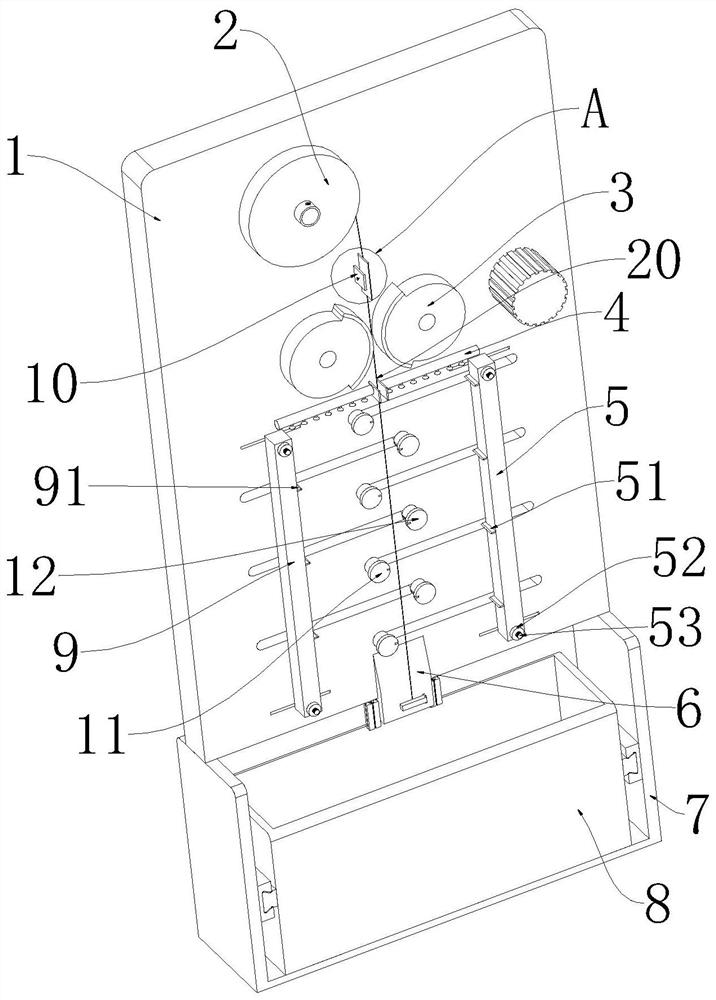

Polypropylene rope fixed-length cutting-off processing device

A technology of cutting processing and polypropylene fiber, which is applied in the field of polypropylene rope fixed-length cutting processing device, can solve the problems of time-wasting efficiency, easy confusion, inconvenience, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

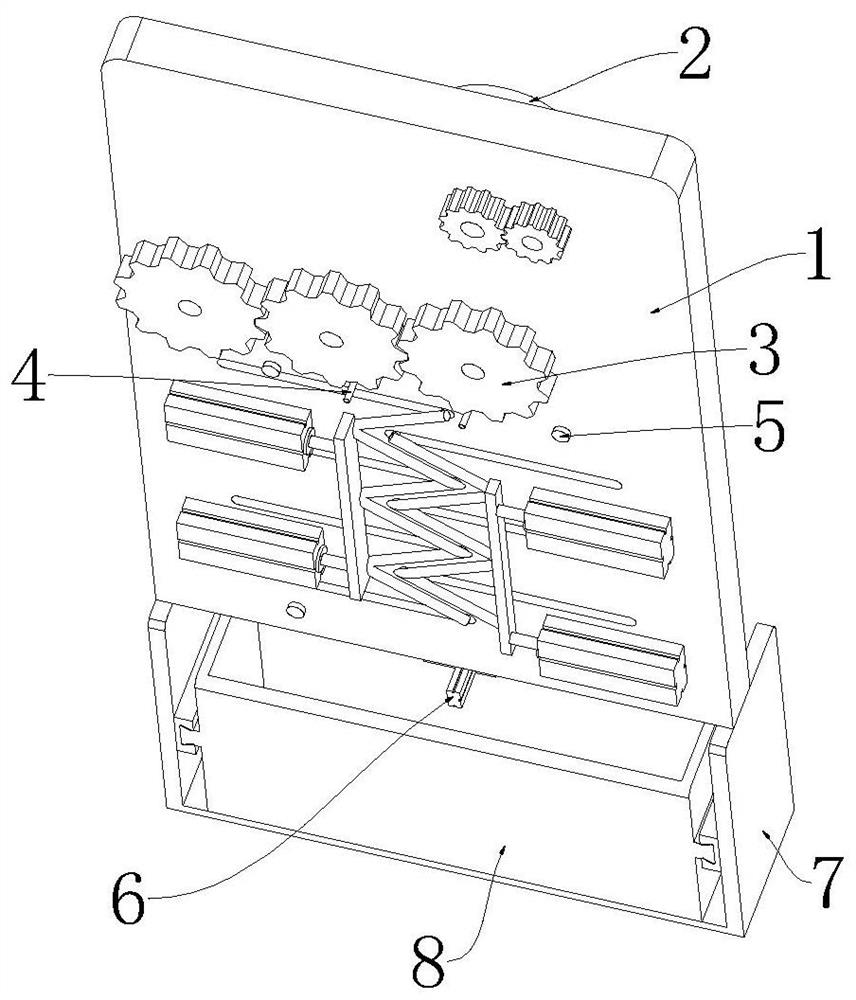

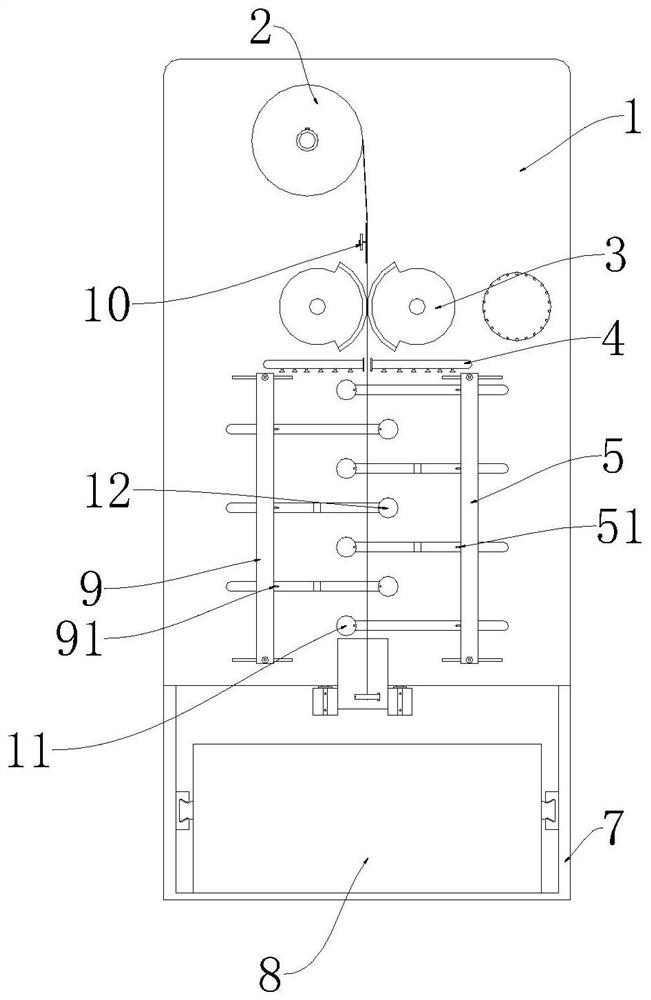

Method used

Image

Examples

specific Embodiment approach

[0042] The specific embodiment: connect the power supply of the fourth electric cylinder 66, when the piston rod of the fourth electric cylinder 66 is moved forward, the rear end of the stay cord 65 moves forward, because the pressing plate 63 and the connecting frame 64 pass through the torsion spring connected, so the pressing plate 63 moves forward under the elastic force of the torsion spring, so that there is a gap between the pressing plate 63 and the movable block 61, so that the lower end of the polypropylene rope 20 can move between the movable block 61 and the pressing plate 63 , start the motor 34 through the switch, the motor 34 works to drive the fourth gear 33 to rotate, thereby driving the two third gears 32 to rotate relative to each other, and then drive the two tension wheels 31 to rotate, so that the polypropylene rope 20 is pulled downward. The rope 20 moves down to a suitable position, and the motor 34 is turned off. At this time, the two tension wheels 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com