Mechanical arm grabbing type automatic fruit packaging equipment and method

An automatic packaging and manipulator technology, applied in the field of fruit packaging, can solve the problems of low packaging efficiency and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

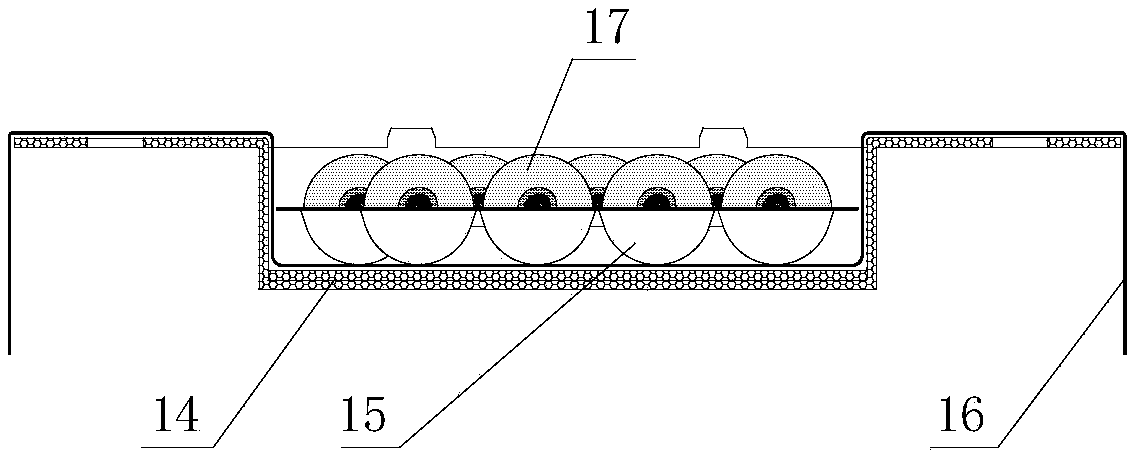

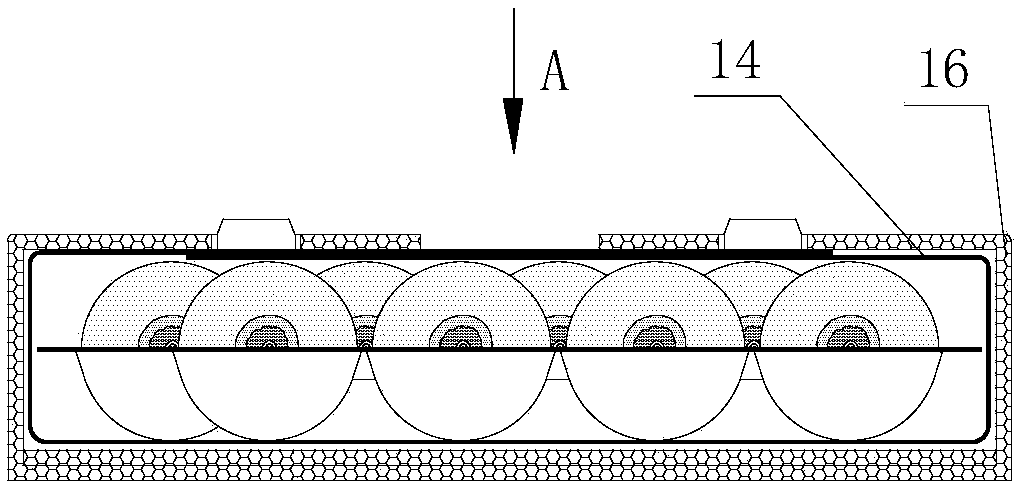

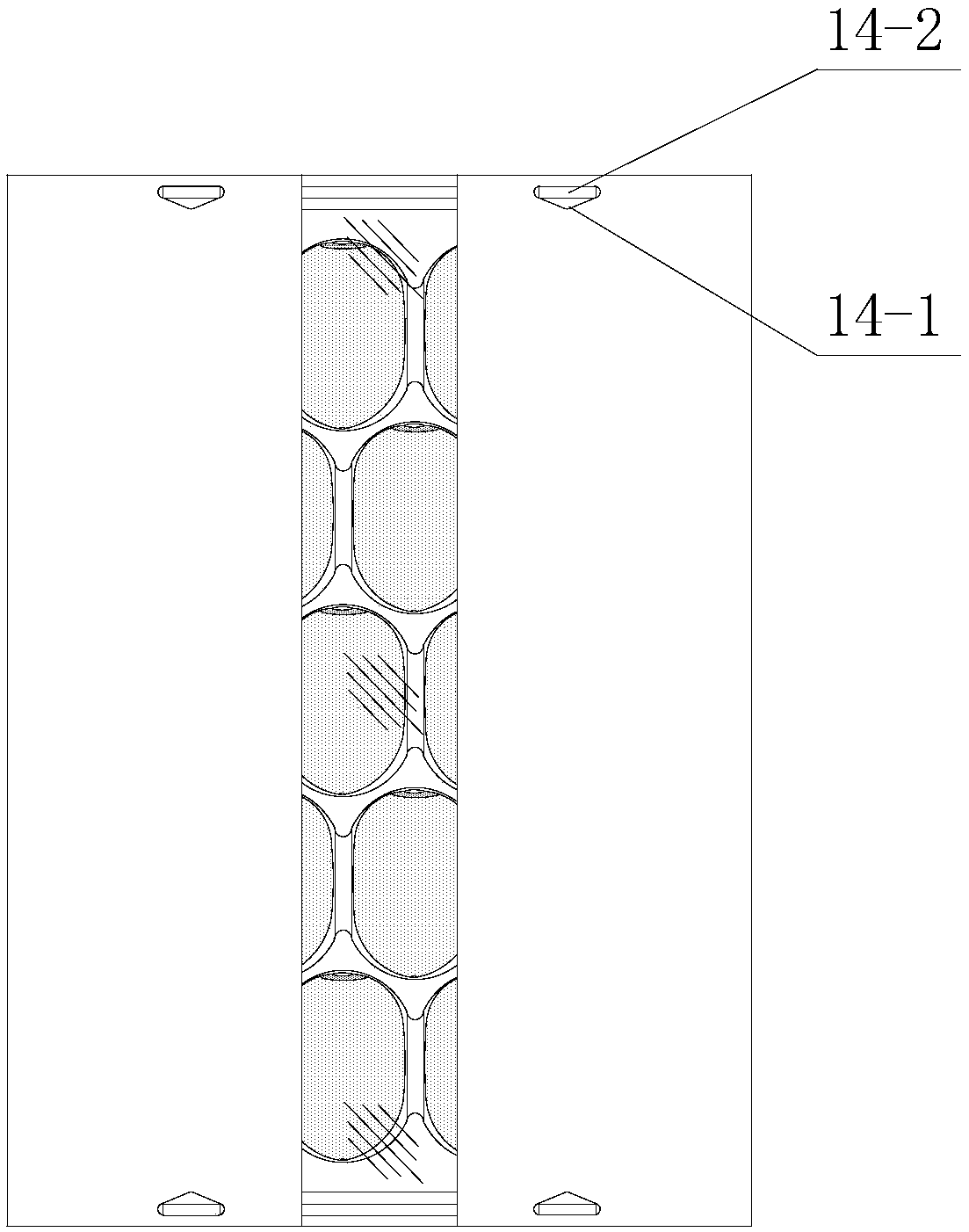

[0102] In this embodiment, a manipulator grabs type fruit automatic packaging equipment, such as Figure 4 As shown in , it is convenient to display the internal structure, and the frame, sealing plate, connecting components, etc. are omitted in the illustration. The equipment mainly includes a box conveyor 9, a blister tray bin 7, a suction cup manipulator 8, a film traction and cutting device 2, a fruit grasping device 1, a fruit conveyor 6, a film-coated packaging device 3, a lid-closing packaging device 4 and CCD camera 5; along the conveying direction of the carton, the box conveyor is successively provided with a film traction and cutting station 10, a fruit filling station 11, a film covering station 12 and a lid closing station 13; at the film traction and cutting station It is equipped with a film traction and slitting device. One side of the film traction and slitting station is also equipped with a blister tray bin. There is a fruit conveyor on the side, a CCD came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com