Cable protective sleeve and lead clamp thereof

A technology for protective sleeves and cables, applied in electrical components and other directions, can solve the problems of accelerated cable aging, increased safety hazards, and complicated operations, and achieves the effect of reducing friction and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

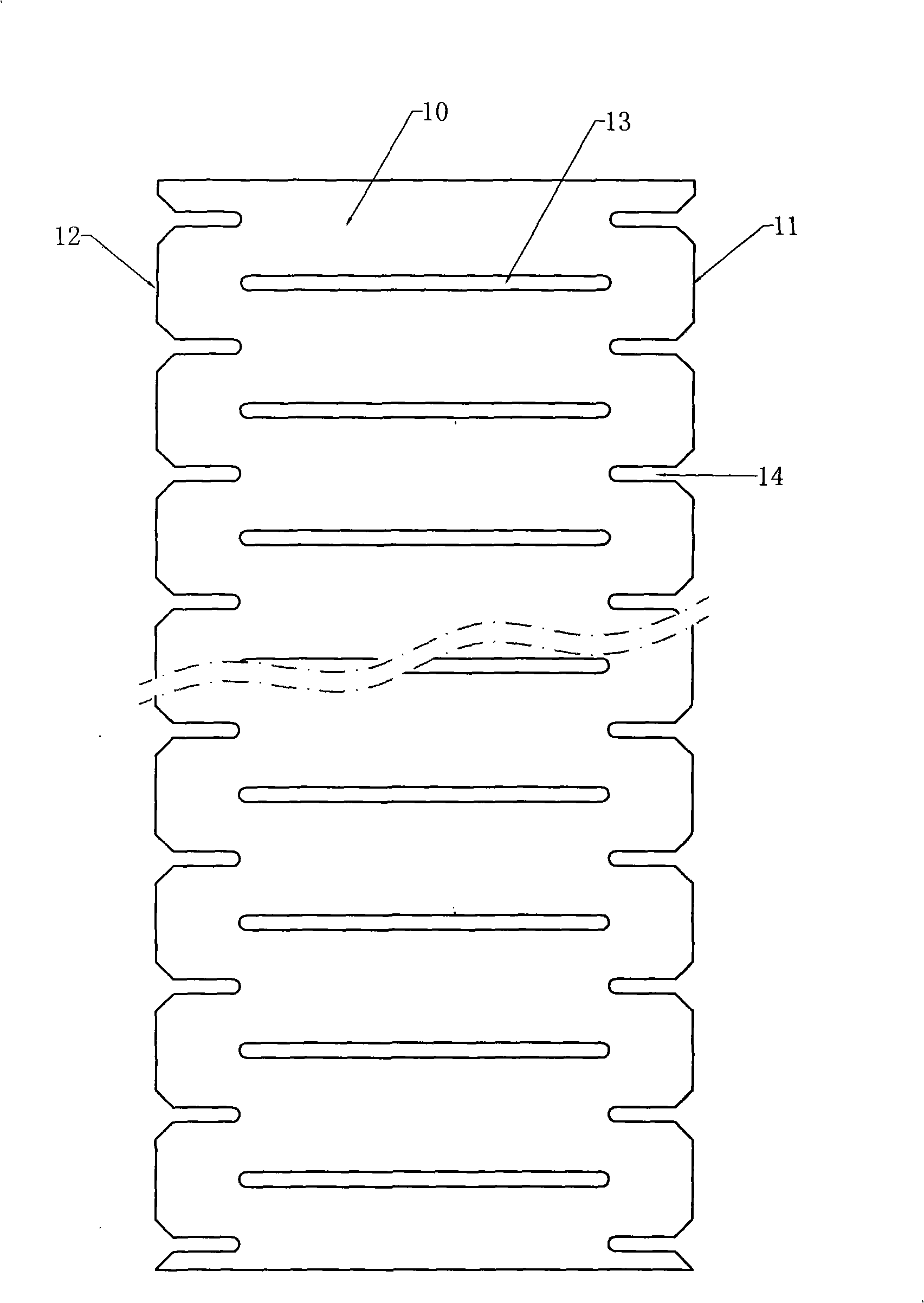

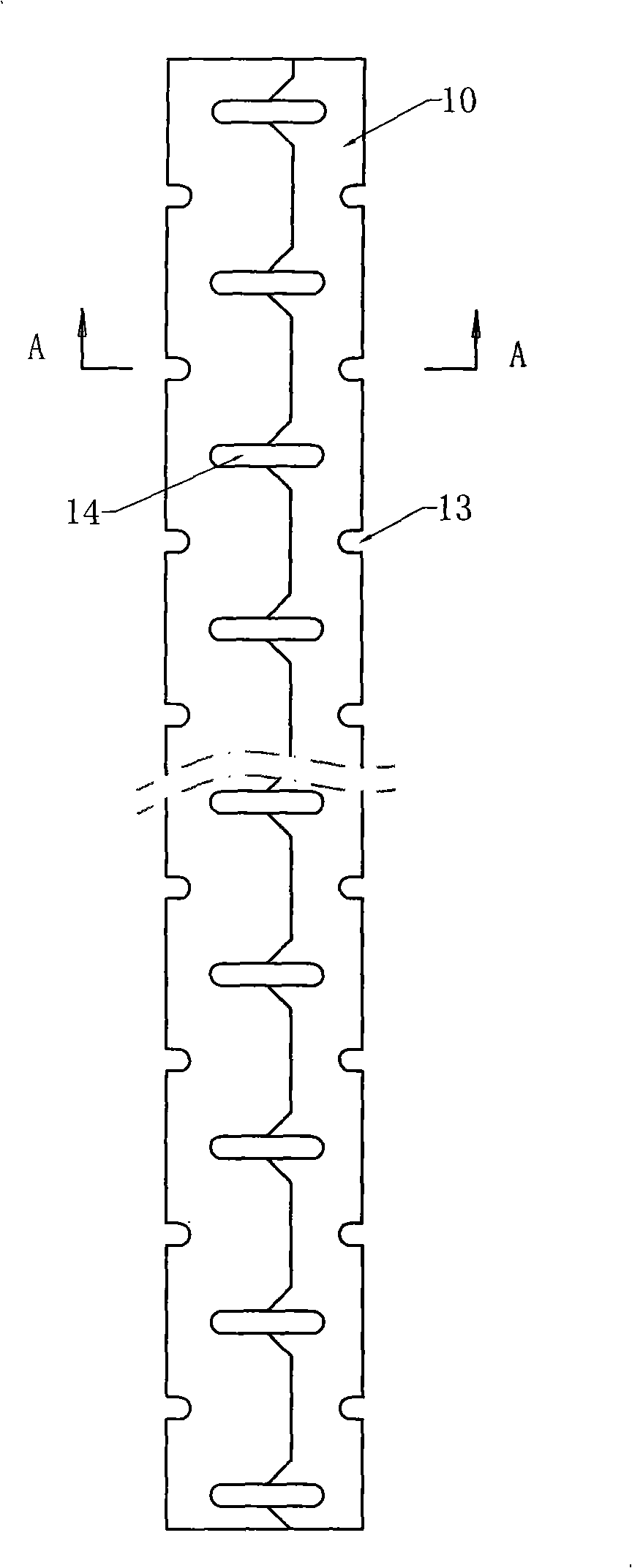

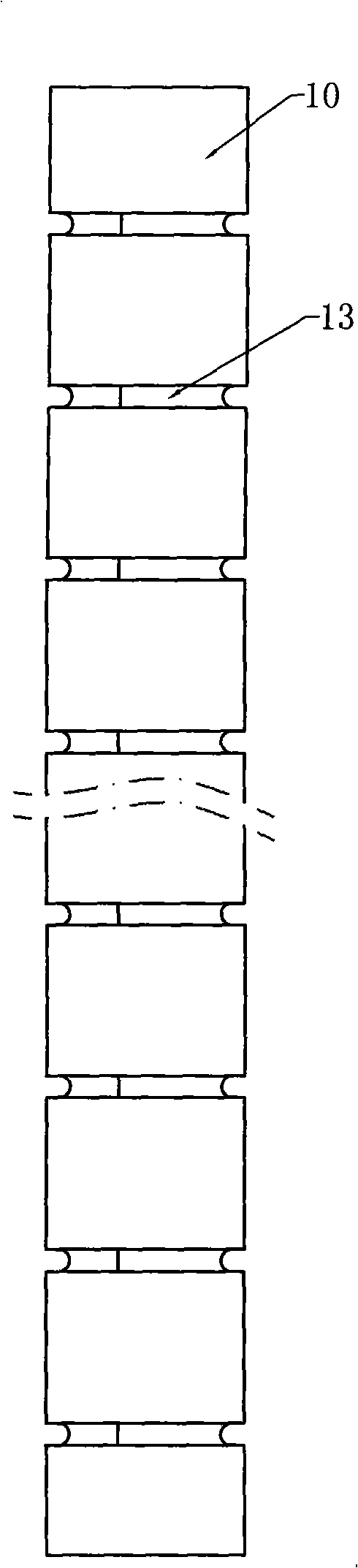

[0032] Embodiment 1. Cable protective sleeve.

[0033] refer to Figure 1-Figure 4 , the cable protective sleeve is made of plastic sheet 10 curled, and the longitudinal edges 11 and 12 on both sides are laminated inside and outside to form a cross-section of The inner and outer overlapping width of the two longitudinal edges 11 and 12 accounts for 1 / 5 of the width of the plastic sheet. On the cylinder wall, there are evenly distributed horizontal "one"-shaped slots 13, and the "one"-shaped The length of the slot accounts for 3 / 4 of the width of the plastic sheet. On the longitudinal edges of the two sides, there are respectively symmetrically and evenly distributed transverse notches 14, and the notches and the slots are arranged alternately.

[0034] Its production method is: 1) adopt PE material to produce sheet, then use shearing equipment to punch out "one" shaped slot 13 and notch 14, such as figure 1 Shown; 2) Use coiled tube equipment to figure 1 The sheet materi...

Embodiment 2

[0035] Embodiment 2, lead clip.

[0036] refer to Figure 5-Figure 9 , the lead clip is composed of a left clip 220 , a right clip 210 and an elastic buckle 30 . The upper part 221 of the left clip and the upper part 211 of the right clip constitute the thread shuttle head; the concave cavity 222 of the left clip and the concave cavity 212 of the right clip constitute a circular binding hole; the bottom 224 of the left clip and the right clip The lower part 214 of the bottom constitutes the handle of the lead clip, and the handle can be controlled to open or close the lead clip; the elastic buckle 30 is installed on the left clip through the through hole 225 on the left clip handle and the through hole 215 on the right clip handle. On the sheet 220 and the right clip 210, the ends of the elastic buckle 30 are fastened respectively on the rib 226 of the left clip and the rib 216 of the right clip, the groove 223 on the left clip and the rib on the right clip 213 constitutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com