Light emitting element, light emitting device and electronic apparatus

A technology for light-emitting devices and light-emitting layers, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as operating failures of light-emitting components, and achieve the effect of reducing unevenness and excellent color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

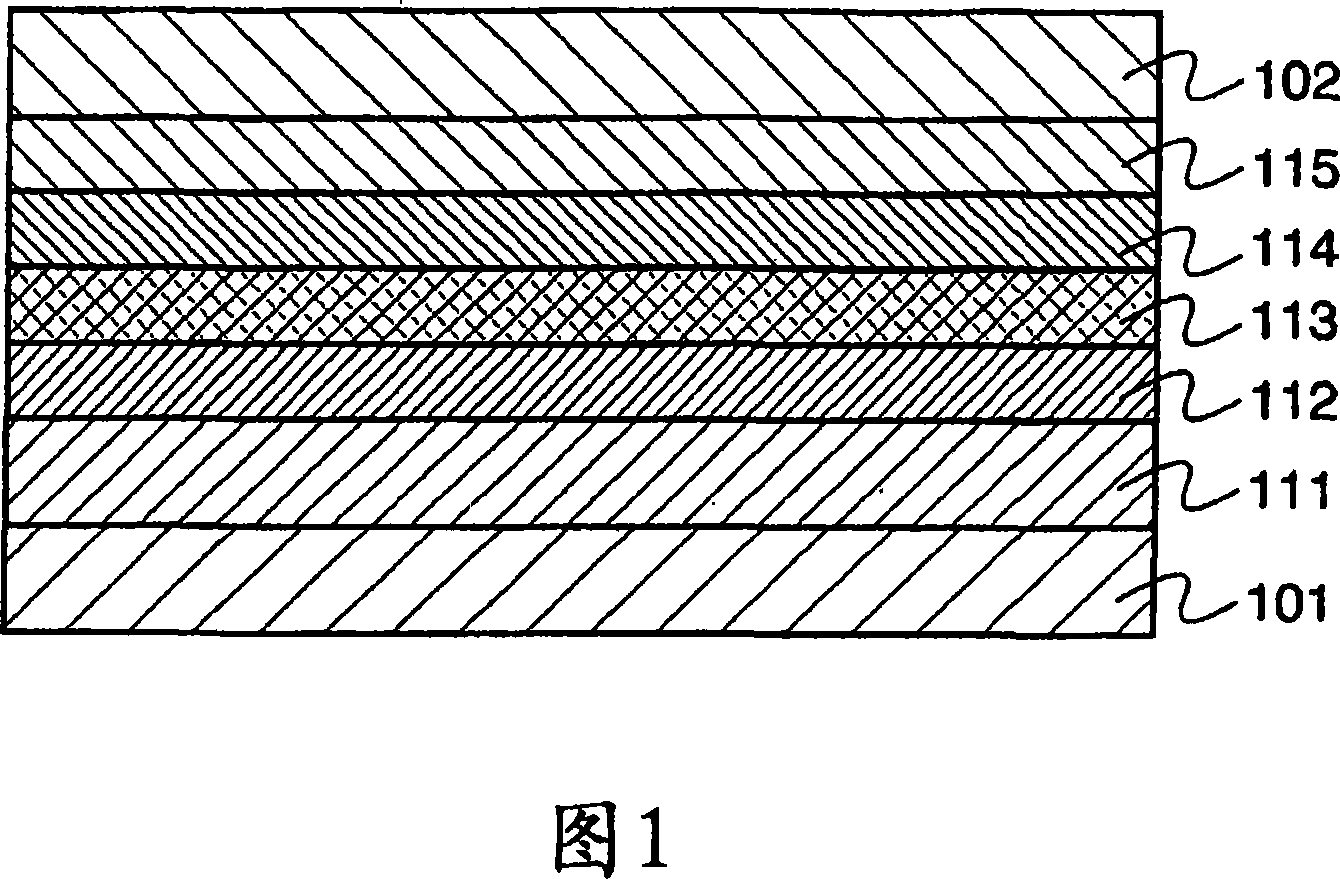

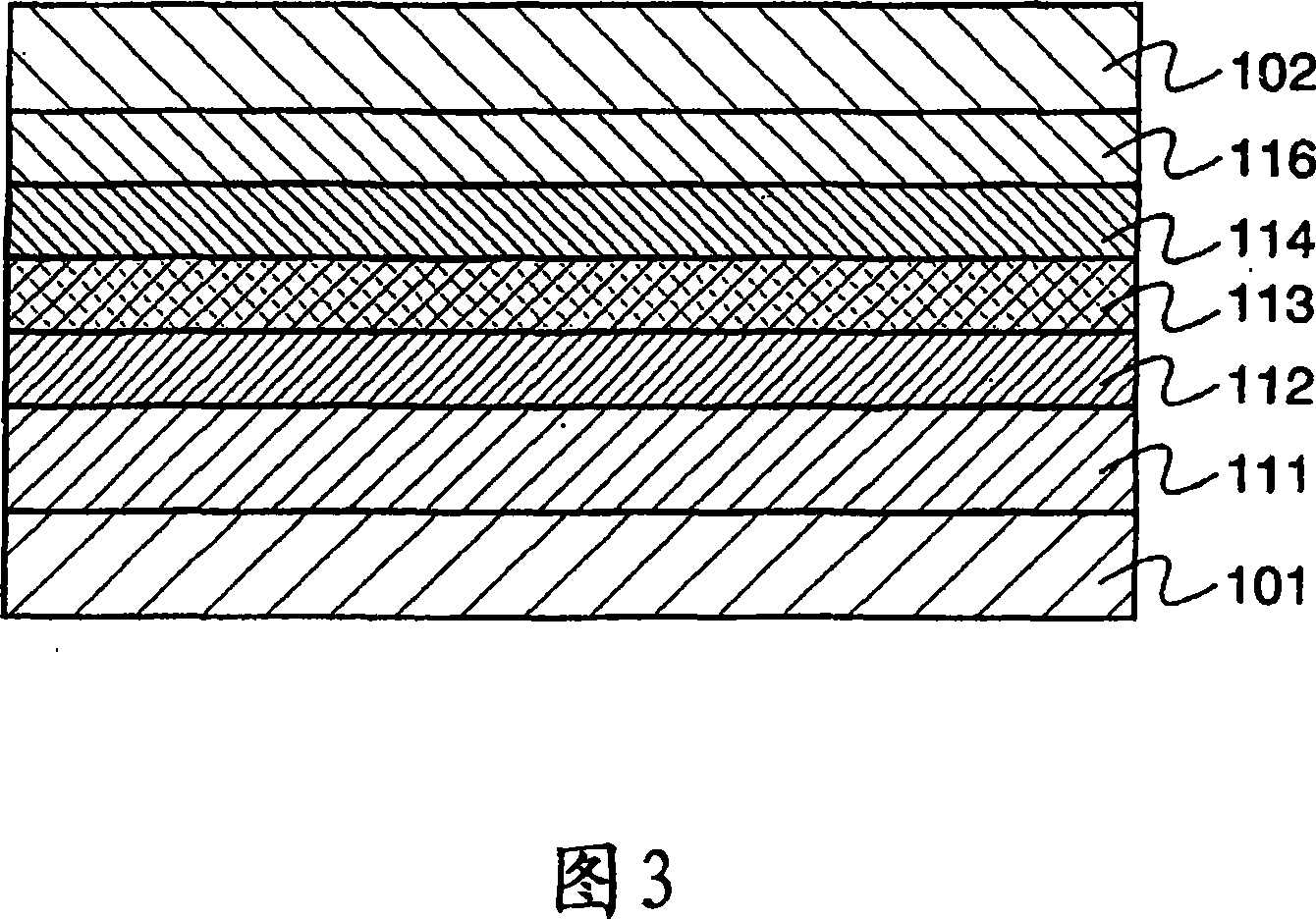

[0041] One mode of the light-emitting element of the present invention will be described with reference to FIG. 1 .

[0042] FIG. 1 shows a light emitting element having a light emitting layer 113 between a first electrode 101 and a second electrode 102 . In the light emitting element shown in FIG. 1 , the mixed layer 111 is provided between the light emitting layer 113 and the first electrode 101 . The hole transport layer 112 is disposed between the light emitting layer 113 and the mixing layer 111 , and the electron transport layer 114 and the electron injection layer 115 are disposed between the light emitting layer 113 and the second electrode 102 . In such a light-emitting element, when a voltage is applied to the first electrode 101 and the second electrode 102 so that the potential of the first electrode 101 is higher than the potential of the second electrode 102, holes are injected from the side of the first electrode 101 to emit light. In the layer 113, electrons a...

Embodiment approach 2

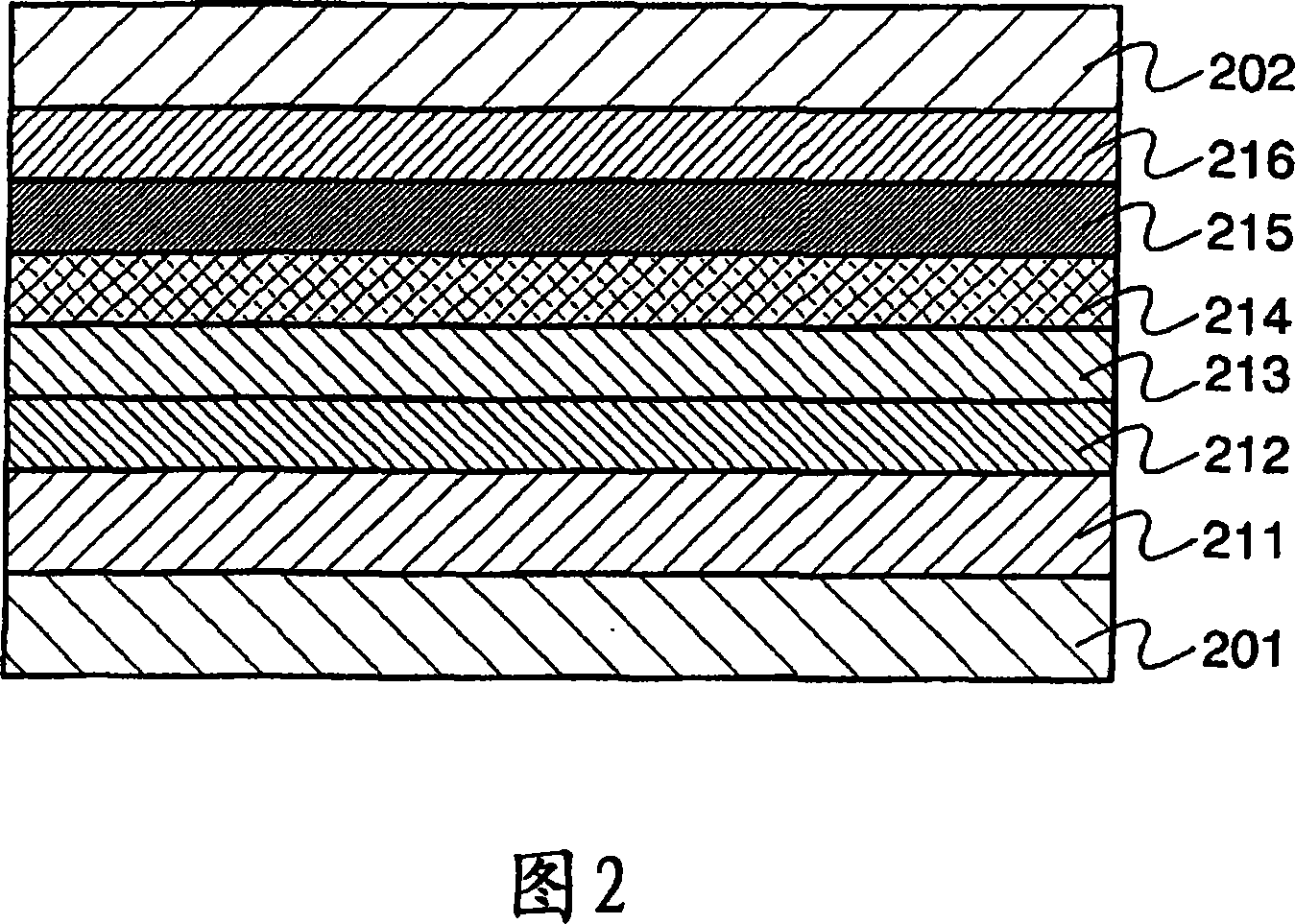

[0061] One mode of the light emitting element of the present invention is described with reference to FIG. 2 .

[0062] 2 shows a light emitting element with a light emitting layer 213, a first mixed layer 215 and a second mixed layer 216 between the first electrode 201 and the second electrode 202, wherein the light emitting layer 213 is closer to the first mixed layer than the first mixed layer 215. For the electrode 201 , the second mixed layer 216 is closer to the second electrode 202 than the first mixed layer 215 . In this light emitting element, the hole injection layer 211 and the hole transport layer 212 are provided between the light emitting layer and the first electrode 201 , and the electron transport layer 214 is provided between the light emitting layer 213 and the first mixed layer 215 . The first mixed layer 215 is a layer including an electron transport substance and one substance selected from alkaline metals, alkaline earth metals, alkaline metal oxides, al...

Embodiment approach 3

[0079]Next, one mode of the light-emitting element of the present invention will be described with reference to FIG. 20 . FIG. 20 shows a light emitting element having a plurality of light emitting layers, specifically a first light emitting layer 413a, a second light emitting layer 413b, and a third light emitting layer 413c between the first electrode 401 and the second electrode 402. This light-emitting element has a first mixed layer 421a and a second mixed layer 422a between the first light-emitting layer 413a and the second light-emitting layer 413b, and has a first mixed layer 421b between the second light-emitting layer 413b and the third light-emitting layer 413c. and the second mixed layer 422b. The first mixed layer 421a, 421b is a layer including an electron transport substance and a substance selected from alkaline metals, alkaline earth metals, alkaline metal oxides, alkaline earth metal oxides, alkaline metal fluorides, and alkaline earth metal fluorides. . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com