Processing technology and process equipment for kudzu root noodle

A processing equipment and noodle technology, which is applied in the kudzu root noodle processing technology and processing equipment field, can solve the problems of inconvenient adjustment of noodles, unfavorable equal length, etc., and achieve the effects of improving practicability, reducing pressure, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

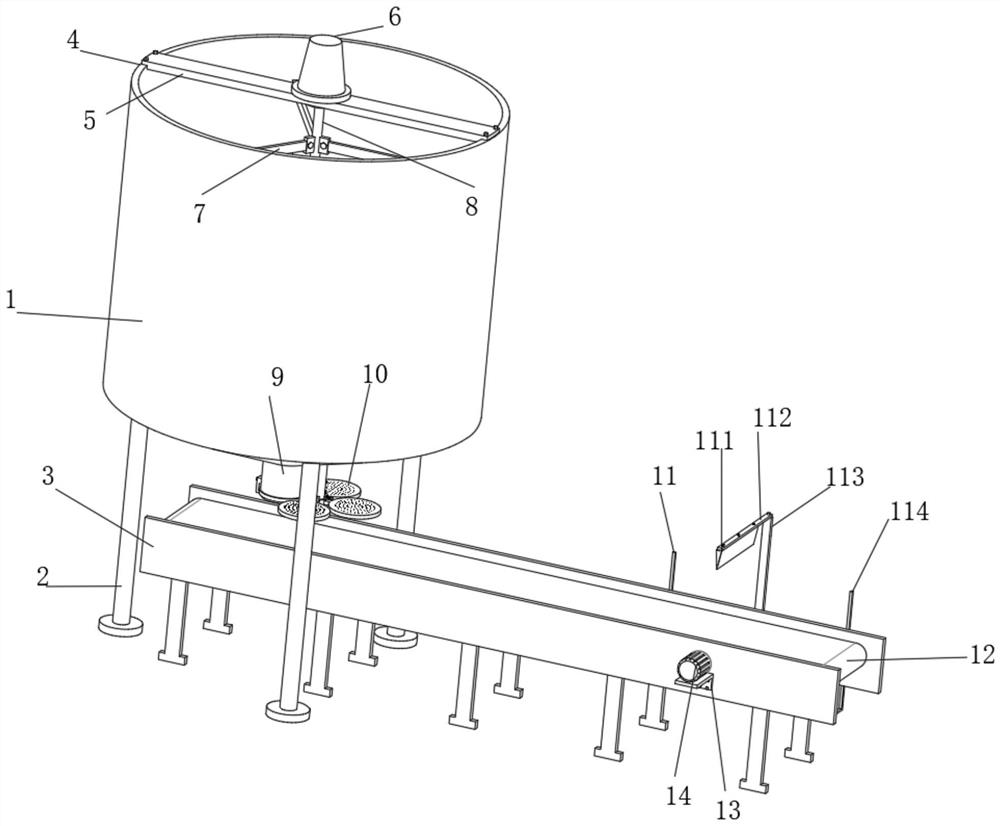

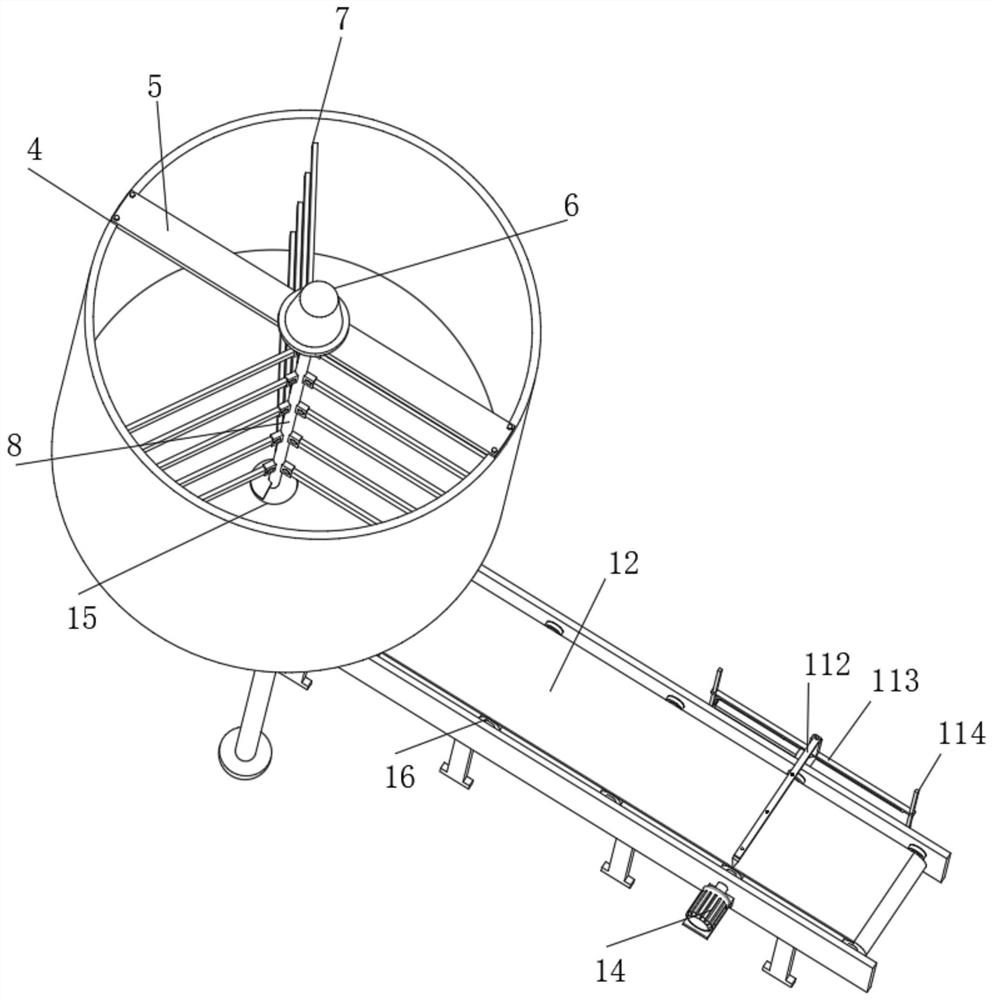

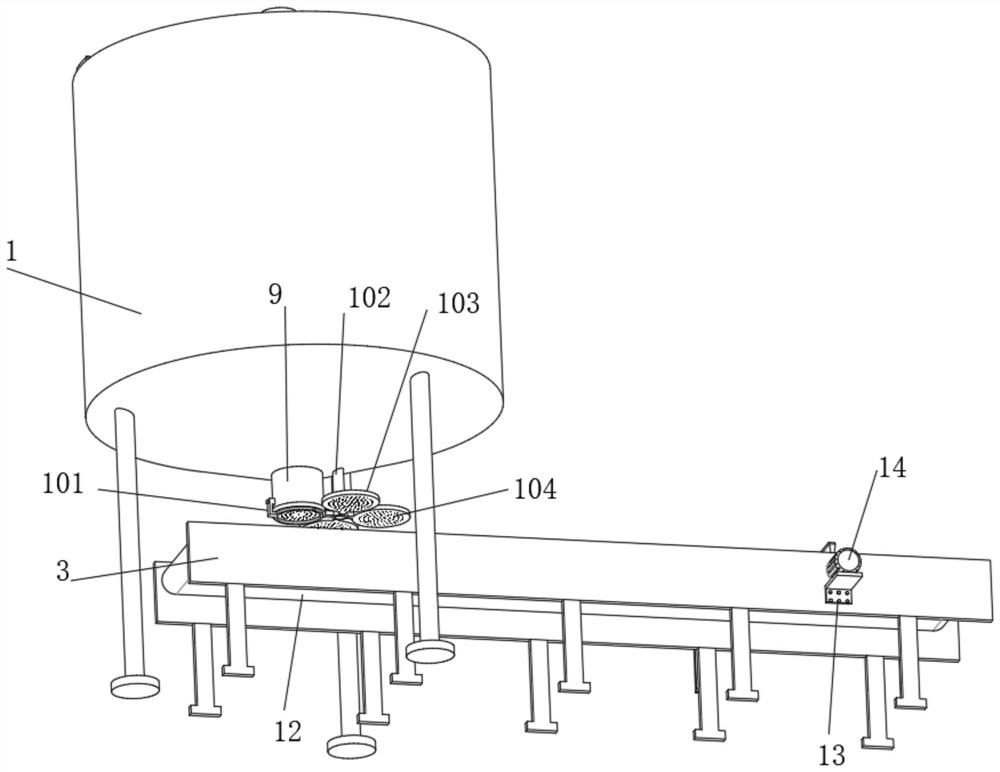

[0045] Such as figure 1 , 2 A kind of kudzu root noodle processing equipment shown in , 5, 9, comprises stirring box 1, supporting leg 2, support frame 3, conveyer belt 12, support plate 13, the second driving motor 14, auger 15 and conveying roller 16, stirring box The bottom of 1 is uniformly and fixedly connected with supporting legs 2 along the circumferential direction, and the top of the mixing box 1 is connected with a stirring structure for stirring, which includes a horizontal plate 5, a first drive motor 6, a stirring plate 7 and a stirring shaft 8. The first driving motor 6 is fixedly installed with a horizontal plate 5, the output end of the first driving motor 6 runs through the bottom of the horizontal plate 5 and is fixedly connected with a stirring shaft 8, and the outer wall of the stirring shaft 8 is uniformly fixedly connected with a stirring shaft 8 along the circumferential direction. The stirring plate 7 is fixedly connected to the bottom of the stirring...

Embodiment 2

[0047] Embodiment 2 is a further improvement to Embodiment 1.

[0048] Such as figure 1 , 3 , a kudzu root noodle processing equipment shown in 4, 7, and 9, comprising a stirring box 1, legs 2, a support frame 3, a conveyor belt 12, a support plate 13, a second drive motor 14, an auger 15 and a conveyor roller 16, The bottom of the mixing box 1 is uniformly fixedly connected with supporting legs 2 along the circumferential direction, and the top of the mixing box 1 is connected with a stirring structure for stirring. The stirring structure includes a horizontal plate 5, a first drive motor 6, a stirring plate 7 and The stirring shaft 8, the first driving motor 6 is fixedly installed with the horizontal plate 5, the output end of the first driving motor 6 runs through the bottom of the horizontal plate 5 and is fixedly connected with the stirring shaft 8, and the outer wall of the stirring shaft 8 is evenly fixed and connected along the circumferential direction. On the stirr...

Embodiment 3

[0050] Embodiment 3 is a further improvement to Embodiment 1.

[0051] Such as figure 1 , 2 , 4, 5, 6, 8, and 10 shown a kind of kudzu root noodle processing equipment, including stirring box 1, support leg 2, support frame 3, conveyor belt 12, support plate 13, second drive motor 14, auger 15 and Conveying roller 16, the bottom of mixing box 1 is evenly fixedly connected with supporting leg 2 along the circumferential direction, and the top of mixing box 1 is connected with stirring structure for stirring, and stirring structure comprises transverse plate 5, first driving motor 6, Stirring plate 7 and stirring shaft 8, the first driving motor 6 is fixedly installed with horizontal plate 5, the output end of first driving motor 6 runs through the bottom of horizontal plate 5 and is fixedly connected with stirring shaft 8, and the outer wall of stirring shaft 8 is along the circumferential direction A stirring plate 7 for stirring is evenly and fixedly connected, an auger 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com