packaging equipment and method. According to the equipment, a box body conveyor is sequentially provided with a thin film tractionslitting station, a fruit filling station, a film covering station and a cover closing station. A thin film traction slitting device is arranged at the thin film traction slitting station. A plastic suction tray bin is arranged on one side of the thin film traction slitting station and provided with a suction cup type mechanical arm. A fruit conveyor is arranged on one side of the fruit filling station. A fruit grabbing device is arranged at the fruit filling station. A film covering and packaging device is arranged at the film covering station. A cover closing and packaging device is arrangedat the cover closing station. The method sequentially comprises the following steps that a thin film is cut through the thin film traction slitting device; the thin film is flatly laid on the surfaceof a paper box; fruit filling is carried out through the fruit grabbing device; the thin film is overturned into the paper box through the film covering and packaging device, so that the thin film iscovered on the surface of fruits; and a closing cover is folded, pressed and closed through the cover closing and packaging device until the closing cover is fastened with the box body. By means of the mechanical arm grabbing type automatic fruit packaging equipment and method, online automatic fruit packaging can be realized, manual operation is replaced, and the packaging cost is reduced.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

Machining cutting device facilitating positioned cutting

InactiveCN107717090AAvoid shakingConvenience to workMaintainance and safety accessoriesShearing machine accessoriesEngineeringMachining

The invention discloses a cutting device for machining, which is convenient for positioning and cutting. It comprises a support frame, a protective shell is fixedly installed on the top of the support frame, a first chute is opened on the upper surface of the support frame, and a cutting device is arranged on the upper side of the support frame. plate, the first chute is slidably connected to the cutting board through the first sliding block provided in it, the inner wall of the top plate of the protective shell is fixedly installed with a first electric push rod, and the bottom of the first electric push rod is fixedly installed with a connecting seat, connecting Both ends of the seat are fixedly installed with connecting plates. In the present invention, the distance between two adjacent fixed plates can be adjusted during processing by arranging a second electric push rod, two motors installed in opposite directions, and fixed plates distributed at equal distances, and simultaneously through a plurality of fixed plates By fixing the material, it is convenient to control two motors to work at the same time, and it is convenient for people to cut to a fixed length, which can avoid the shaking of the material, and the use is more flexible and convenient.

Owner:无锡宝威焊割设备有限公司

Polypropylene rope fixed-length cutting-off processing device

ActiveCN111761624AImprove work efficiencyEasy to cut to lengthMetal working apparatusStructural engineeringPolypropylene

The invention relates to the technical field of rope processing, in particular to a polypropylene rope fixed-length cutting-off processing device. The device comprises a rope pulling assembly, a clamping assembly, second electric cylinders, second supporting columns, first electric cylinders, first blades and second blades. A polypropylene rope is pulled downwards through the rope pulling assembly, when the polypropylene rope moves downwards to a proper position, the bottom of the polypropylene rope is fixed through the clamping assembly, the second electric cylinders work to drive the secondsupporting columns to move leftwards, the first electric cylinders work to drive first supporting columns to move rightwards, the polypropylene rope is pulled to move downwards through the moving second supporting columns and the moving first supporting columns, the second supporting columns and the first supporting columns support the polypropylene rope, and when the first supporting columns andthe second supporting columns move to make contact with the first blades and the second blades respectively, a plurality of fixed-length polypropylene rope segments are cut at a time, so that the working efficiency is improved; and manual work is replaced with a machine, so that time and labor are saved.

Owner:兰陵县瑞生绳业有限公司

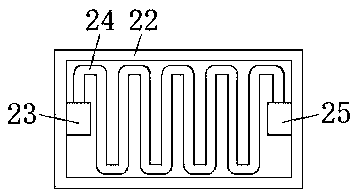

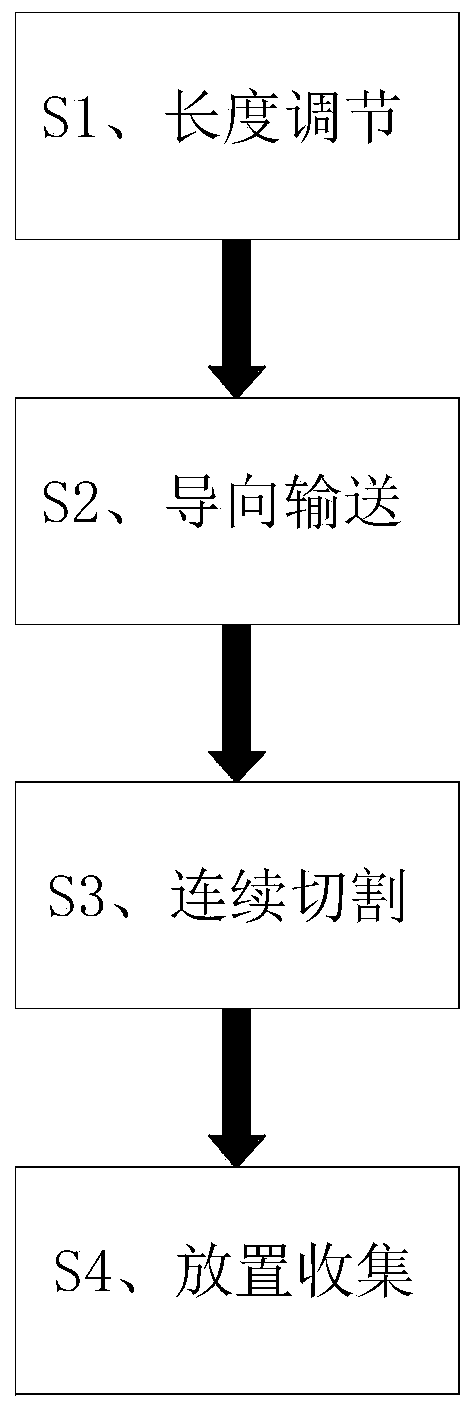

Rubber waterstop manufacturing and processing technology

ActiveCN111531595AEasy to cut to lengthSmooth cutMetal working apparatusElectric machineryDrive motor

The invention relates to a rubber waterstop manufacturing and processing technology. The rubber waterstop manufacturing and processing technology is mainly completed by matching a rubber strip manufacturing automatic cutting machine. The rubber strip manufacturing automatic cutting machine comprises a machine table, a reset translation mechanism, a contraposition guide plate assembly, a cutting mechanism, a fixed-length adjusting mechanism and an intermittent rotation clamping die mechanism, and the intermittent rotation clamping die mechanism comprises a motor fixing seat, a driving motor, atoggle disc, a grooved pulley, a rotation support, a rotation part and a clamping die. The cutting machine provided by the invention meets the requirement of fixed-length cutting of rubber waterstopswith different lengths, can realize continuous automatic cutting and automatic overturning unloading, avoids the trouble and inconvenience of traditional manual cutting, has regular cuts and greatly improves the cutting efficiency.

Owner:JINGJIANG YONGHE POLYMOLECULAR TECH

Metal band as inlay for trim strips or sealing strips

ActiveUS20060185132A1Easy to cut to lengthReduce energy inputSnap fastenersLayered productsEngineeringElectrical and Electronics engineering

A metal band inlay for trim strips or sealing strips of flexible material that is bent to form a section. The metal band includes a plurality of edge slots in the longitudinal direction, which are guided inwardly from an edge of the metal band transversely to the longitudinal direction. The edge slots are wedge shaped. Central slots run to a tip toward their respective two ends and are arranged between the sequential edge slots. The central slots extend transversely to the longitudinal direction, but do not extend up to the edge. To simplify the cutting, the metal band further includes throughcuts that extend transversely to the longitudinal direction of the metal band, that correspond to at least some of the central slots and that extend from at least one edge of the metal band in the direction toward the tip of the respective central slot disposed opposite to the edge.

Owner:BFC FAHRZEUGTEILE GMBH

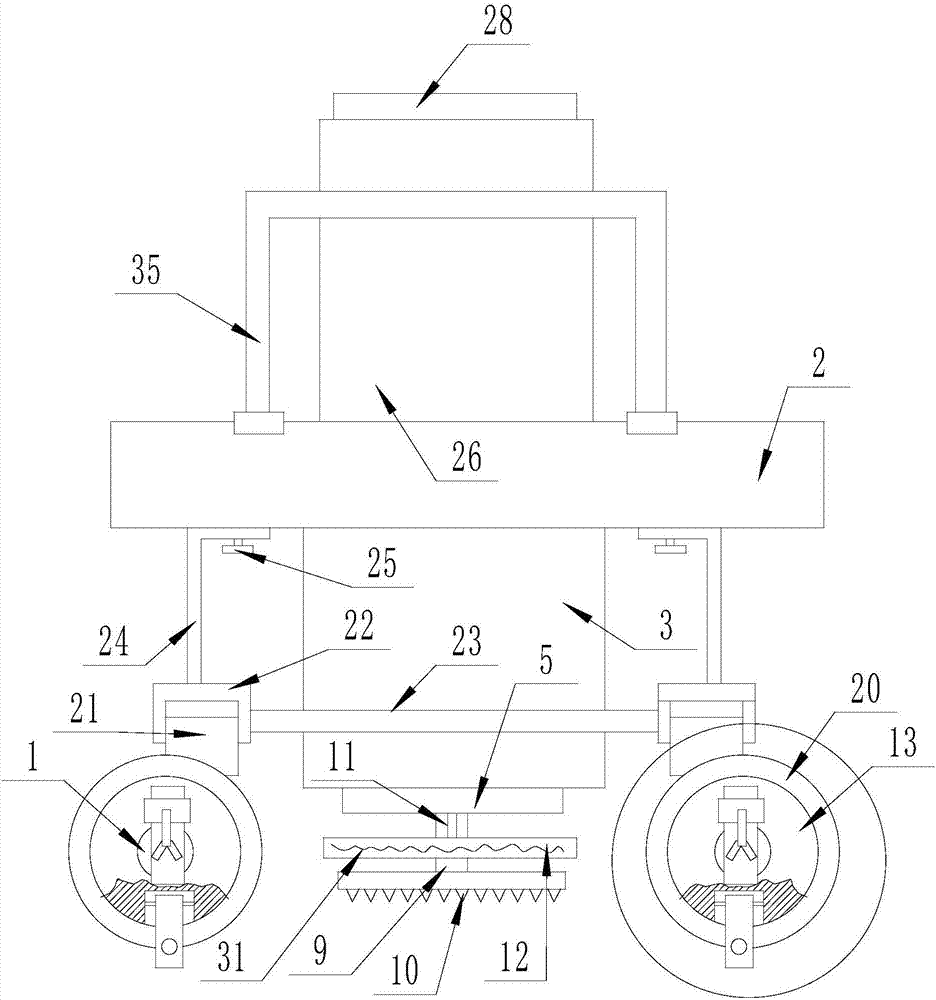

Automatic connector pin inserting machine capable of conducting fixed-length cutting on pins

InactiveCN112108590AEasy to cut to lengthAvoid the trouble of sorting and loadingContact member assembly/disassemblyMetal working apparatusEngineeringMachine

The invention discloses an automatic connector pin inserting machine capable of conducting fixed-length cutting on pins. The automatic connector pin inserting machine specifically comprises a workbench, a conveying belt, a pin seat, a functional seat and a fixed-length mechanism, wherein a conveying frame is arranged at one side of the top of the workbench; the conveying belt is arranged in the conveying frame; a mounting plate is fixed into the middle of one side of the top of the conveying frame; and a photoelectric sensor is fixed to the top end of one side, close to the conveying belt, ofthe mounting plate. According to the automatic connector pin inserting machine capable of conducting fixed-length cutting on the pins, through the arrangement of the fixed-length mechanism, fixed-length cutting can be conducted on the pins conveniently, the cutting length is controllable, the applicability is higher, and compared with a traditional mode that the pins are cut into proper lengths firstly and then inserted, cutting and pin inserting are completed at a time, the pins are conveyed one by one, the trouble that the pins need to be sorted and fed in the subsequent inserting process isavoided, the machining steps are simplified, and the production efficiency is higher.

Owner:高晓云

Tubular feed-through capacitor fixed-length cutting device with surface scratch detection function

InactiveCN112170964AAvoid offsetPrecise cuttingShearing machine accessoriesHydraulic cylinderCapacitance

The invention discloses a tubular feed-through capacitor fixed-length cutting device with a surface scratch detection function. The tubular feed-through capacitor fixed-length cutting device specifically comprises a workbench, a capacitor to be cut, driving wheels, a detection bin and a sliding base, wherein a portal frame is installed in the middle of the top of the workbench, and a hydraulic cylinder is installed at the top end of the portal frame; and a mounting plate is arranged at the top end in portal frame, and the output end of the hydraulic cylinder penetrates through the top end of the portal frame to be connected with the mounting plate. According to the tubular feed-through capacitor fixed-length cutting device with the surface scratch detection function, the driving wheels arearranged, the outer side of each driving wheel is sleeved with a rubber sleeve through a spring, the rubber sleeves can clamp and limit the capacitor to be cut and can rotate along with the driving wheels, so that clamping and feeding are synchronously carried out, automatic feeding is achieved, a worker does not need to push the capacitor manually, a clamped clamp does not need to be loosened during feeding every time, and the machining efficiency is higher.

Owner:东莞市固德智能科技有限公司

Equipment for automatic labelling for surfaces of metal doors and windows

The invention discloses equipment for automatic labelling for surfaces of metal doors and windows. The equipment comprises a group of drawing frames; a strip-shaped carrying plate is arranged above the group of drawing frames; a moving labelling mechanism is arranged on the lower surface of the strip-shaped carrying plate; a clamping and fixing mechanism is arranged on the lower surface of each drawing frame; an automatic moving mechanism is arranged between the upper surfaces of the group of drawing frames and the moving labelling mechanism; and an adhesive tape storage mechanism is arranged on the upper surface of the strip-shaped carrying plate. The equipment has the beneficial effects as follows: the equipment is relatively simple to operate, the adhesion length can be adjusted according to the lengths of frames of the doors and windows, the labor intensity can be reduced, beautiful adhesion can be realized, the working efficiency can be improved, waste of adhesive tapes can be reduced, fixed-length cutting of the adhesive tapes can be realized relatively conveniently, and the equipment is convenient to carry.

Owner:斯卡特(北京)铝业集团有限公司

Knife assembly sheet disintegrator

The invention relates to disc sheet combined knife crusher and belongs to crop crushing machine technical field which comprise frame shell, cutting tool and main axle, feeding device and reducing machine drive device. The main axle is fixed at two ends of frame shell and driven by motor out of the frame shell. The cutting tool is composed of a set of disc sheet type moving knife, a set of fixed knife and a set of cutting knife. The disc sheet type moving knife is mounted on main axle in parallel. Several cutting knives mounted on main axle are positioned between the adjacent disc sheet type moving knives. The fixed knife is fixed in parallel at corresponding frame shell separating from disc sheet moving knife and cutting knife. The disc sheet type moving knife and fixed knife is zigzag mounted which endow the device high crushing efficiency and adjustable cutting length. The inventive crusher has simple structure, and is conveniently charged or discharged. The inventive crusher is suitable for cutting and crushing of the rice straw, wheat straw, corn stalk, cotton stalk or fruit tree branch etc.

Owner:范建华

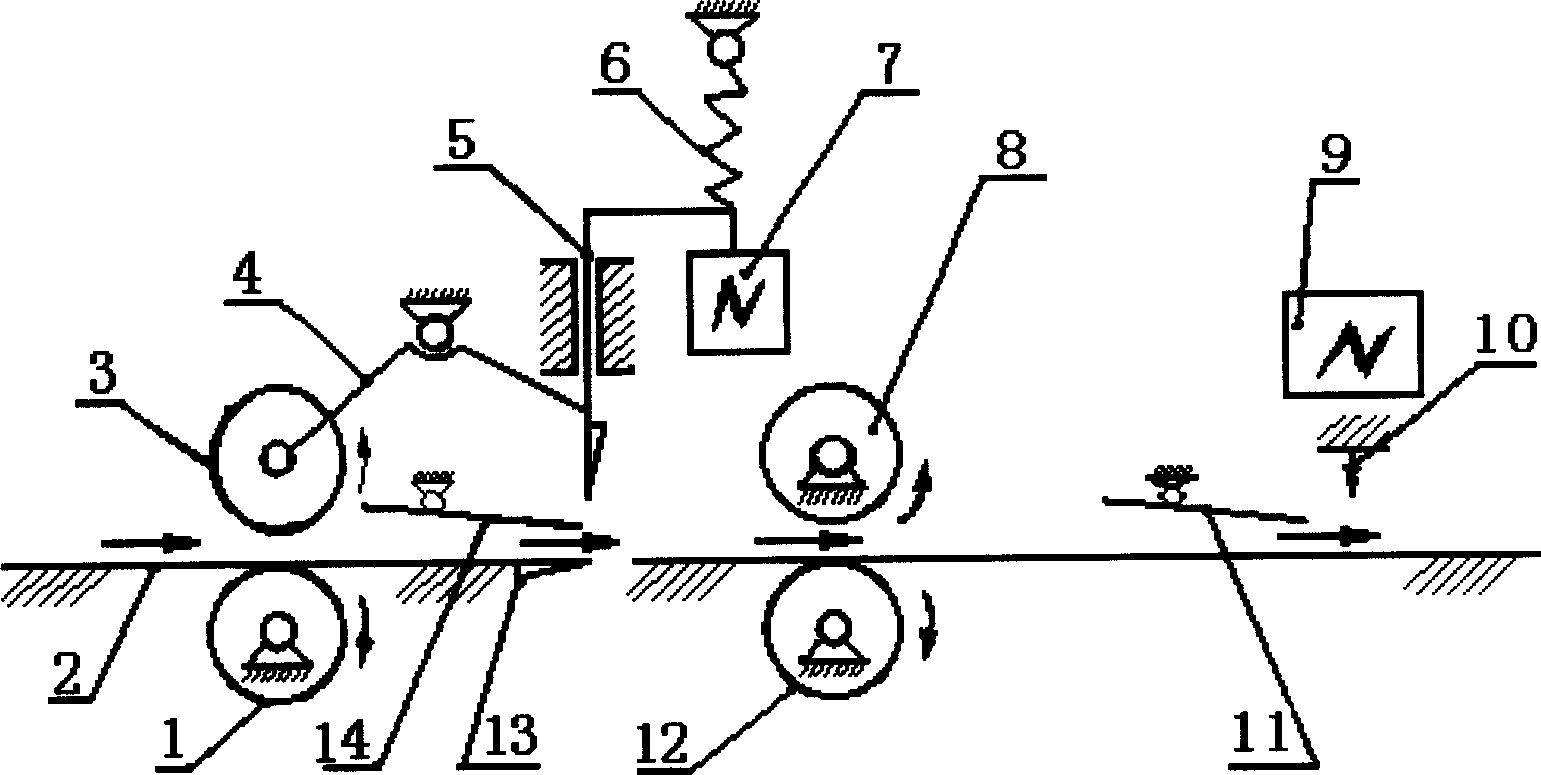

Flexible fixed length automatic disconnecting device for sheet material

InactiveCN1565816AEasy to adjustEasy to cut to lengthVeneer manufactureElectrical controlElectric control

A sheet flexible length control and automatic cutting device for log rotary cutting production characterized in that it comprises a front guiding mechanism, a pre-pressing mechanism, a cutting mechanism and a rear feeding mechanism and electric control mechanism, wherein the front guiding mechanism, the pre-pressing mechanism, the cutting mechanism and the rear feeding mechanism sequently connect to the sheet moving guide rail on the frame, and the electromagnet movable armature of the electric control mechanism connects to the cutting knife movable blade of the cutting mechanism, photoelectric switch is fixed on the discharge part of the cutting mechanism, the power mechanism connects to the front guiding mechanism and rear feeding mechanism by transmission unit. The invented device can precisely control the sheet length and quickly cut.

Owner:姚运仕 +1

Pipe cutting device

A pipe cutting device comprises a cutter assembly, an installation plate of the cutter assembly, a working platform, an air cylinder, an air cylinder frame, a foot switch, a fixed pressing block, an enhanced safety component and a size control device; the cutter assembly comprises a fixed bottom plate, a cutting knife fixing plate and a cutting knife fixing plate return spring; a hose supporting base group and a cutting knife fixing plate connecting base are fixedly arranged at front and back ends of the fixed bottom plate respectively, and the hose supporting base group comprises a main supporting base and a protective supporting base; the rear end of the cutting knife fixing plate is hinged to the cutting knife fixing plate connecting base; a piston head of the air cylinder abuts against the cutting knife fixing plate; the size control device comprises a size control stopping block; the fixed bottom plate is placed inside a positioning hole formed in the installation plate of the cutter assembly and is pressed against and fixed on the working platform through the fixed pressing block; the enhanced safety component is fixedly arranged on the right side of the hose supporting base group and comprises front and back enhanced safety blocks, highest points of the front and back enhanced safety blocks are higher than the highest position of a tip of a cutting knife, and the distance between the front and back enhanced safety blocks is 10-20mm larger than the diameter of a hose.

Owner:NINGBO SOOJEE SANITARY WARE

Pipeline cutting bracket for water conservancy project construction

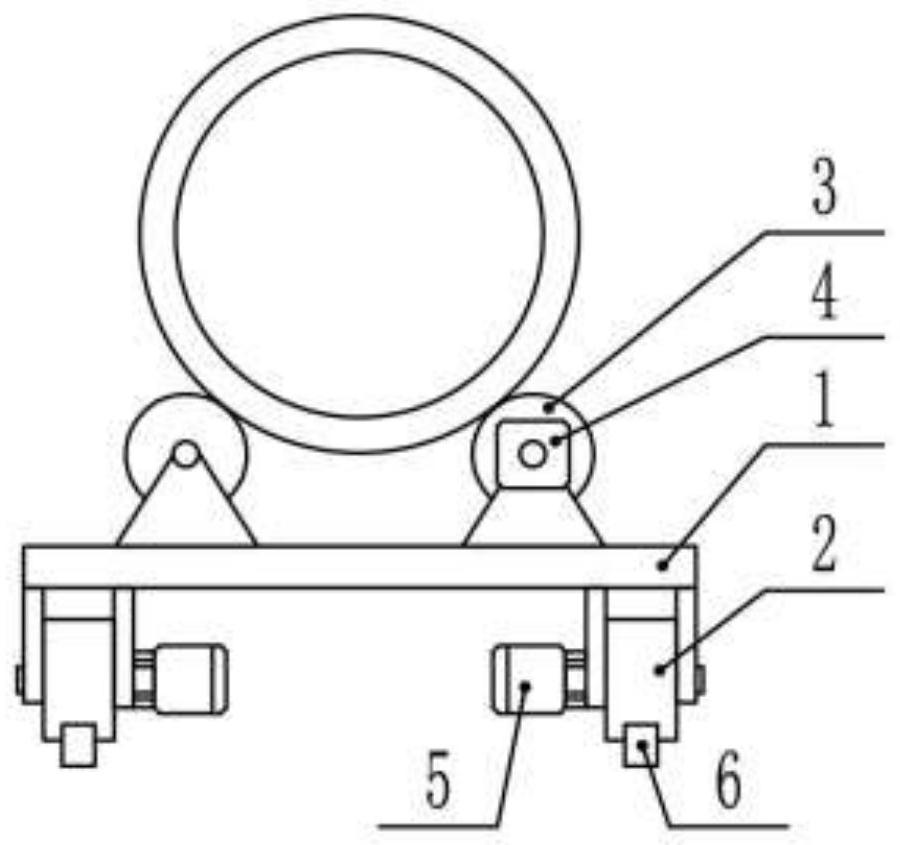

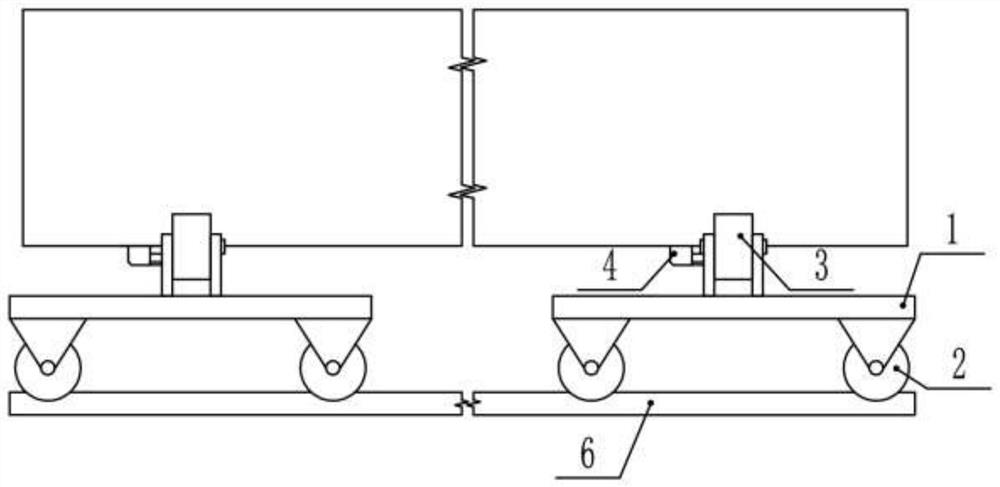

InactiveCN111790938ATurn aroundImprove verticalityFeeding apparatusTube shearing machinesControl systemControl engineering

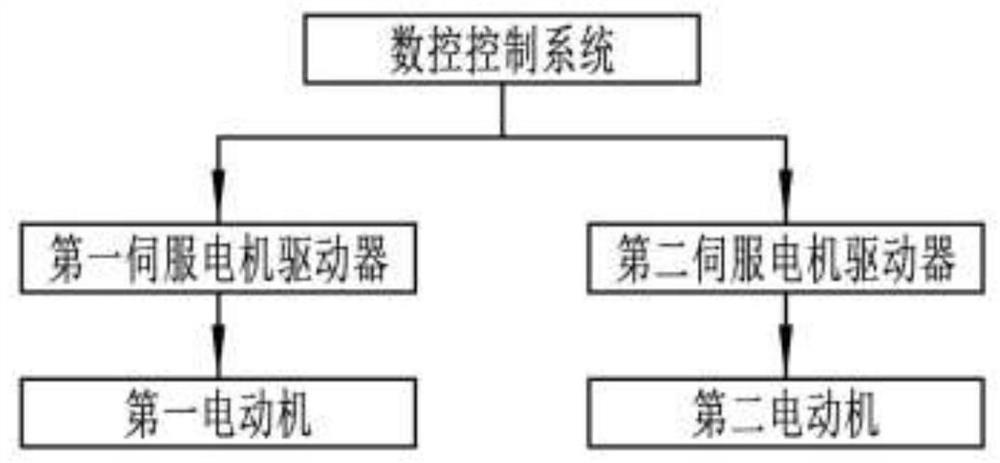

The invention discloses a pipeline cutting bracket for water conservancy project construction, and relates to the technical field of water conservancy project construction equipment. The pipeline cutting bracket comprises tracks and track vehicles, wherein supporting wheels are arranged on the upper surface of each track vehicle, and the supporting wheels are used for supporting a pipeline and enables the pipeline to achieve rotation along the axis of the pipeline. The track vehicles move along the tracks, and translation movement of the pipeline is achieved. The pipeline cutting bracket is further provided with first electric motors and second electric motors, and rotation and translation of the pipeline are driven by the electric motors, so that manpower is saved; and the first electricmotors and the second electric motors are all servo motors, and the servo motors have a locking function and can lock the pipeline at a designated location. The pipeline cutting bracket is further provided with first servo motor drivers, second servo motor drivers and a numerical control system. Notch curves including intersecting lines of complex pipelines can be achieved.

Owner:崔俊峰

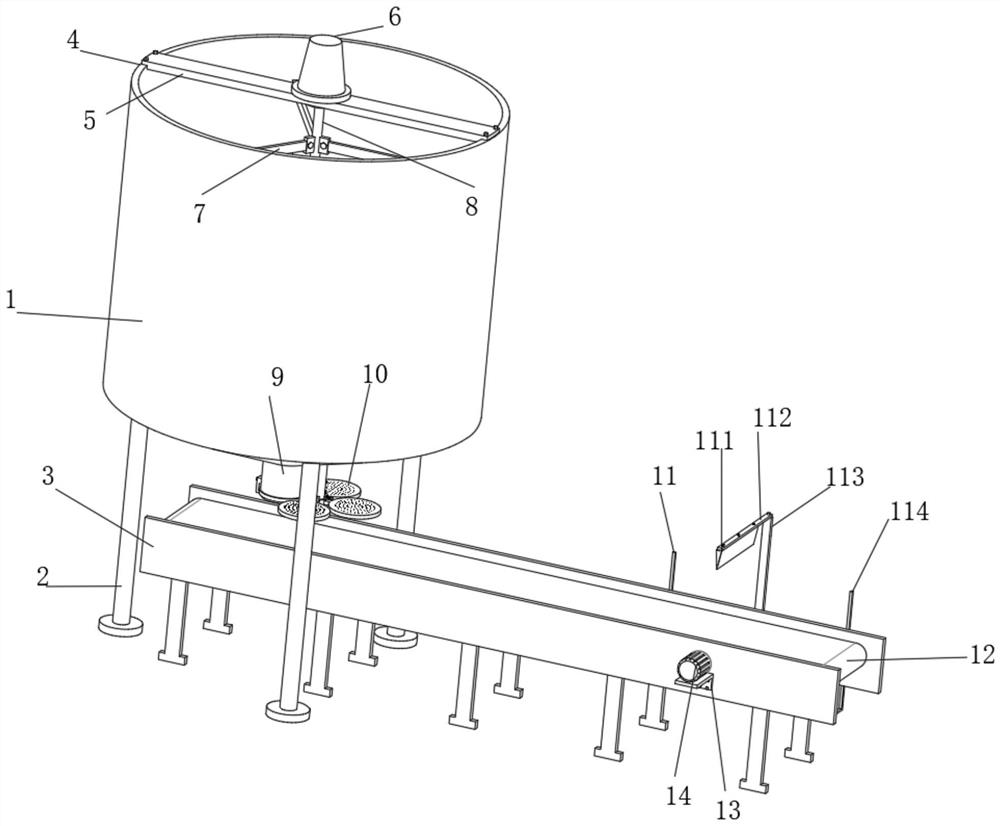

Processing technology and process equipment for kudzu root noodle

ActiveCN112493267ARelieve pressureExtended service lifeMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsProcess equipmentStraight tube

The invention relates to a processing technology and process equipment for kudzu root noodle in the technical field of making noodle. The process equipment includes a stirring tank; the stirring tankis provided with supporting legs and a stirring structure; the stirring tank is provided with a straight pipe; the straight pipe is provided with a noodle extrusion structure; the noodle extrusion structure includes a C-shaped plate, a straight rod, round plates, through holes, springs, straight blocks, a supporting bearing, inserting rods, horizontal blocks, bumps and a supporting round ring; thestraight pipe is provided with a supporting rack; the supporting rack is provided with transfer rollers; the transfer rollers are provided with a conveyor belt; the front ends of one set of the transfer rollers are connected to a second driving motor; and the rear ends of the transfer rollers connected with the second driving motor are connected to a cutting structure for cutting noodle. Throughthe process equipment, the noodle with different thicknesses can be produced through adjustment according to actual production needs, so that the actual production can be realized, and the practicability of the equipment can be enhanced.

Owner:FUZHOU CHANGSHENG FOOD

Bamboo pole cutting device for bamboo furniture production and cutting method thereof

ActiveCN113334512ASolve the problem of cutting efficiencyAutomate operationWood splittingMulti-purpose machinesElectric machineryStructural engineering

The invention discloses a bamboo pole cutting device for bamboo furniture production and a cutting method of the bamboo pole cutting device, relates to the related field of bamboo furniture production, and aims to solve the problems that according to an existing automatic bamboo pole cutting device, a pushing structure pushes a bamboo pole to move in the direction of a cutting structure, so that length cutting is completed, however, the pushing structure needs to be reset after pushing and cutting one bamboo pole each time, at the moment, the cutting structure is in an idle state, and the bamboo pole cutting efficiency is affected. A driving unit is arranged on one side of the upper end of the cutting table top and comprises a supporting stand column, the supporting stand column is fixed to the cutting table top, a middle stand column is fixedly connected to the middle of the upper end of the supporting stand column, a second driving motor is installed at the upper end of the outer side of the middle stand column, a communicating column is arranged at the upper end of the inner side of the middle stand column, an output shaft of the second driving motor penetrates through the middle stand column to be fixed to the communicating column, the lower end of the outer side of the communicating column is fixedly connected with a rotating fan-shaped disc, and a limiting mutual groove is formed in the rotating fan-shaped disc.

Owner:ANHUI SHUCHENG HUAZHU IND

Cable with scales

InactiveCN103021544AClear length displayEasy to cut to lengthInsulated cablesInsulated conductorsEngineering

The invention discloses a cable with scales. The cable comprises an outer sheath and a cable core, wherein a length scale device is arranged at the surface of the outer sheath and comprises the length scales and cut-off marks at the surface of the outer sheath. The cable with the scales disclosed by the invention can facilitate construction and the selection on cut-off length in this manner.

Owner:茅凯

High-strength ultra-micro glass fiber cotton reinforced HDPE double-wall corrugated pipe

InactiveCN111016116AImprove rigidityStrong creep resistanceMetal working apparatusGlass fiberPolymer science

The invention discloses a high-strength ultra-micro glass fiber cotton reinforced HDPE double-wall corrugated pipe. The HDPE double-wall corrugated pipe is prepared through the following steps that 1,100-120 parts by weight of HDPE resin, 40-60 parts by weight of wood flour, 1-3 parts by weight of a titanate coupling agent, 7-9 parts by weight of ethylene propylene diene monomer and 30-45 parts by weight of ultramicro glass fiber cotton are weighed; and 2, the wood flour is dried through two-stage combined pulse airflow. One side of the corrugated pipe makes contact with a second L-shaped rod, one end of the pipe is inserted into the clamping mechanism; meanwhile, three cylinders II are driven; a piston rod pushes a lifting block to ascend upwards in a sliding groove. A rubber base is pushed to move through a second rotating block, a connecting rod and a first rotating block, under cooperation of a rocker, the corrugated pipe is clamped through a rubber belt, the connecting rod is sleeved with a spring, through the arrangement of the spring, in the moving process of the rubber base, good buffering performance is achieved, and the corrugated pipe is prevented from being damaged.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com