Non-successional wettability modifying based bionic anti-icing surface

A wettability and anti-icing technology, applied in coatings and other directions, can solve problems such as high energy consumption and environmental pollution, and achieve the effects of delaying freezing time, reducing damage, and reducing adhesion strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

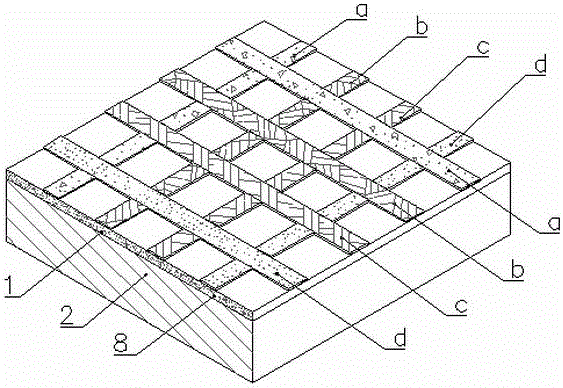

[0026] Such as image 3 As shown, the surface of the material is uniformly coated with a layer of coating base by spraying technology, and a (titanium dioxide hydrophobic coating), b (polytetrafluoroethylene particle coating), c (ferric oxide nano-coating), d (Silicon-containing hydrophobic coating) Four coatings with different hydrophobic properties are coated on the surface of the material along the longitudinal and transverse directions, so that the hydrophobic coating is distributed in a grid-like pattern on the surface of the material. Based on the actual use requirements, the horizontal and vertical lengths of each coating on the surface of the workpiece can be adjusted, so that the surface of the material has a variety of different wetting characteristics, and the surface of the material presents a "well" shape distribution.

[0027] The surface of the workpiece is coated with hydrophobic coatings with different wetting characteristics, which not only reduces the amount...

Embodiment 2

[0029] Such as Figure 5 As shown, four kinds of a (titanium dioxide hydrophobic coating), b (polytetrafluoroethylene particle coating), c (ferric oxide nano-coating) and d (silicon-containing hydrophobic coating) were applied on the surface of the material by spraying technology. The hydrophobic coating is evenly coated on the surface of the material, and the adjacent areas need to be coated with coatings with different wetting properties, and the distribution form presents a honeycomb shape. According to the icing problem of components in actual working conditions, the distribution form of the hydrophobic coating can be in a densely distributed honeycomb shape, so that the material surface per unit area has more different wetting types. The hydrophobic coatings with different wetting properties on the surface of the components can be sprayed with plasma spraying technology, supersonic spraying technology, nano spraying technology and other spraying technologies, and the coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com