Speed-variable circular and longitudinal seam welder applied to multi-specification tank bodies

A multi-standard, longitudinal seam welding technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of small welding speed and only changing range, and achieve low production cost, compact structure and stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention can be used in the related fields of machinery, chemical industry, pump industry, etc. for the girth welding between the main shell and the end cover of relatively large tank containers, gas storage tanks, oil storage tanks and other devices, as well as the welding of the main shell Longitudinal seam welding when closing.

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments, and any improvement or replacement in the basic spirit of the present invention still belongs to the scope of protection claimed in the claims of the present invention.

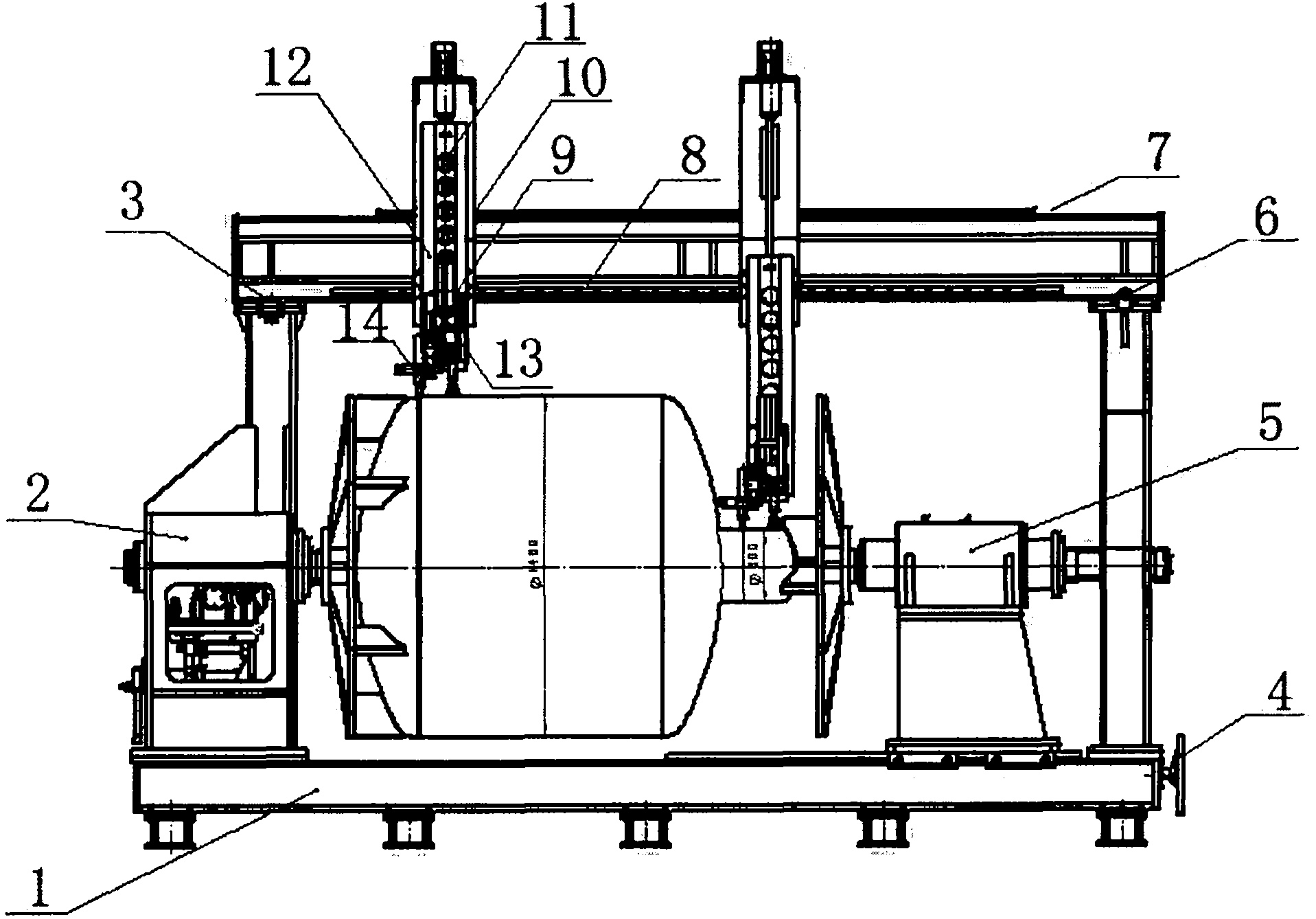

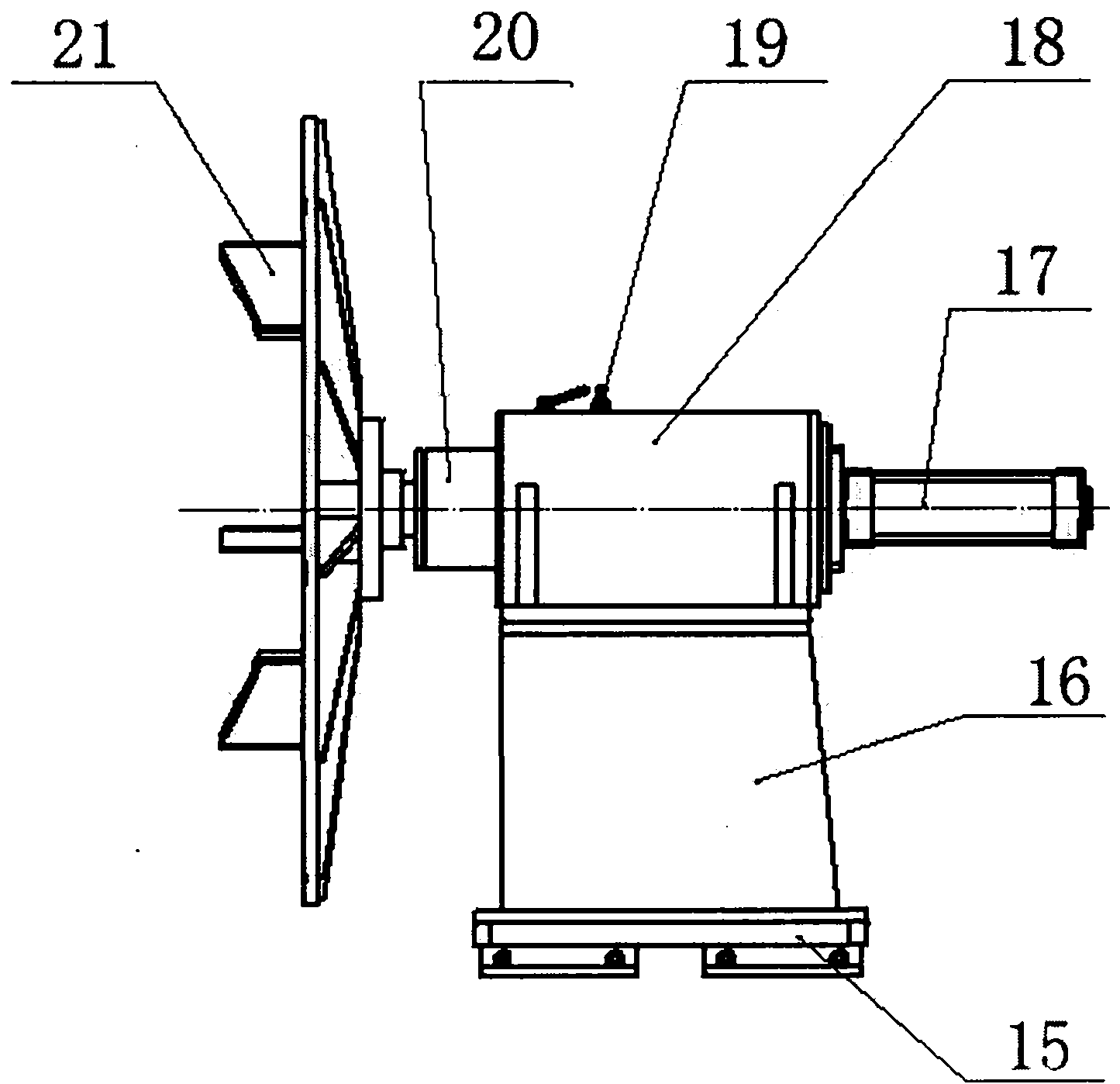

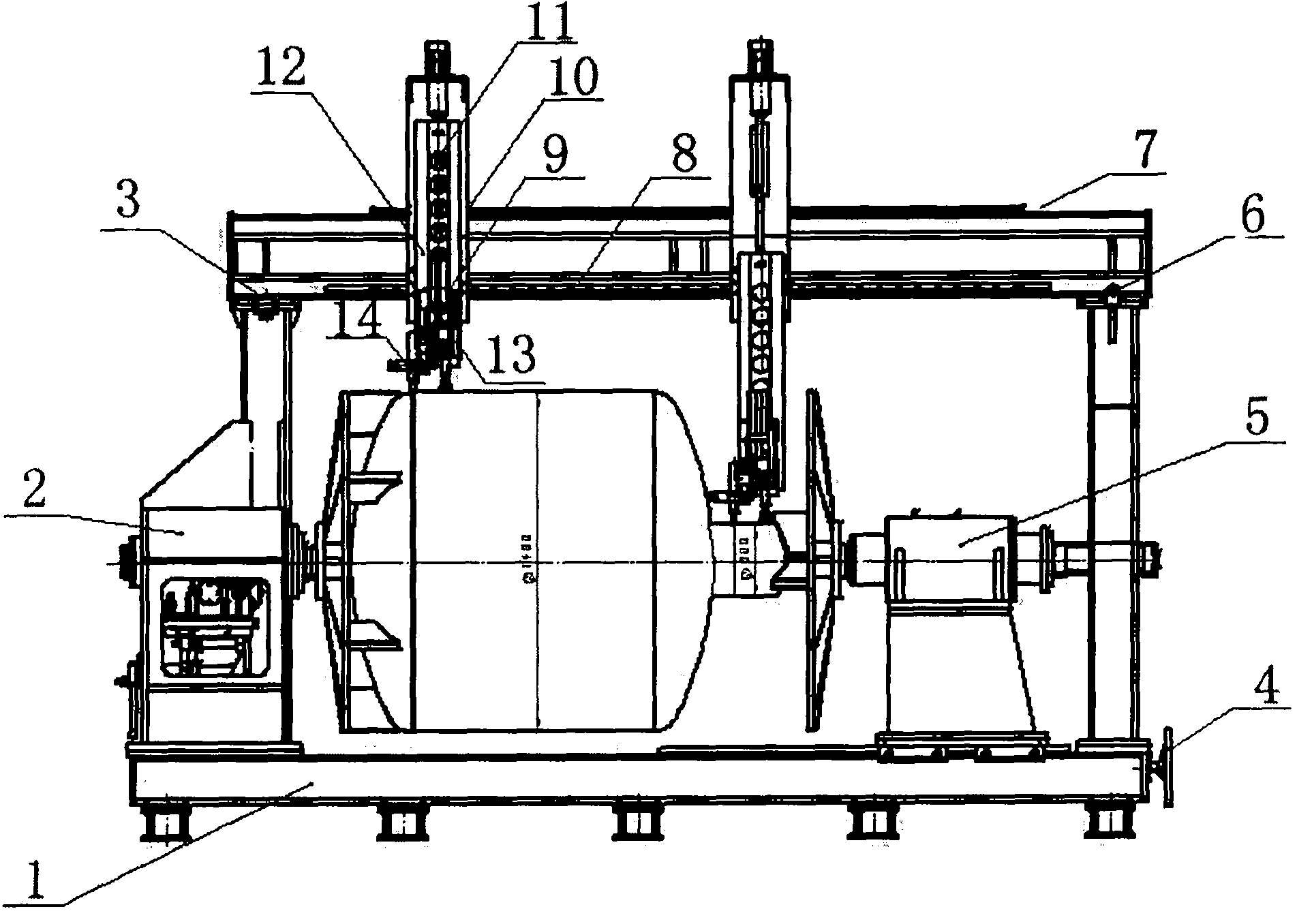

[0015] Please refer to Figure 1, a variable speed ring and longitudinal seam welding machine applied to multi-standard tanks in the present invention mainly consists of a bed (1), a bedside box (2), a beam mechanism (12) and a tail Four major parts such as seat (5) form. Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com