Tail device and tail dragging method

A hoisting method and equipment technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of large manpower investment, equipment resource occupation, and long preparation period for auxiliary equipment, and achieve low construction requirements, reduce hoisting costs, and purchase low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

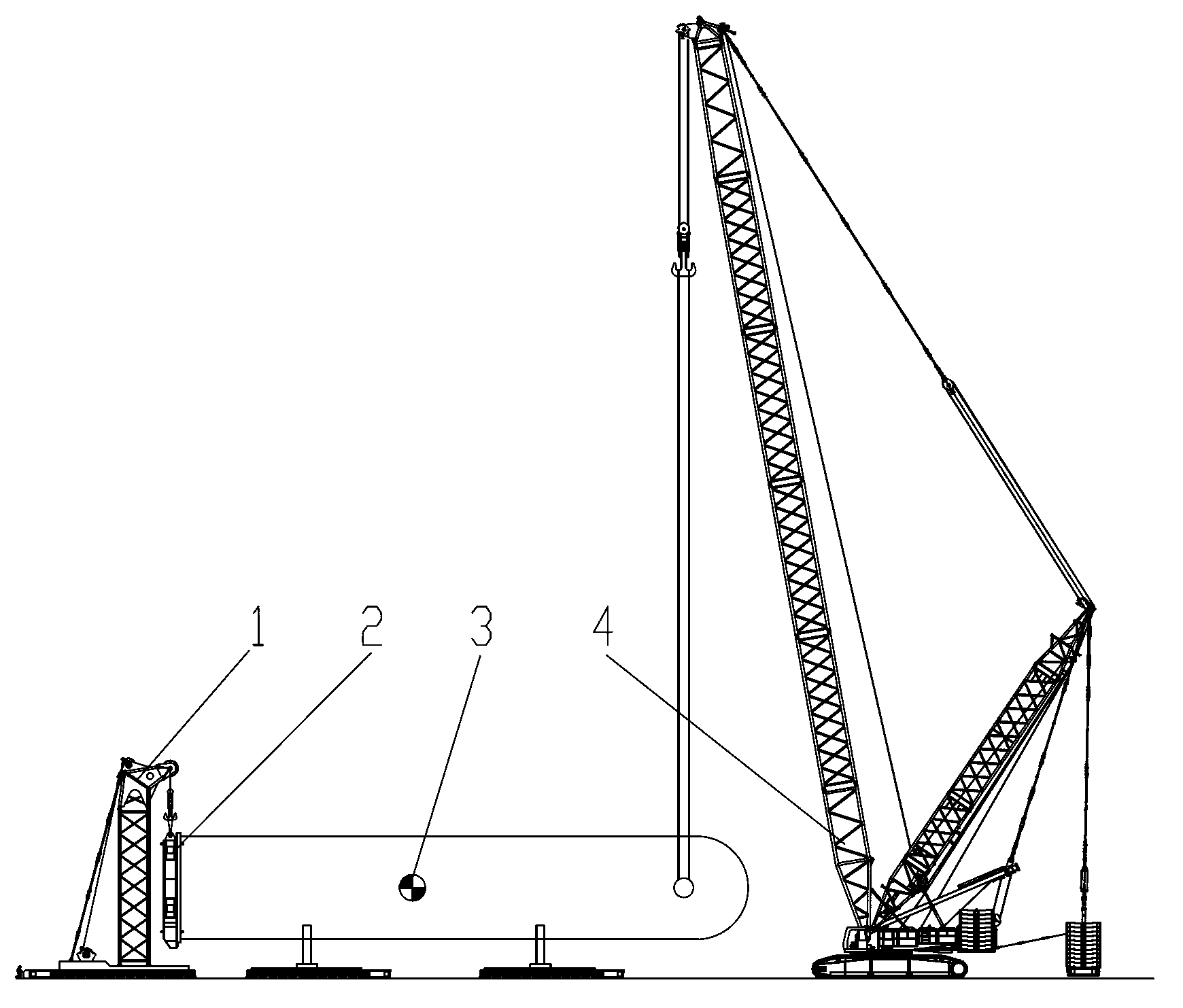

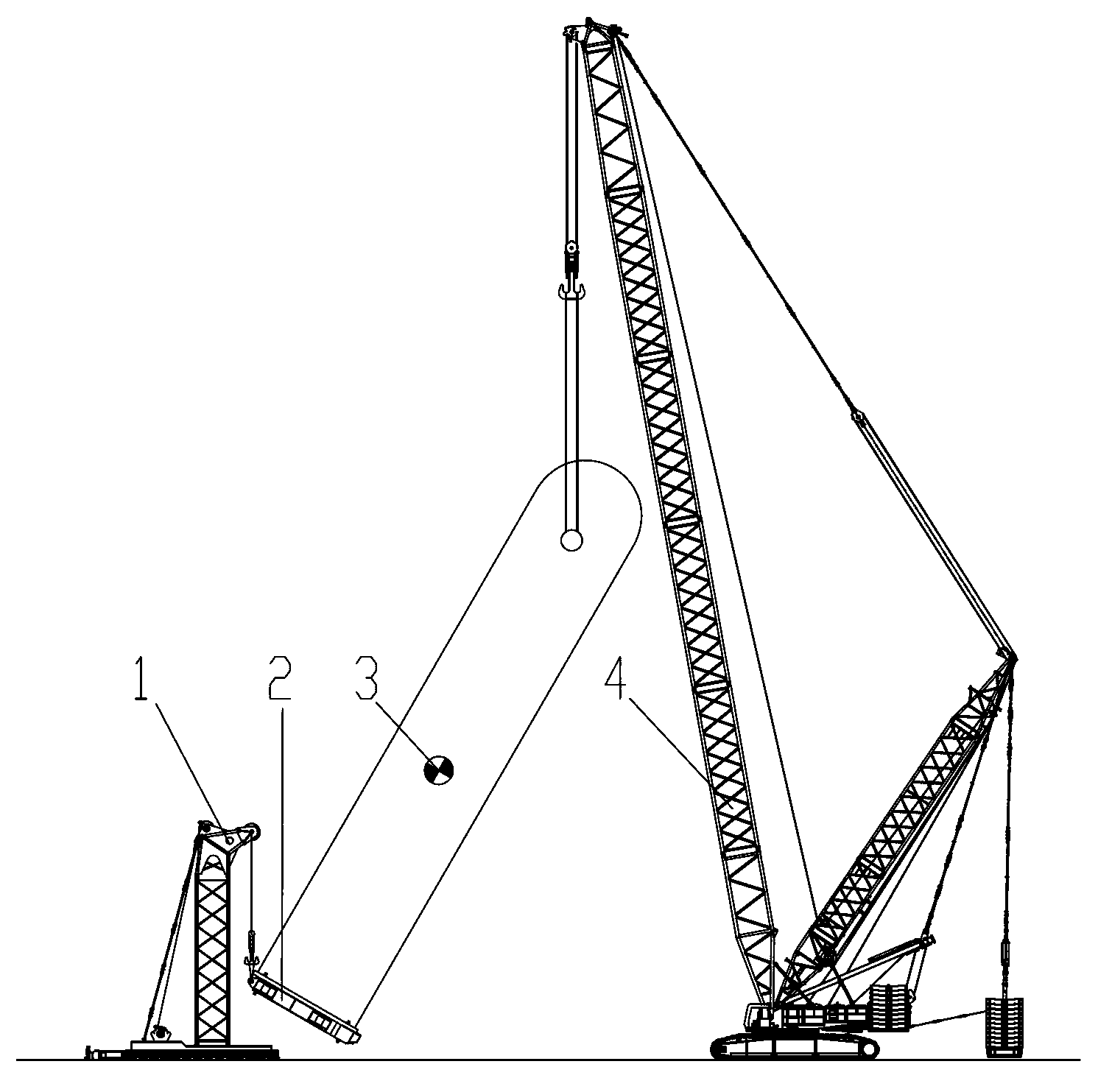

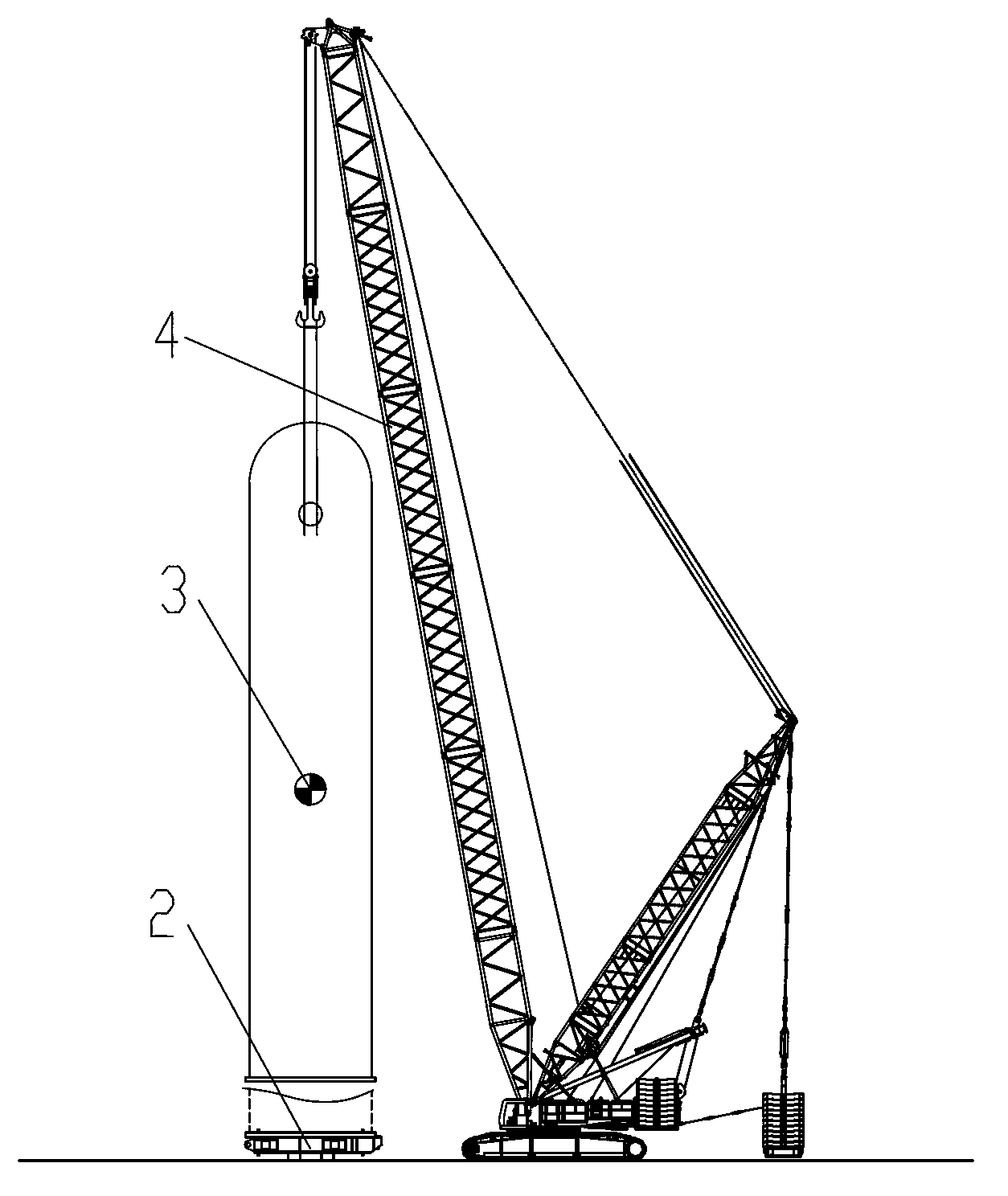

[0049] The basic idea of the present invention is: in order to solve the large shaking impact caused by the need to cross the critical point of the center of gravity during the hoisting process, the present invention provides a tail-sliding equipment and a hoisting method, which can ensure that the main lifting equipment and the tail-sliding The line connecting the stress point of the platoon is always above the center of gravity of the equipment being hoisted. On the one hand, it reduces the load bearing of the platoon at the rear, and on the other hand, it ensures stable and balanced operation and eliminates potential safety hazards.

[0050] Figure 1a-1c Shown is a schematic diagram of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com