Tailstock type vertical take-off and landing unmanned aerial vehicle

An unmanned aerial vehicle, vertical take-off and landing technology, applied in the field of unmanned aerial vehicles, can solve problems such as flight restrictions and flight dangers, and achieve the effects of simplified power, simple structure, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

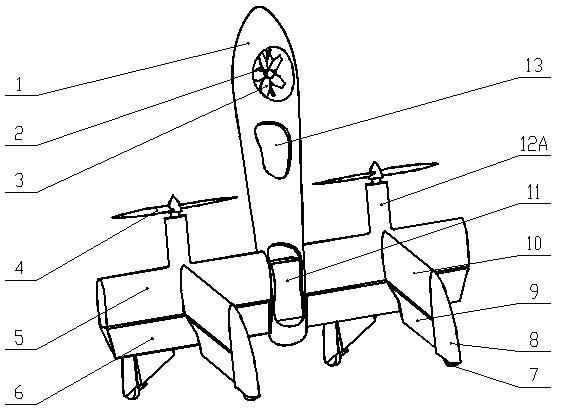

[0015] Embodiment one: see figure 1 , a tail-sitting vertical take-off and landing unmanned aerial vehicle, comprising a fuselage 1, wings 5 and a vertical tail 10, a support frame 2 is arranged at the head of the fuselage 1, and a pitch fan 3 is installed on the support frame 2, The middle part of the fuselage 1 has a cabin 13, and a built-in battery 11 in the tail; the wing 5 is connected to the tail of the fuselage 1, and four vertical tail fins 10 are symmetrically distributed up and down, left and right, and the rear of the wing 5 A roll and pitch control rudder surface 6 is installed at the top; two mutually independent motors 12A are fixed at the junction of the wing 5 and the vertical tail 10, and each of the two motors 12A drives a propeller 4; the four vertical tails 10 rear portions are respectively equipped with a yaw control rudder surface 9 and a landing gear 8, and each landing gear 8 rear portion is equipped with a universal roller 7; the pitch fan 3 is drive...

Embodiment 2

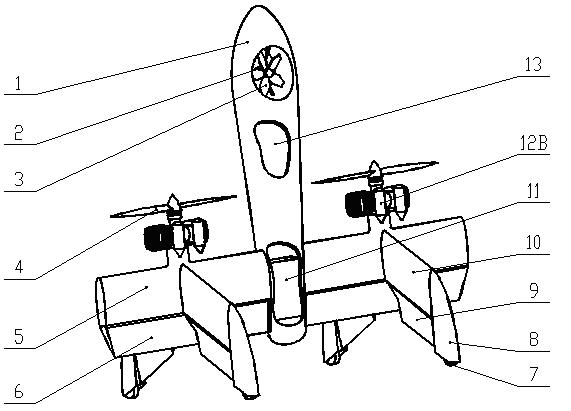

[0017] Embodiment two: see figure 2 , a tail-sitting vertical take-off and landing unmanned aerial vehicle, comprising a fuselage 1, wings 5 and a vertical tail 10, a support frame 2 is arranged at the head of the fuselage 1, and a pitch fan 3 is installed on the support frame 2, The middle part of the fuselage 1 has a cabin 13, and a built-in battery 11 in the tail; the wing 5 is connected to the tail of the fuselage 1, and four vertical tail fins 10 are symmetrically distributed up and down, left and right, and the rear of the wing 5 A roll and pitch control rudder surface 6 is installed at the top; two mutually independent motors 12B are fixed at the junction of the wing 5 and the vertical tail 10, and each of the two motors 12B drives a propeller 4; the four vertical tails 10 rear portions are respectively equipped with a yaw control rudder surface 9 and a landing gear 8, and each landing gear 8 rear portion is equipped with a universal roller 7; the pitch fan 3 is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com