Automatic twisting equipment for cable

A technology of twisting equipment and cables, which is applied in the field of automatic cable twisting equipment, can solve problems such as troublesome production in large quantities, inability to adjust clamping, and high strength, and achieve the effects of convenient operation, convenient collection, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

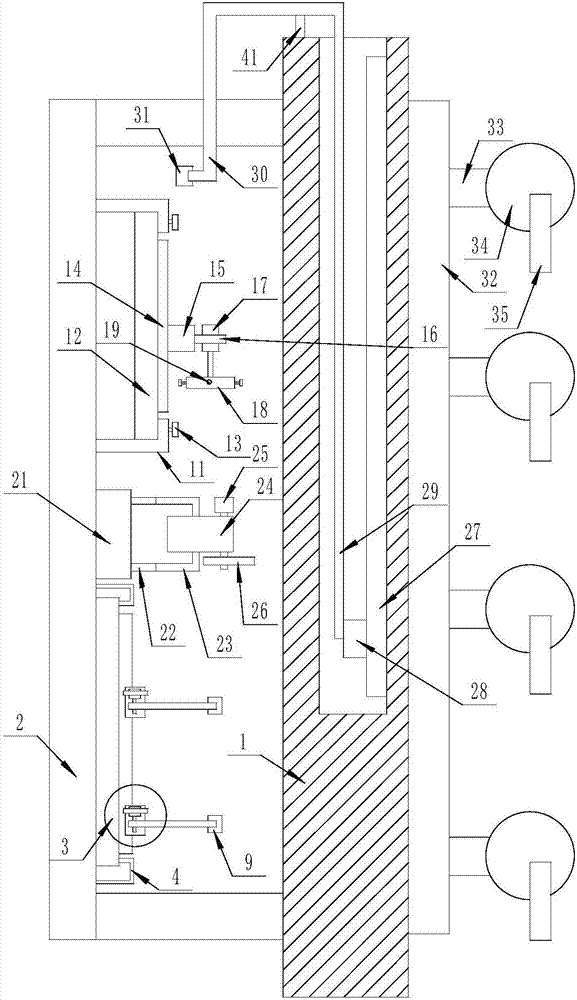

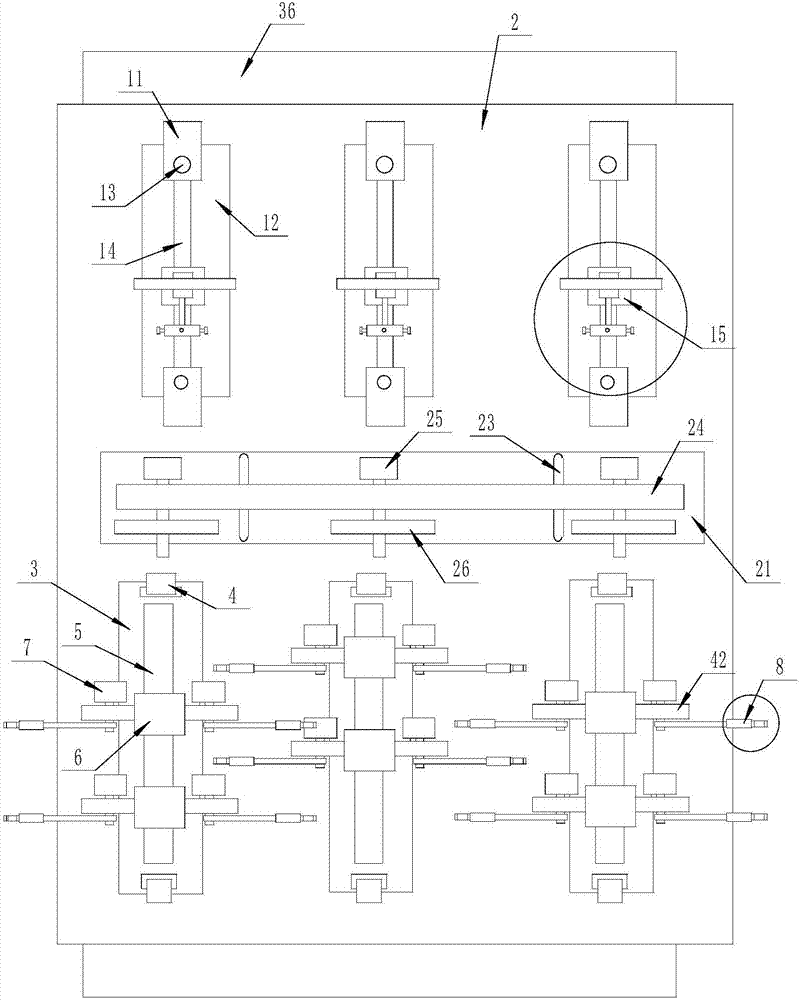

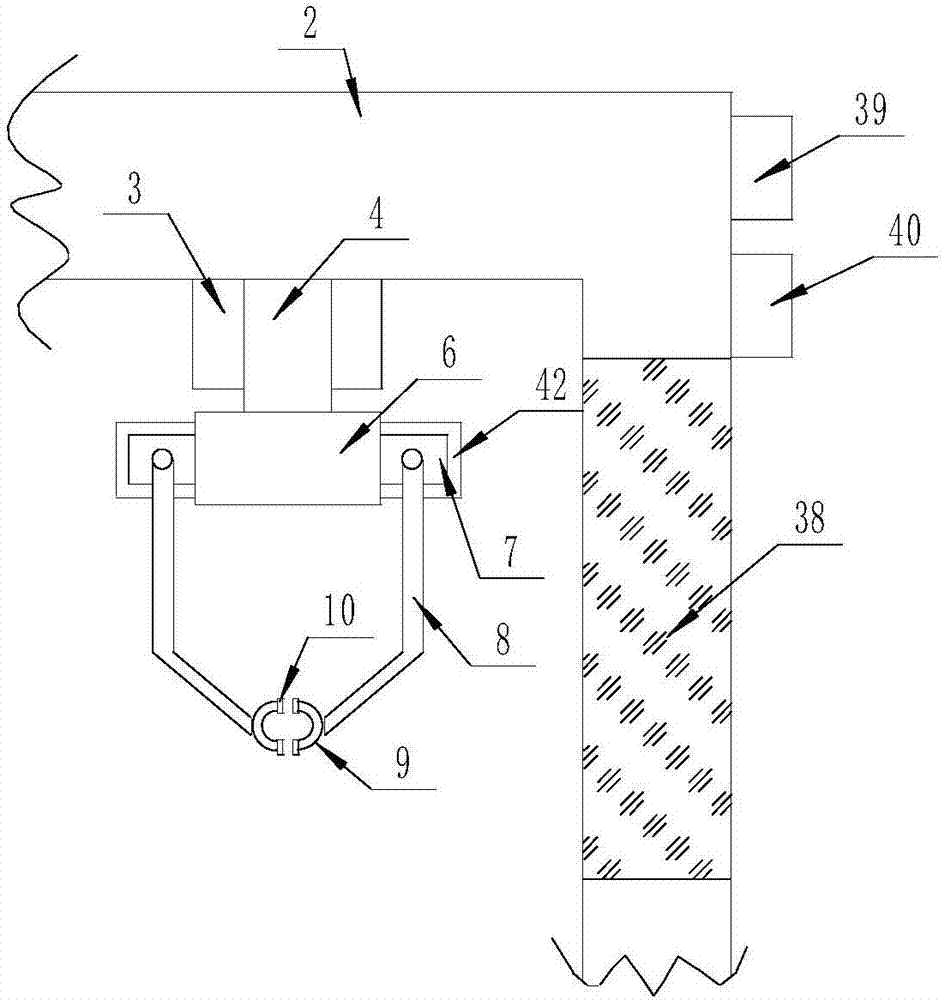

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8As shown, a cable automatic twisting device includes a strip-shaped bearing base 1, the upper surface of the strip-shaped bearing base 1 is fixedly connected to a strip-shaped work box 2, and the strip-shaped work box 2 is equipped with an automatic Twisting mechanism, the strip-shaped bearing base 1 is provided with a stretching and discharging mechanism, the lower surface of the strip-shaped bearing base 1 is provided with a moving mechanism, and the automatic twisting mechanism is processed on the strip-shaped working box 2 The strip-shaped openings on the two opposite side surfaces, the plurality of strip-shaped fixing plates 3 fixedly connected to the inner upper surface of the strip-shaped working box 2, and a group of strip-shaped openings opened at both ends of the lower surface of each strip-shaped fixing plate 3. Through holes, fixed frame 4 arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com