Temperature fuse module

A technology of top block and metal conductor, applied in the direction of thermal switch components, etc., can solve the problems of thermal protector being unable to withstand large current impact, long response time, etc., to achieve the effect of rapid power cut off, sensitive response, and prevention of fire and burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

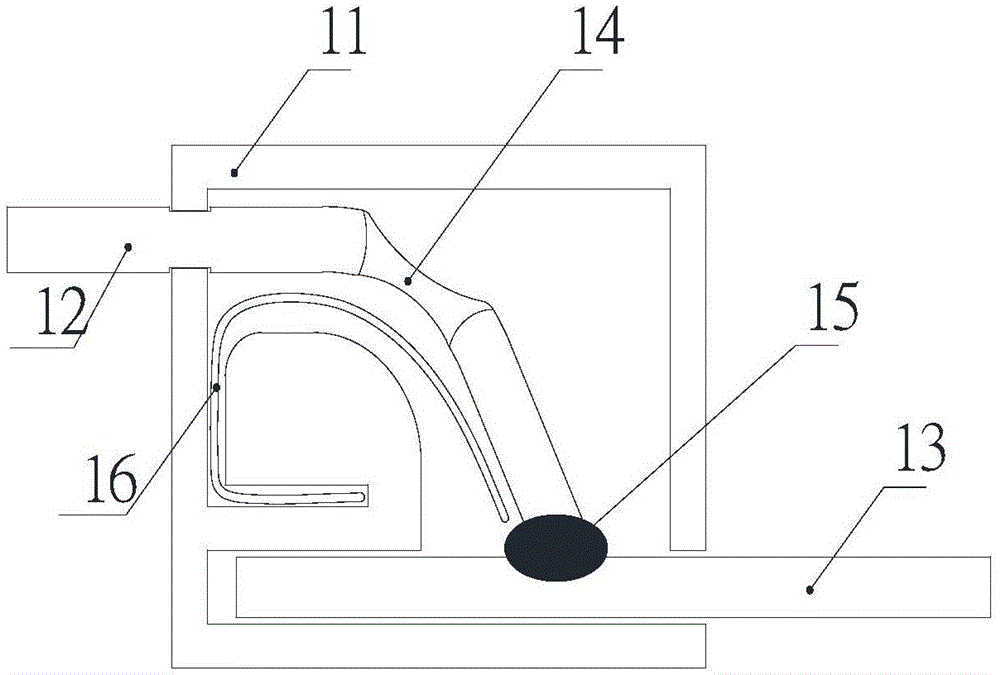

[0020] Such as figure 1 As shown, a thermal fuse module of the present invention includes an insulating housing 11, a first metal conductor 12, a second metal conductor 13 and an elastic structure 16, and a bending point 14 is provided on the first metal conductor 12, and the first The metal conductor 12 and the second metal conductor 13 are welded by the fusible alloy 15, and the first metal conductor 12 and the second metal conductor 13 respectively extend outside the insulating housing 11 to form the electrode end of the connecting circuit; the elastic structure 16 leans against the On the first metal conductor 12 , when the fusible alloy 15 is melted, the elastic structure 16 can effectively disconnect the first metal conductor 2 and the second metal conductor 3 .

Embodiment 2

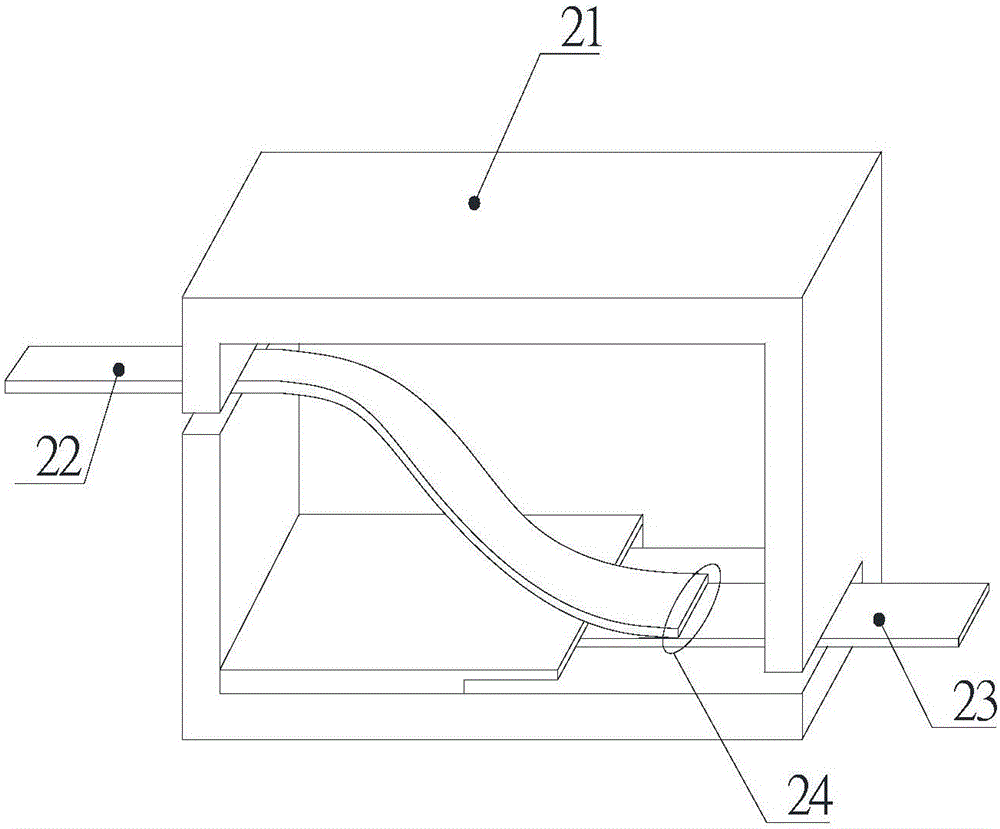

[0022] Such as figure 2 As shown, a thermal fuse module of the present invention includes an insulating housing 21, an elastic structure 22, a metal conductor 23, the elastic structure 22 and the metal conductor 23 are welded by a fusible alloy 24, the elastic structure 22 and the metal conductor 23 They respectively extend outside the insulating casing 21 to form electrode terminals connecting the circuit; when the fusible alloy 24 melts, the elastic structure 22 can be effectively disconnected from the metal conductor 23 .

Embodiment 3

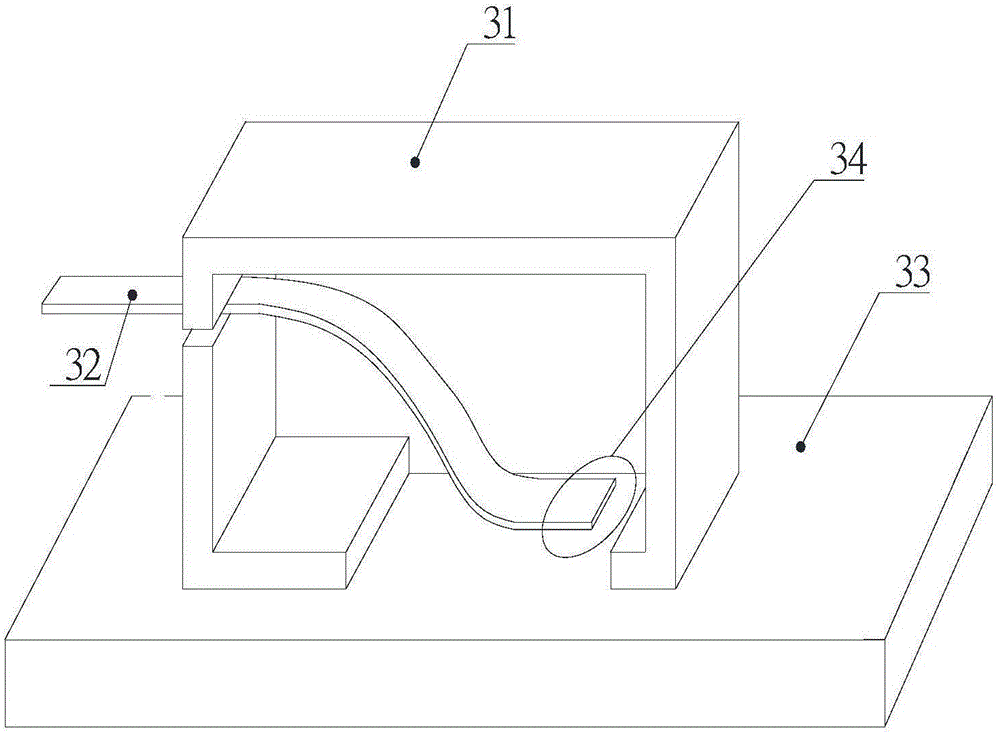

[0024] Such as image 3 As shown, a thermal fuse module of the present invention includes an insulating housing 31, an elastic structure 32, the elastic structure 32 is welded to an object 33 to be installed through a fusible alloy 34, and the elastic structure 32 extends outside the insulating housing 31. The electrode end of the connection circuit is formed; when the fusible alloy 34 is melted, the elastic structure 32 can be effectively disconnected from the object 33 to be installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com