Processing method for inner hole of cylinder

A processing method and inner hole technology are applied in the field of metal parts processing and manufacturing to achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A process for manufacturing a dump truck lift cylinder with a bore of 200 mm, a stroke of 1000 mm, and a pressure of 16 MPa.

[0025] 1. Preparation of materials: Select No. 45 carbon seamless steel pipe with an outer diameter of 232 mm and a thickness of 18 mm as the raw material, and cut the seamless steel pipe into cylinder blanks with a length of 1000 mm according to the design requirements;

[0026] 2. Pretreatment: Carry out quenching and tempering treatment on the cylinder blank and straighten it to ensure that the hardness of the cylinder blank is HRC28~32, and the bending is not more than 3 mm; the two ends of the pretreated cylinder blank are turned out of the boring hole Position the spigot by process, and weld the external components of the cylinder body;

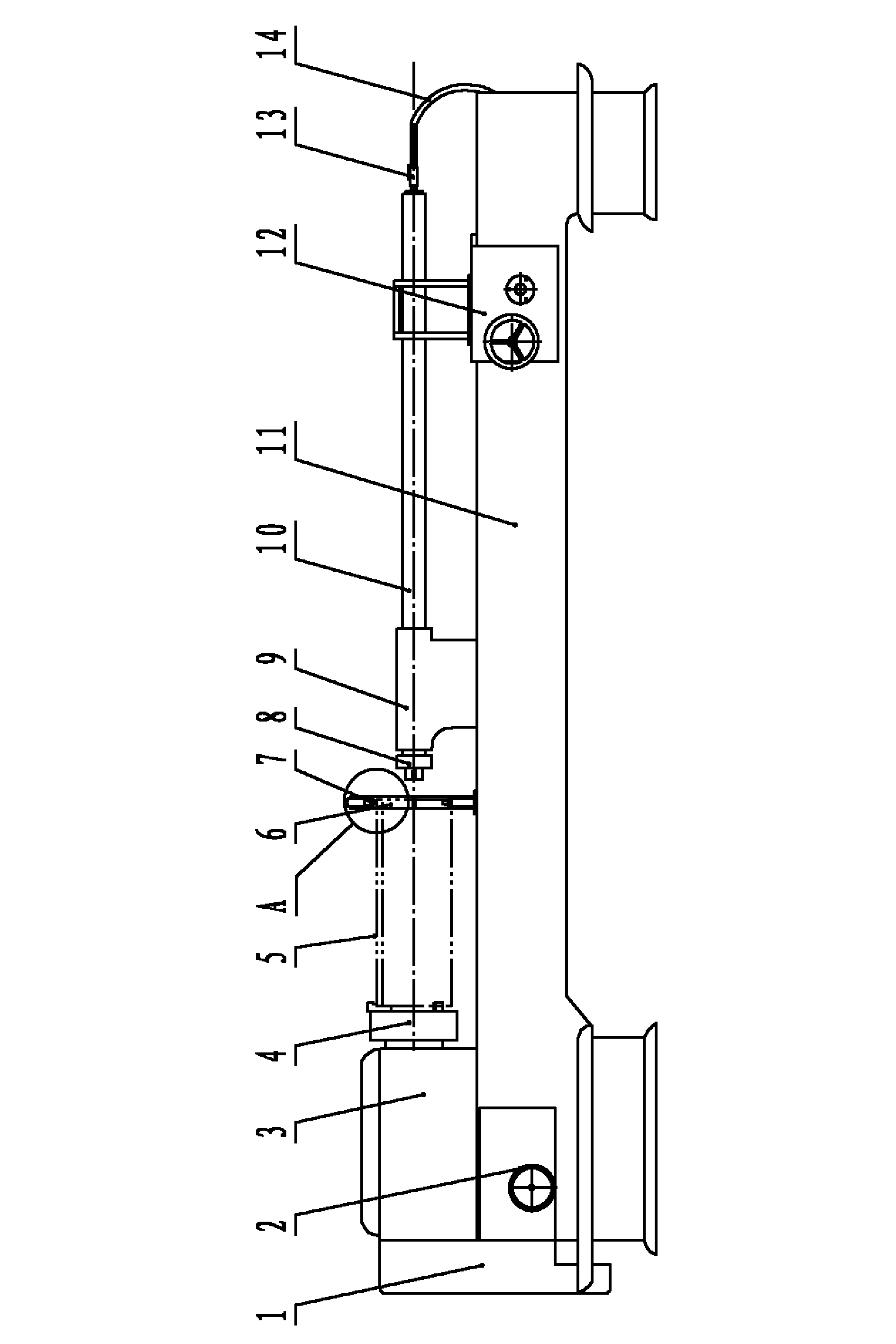

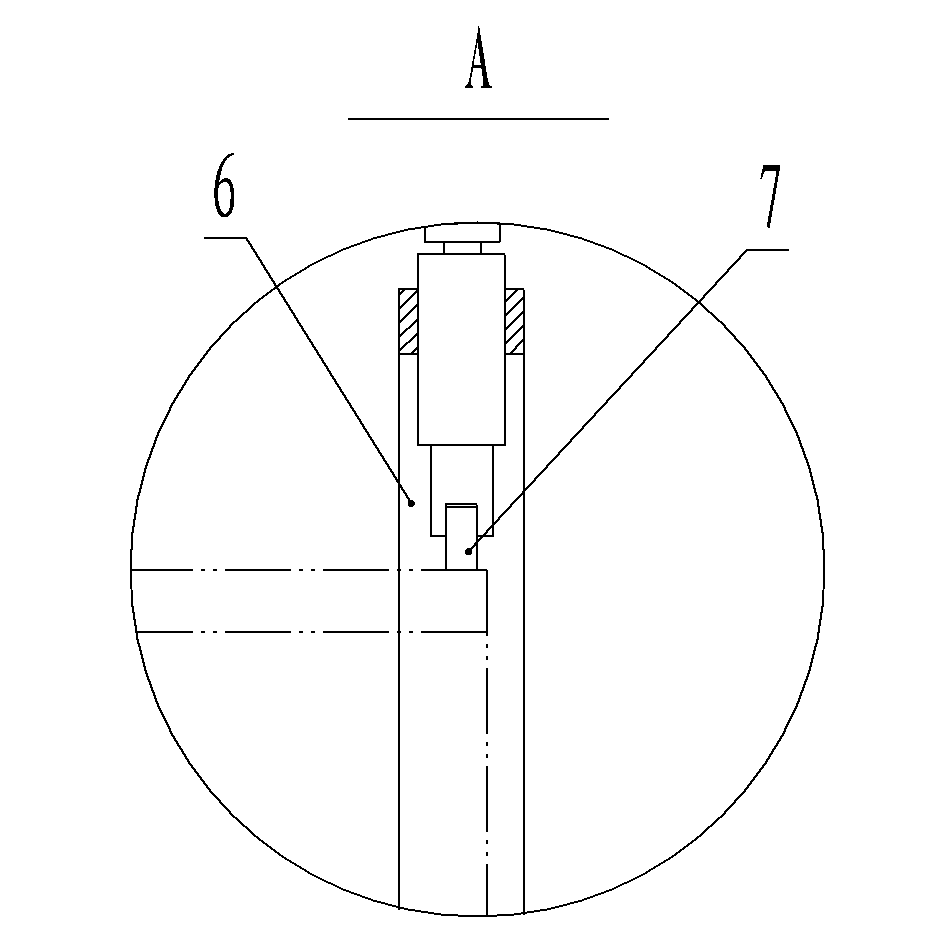

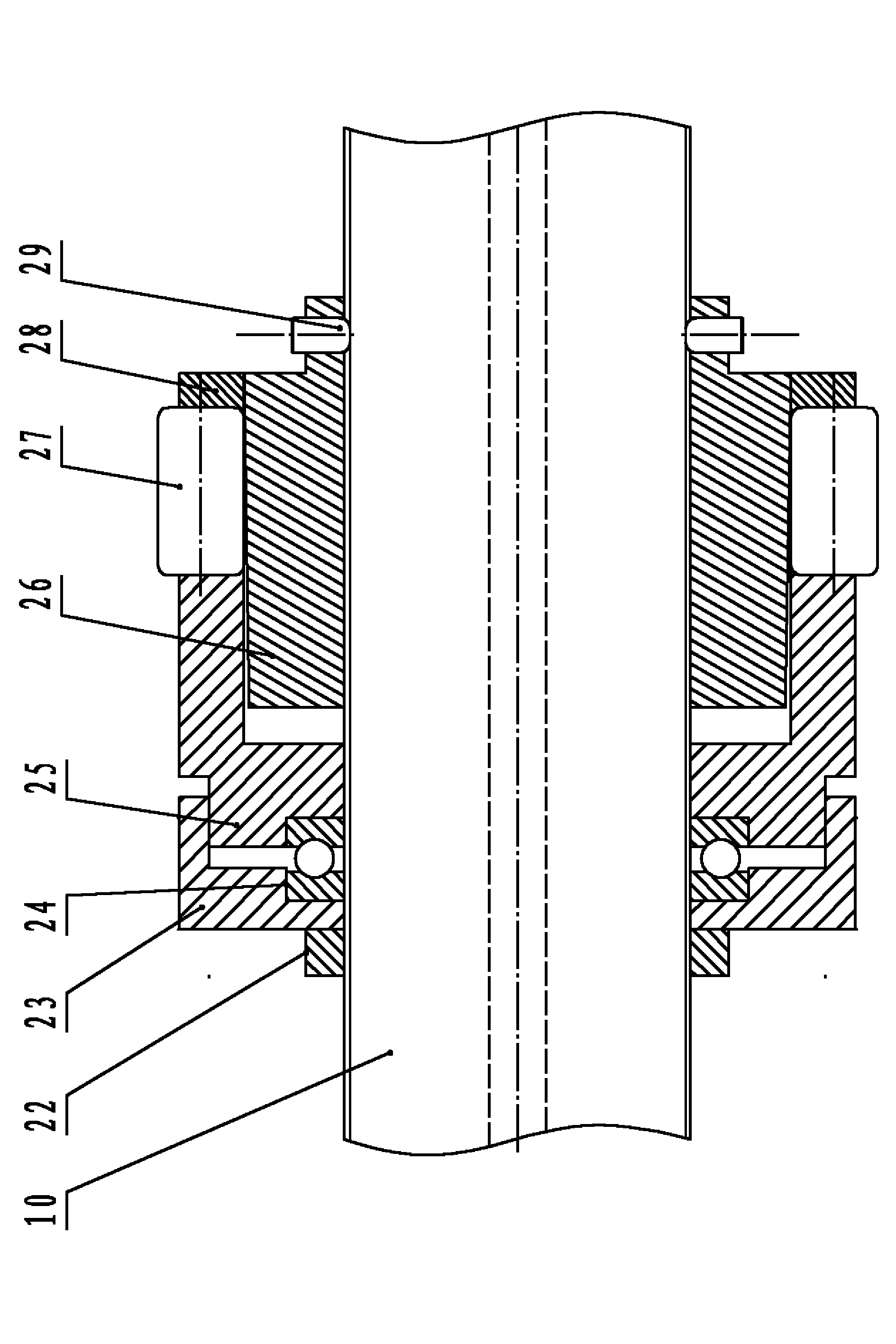

[0027] 3. Rough boring: The inner hole of the rough boring is processed on a special machine tool, and one end of the cylinder blank is clamped on the chuck of the special machine to...

Embodiment 2

[0033] Embodiment 2: A process for manufacturing a dump truck lift cylinder with a bore of 160 mm, a stroke of 1000 mm, and a pressure of 16 MPa.

[0034] In this embodiment, except that the processing parameters of rough boring, fine boring and rolling processing are different from those of embodiment 1, other parts are the same as those of the above-mentioned embodiment 1, and the processing parameters of rough boring, fine boring and rolling processing are:

[0035] Rough boring: cutting speed 80 m / min, cutting depth 2 mm, feed rate 0.5 mm / rev;

[0036] Fine boring: cutting speed 100 m / min, cutting depth 0.5 mm, feed rate 1.3 mm / rev;

[0037] Rolling: The radius of the transition circle between the cylindrical surface of the roller and the two end faces is 3.5 mm; the rolling speed is 100 m / min; the rolling depth is 0.1 mm; the feed rate is 1.3 mm / rev .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com