Preparation method of conductive ink vehicle

A technology of conductive ink and connecting material, which is applied in ink, household utensils, applications, etc., can solve the problems of low-temperature brittleness, poor solubility of acrylic resin, and high-temperature stickiness, etc., and achieve low viscosity, good non-crystallization, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of urethane acrylate monomer: Weigh 6.6678 g isophorone diisocyanate IPDI and 3.9000 g hydroxyethyl methacrylate HEPA for a ratio test, and add 2 g of the catalyst hydroquinone. Before the start of the experiment, dry 30ml of acetone in 4A molecular sieve for 1 hour; then put the weighed IPDI and hydroquinone into a three-necked flask, soak in an oil bath, then add the dried acetone, and use an electric mixer Stir at a speed of 300r / min at 40℃ for 100min, add HEPA dropwise to the three-necked flask with a dropper, and measure the -NCO content every half an hour. When the -NCO content reaches the theoretical value of the reaction (12.60%), stop the reaction , Collect reactants, test and analyze.

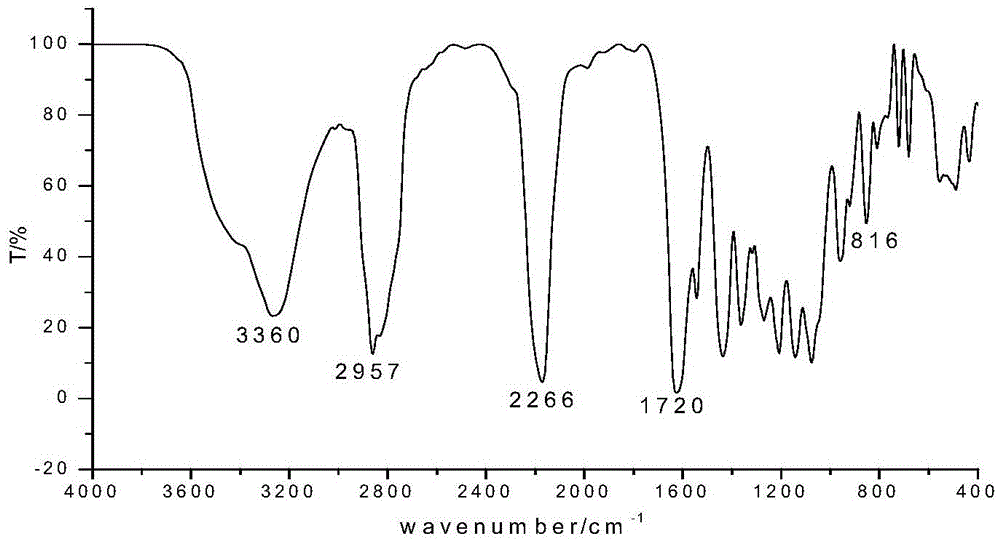

[0016] Fourier infrared spectrum analyzer was used to characterize and analyze the obtained product. From figure 1 The characterization results of infrared absorption spectroscopy showed that the carbamate group and the corresponding acrylic group existed, and the abs...

Embodiment 2

[0018] Prepare the first generation hyperbranched polyester polyol HBPE-1: In a three-necked flask with a thermometer and a condenser, add 5.4316g pentaerythritol, 0.2780g p-toluenesulfonic acid and 5.3517g DMPA in sequence, and add 20ml acetone and ethanol to mix The liquid is dissolved; the temperature is increased to 140°C, the magnet is added, and nitrogen is put into the oil bath for 40 minutes to remove bubbles and water; the reactants are melted and react until the acid value does not change. After the product was obtained, it was washed several times with ethyl acetate and water, and then placed in a vacuum drying oven at a temperature of 55° C. and an air pressure of 0.1 MPa for 12 hours to obtain the first-generation hyperbranched polyester multi-component Alcohol HBPE-1.

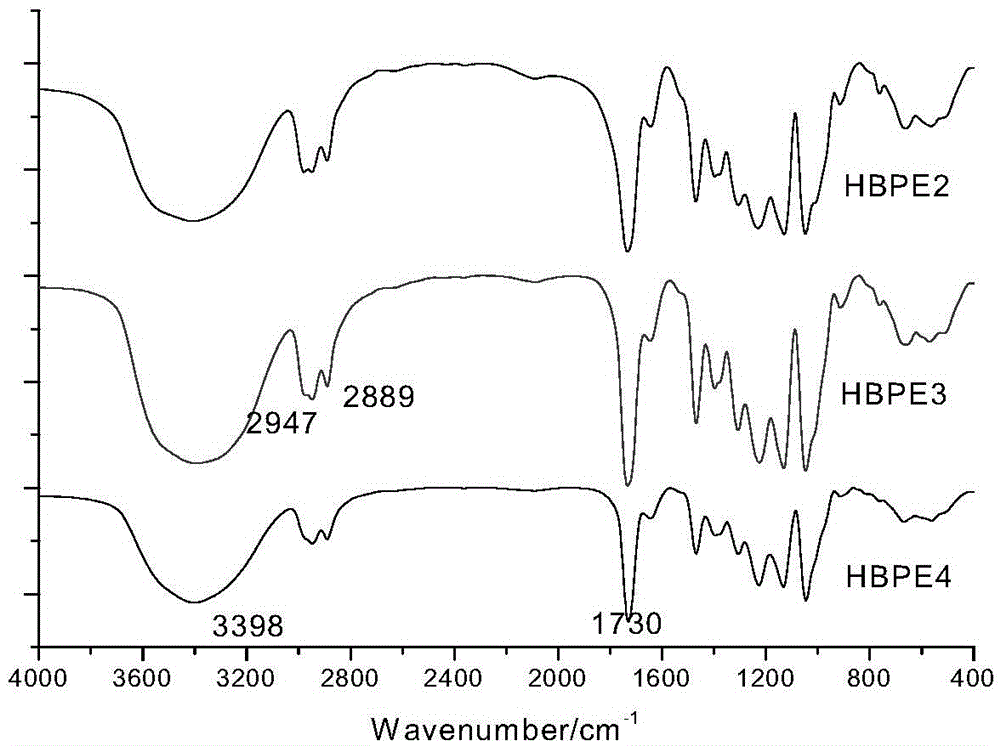

[0019] Prepare the second-generation hyperbranched polyester polyol HBPE-2, the third-generation hyperbranched polyester polyol HBPE-3 and the fourth-generation hyperbranched polyester polyol HBPE-4 ...

Embodiment 3

[0022] The urethane acrylate monomer UA prepared in Example 1 and the third-generation hyperbranched polyester polyol product (HBPE-3) prepared in Example 2 were mixed into a three-necked flask at a ratio of 1:1. Add acetone as a solvent, make them fully contact in the solvent and fully react. The reaction temperature is 70℃, and the mixture is refluxed until the peak in the Fourier spectrum is at 2261cm -1 The -NCO group disappeared. Nitrogen gas was introduced to carry out a reduced pressure reaction for 40 minutes to remove bubbles, the product was rotary evaporated to remove the residual solvent in the product, and finally the product was dried in a vacuum.

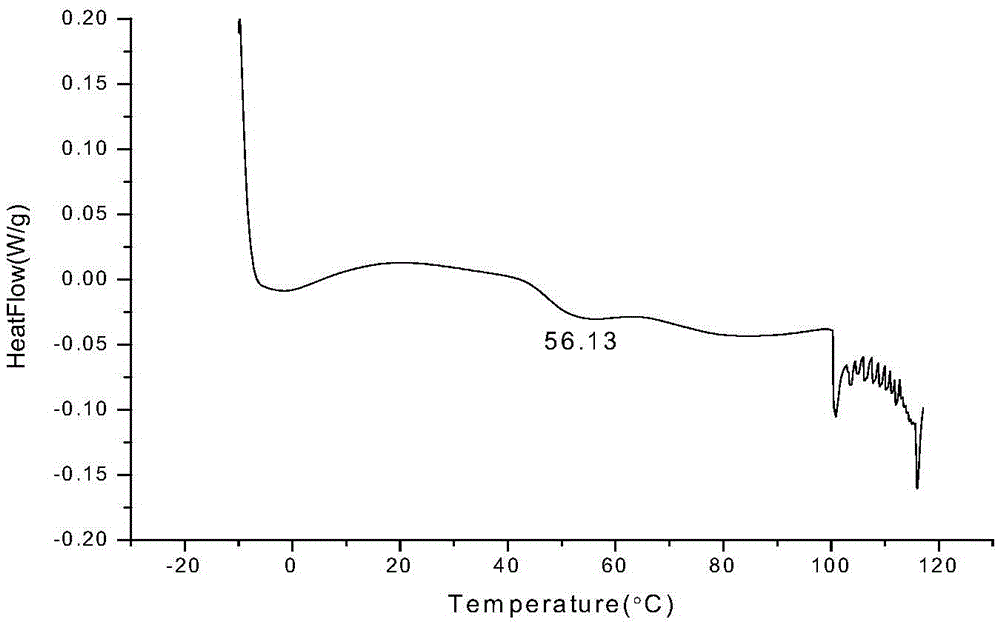

[0023] Fourier infrared spectrometer and DSC differential scanning calorimeter were used to characterize and analyze the obtained products. From Figure 5 According to the characterization results of infrared absorption spectroscopy, the product has absorption peaks of carbamate groups and acrylate groups, and the absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com