Special fixture used for processing open slot on spatial dihedral angle slope of turbine blade

A technology of steam turbine blades and special fixtures, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high manufacturing cost, large equipment investment, high operating cost, etc., and achieve superior surface finish and processing accuracy High, operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

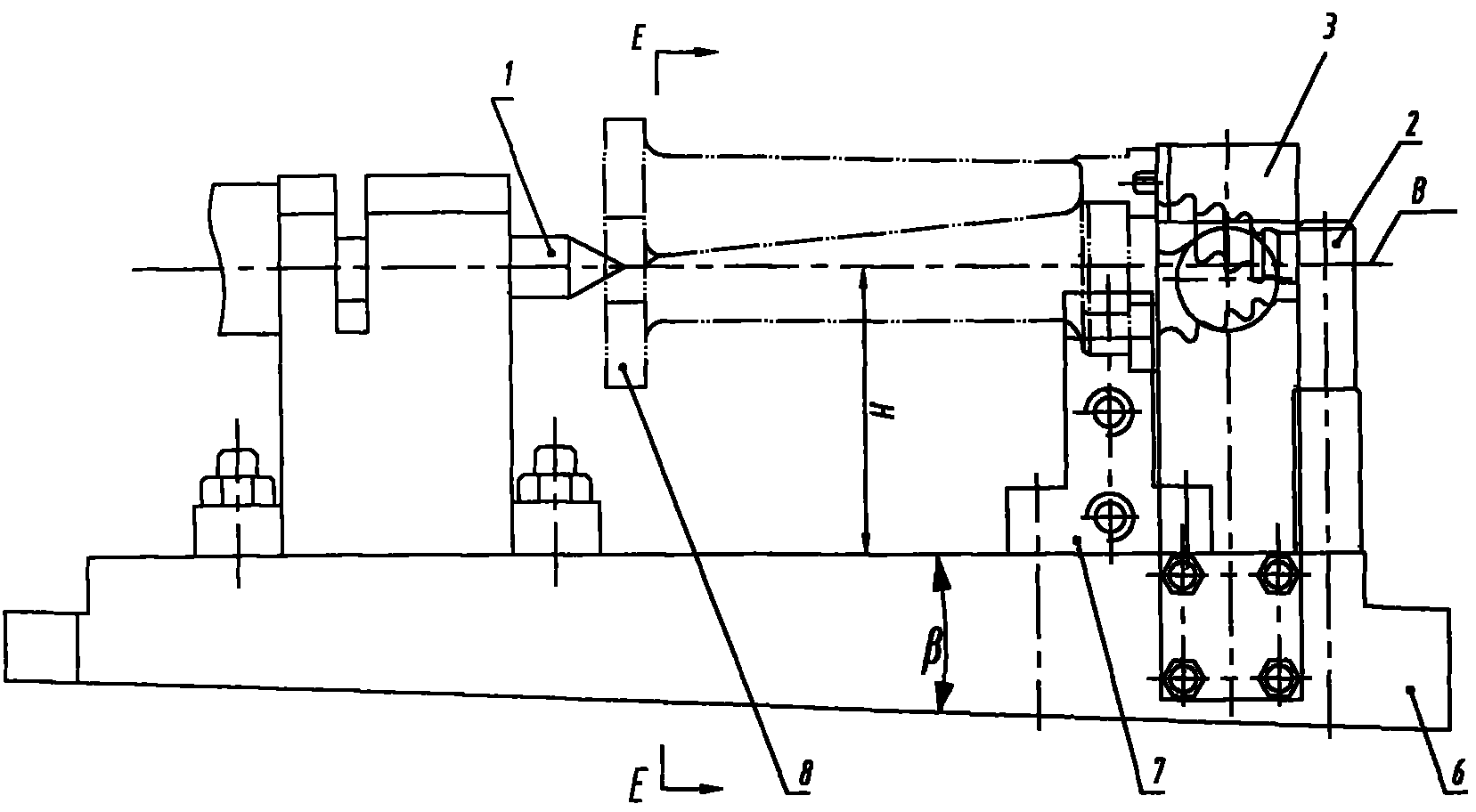

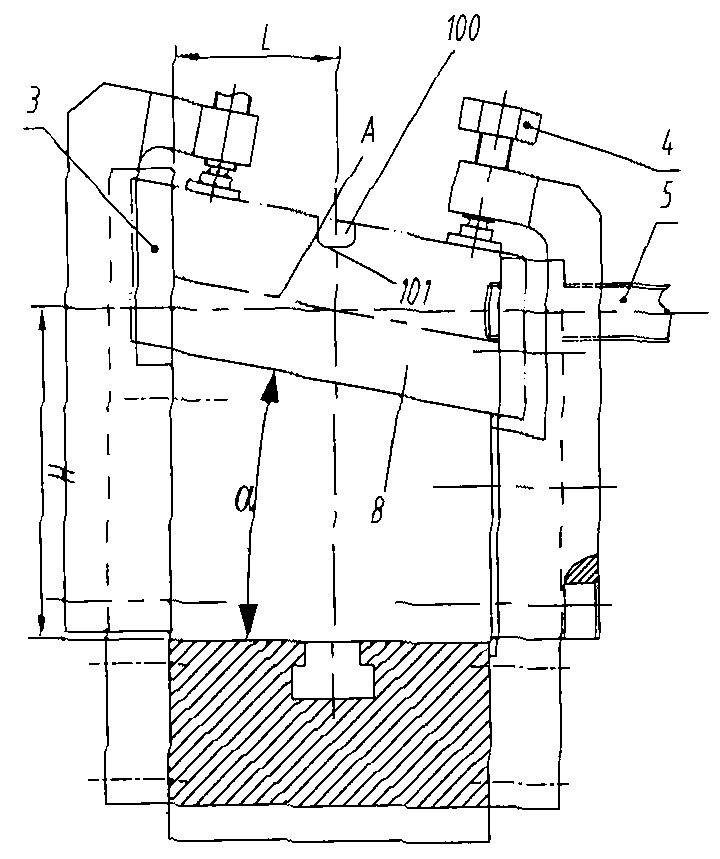

[0026] The part to be processed is a steam turbine medium-pressure 3-stage moving blade. The fixture is mainly used to process the open slot 100 on the blade 8. The bottom surface 101 of the open slot 100 is on a slope with a complex dihedral angle, α=10 °, β=2.37°. See Picture 1-1 , Figure 1-2 , Figure 7 Blade 8 in. In the present invention, the axial direction and the radial direction are the axial direction and the radial direction of the blade 8 .

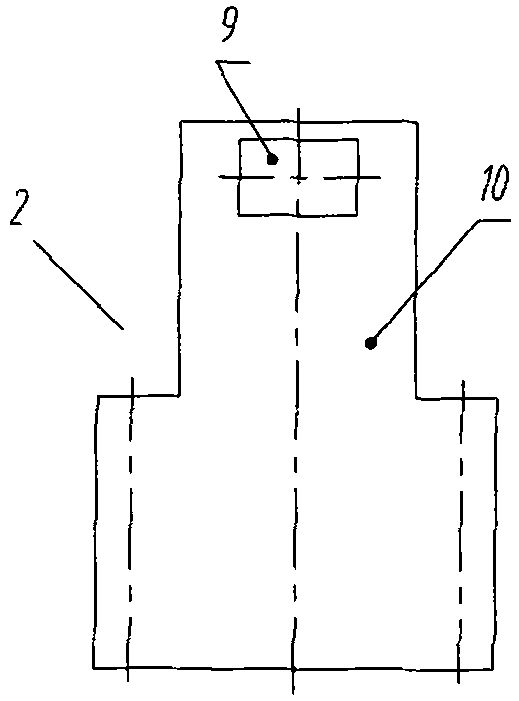

[0027] Such as Picture 1-1 , Figure 1-2 As shown, the device of the present invention includes a tailstock top assembly 1 , an end face positioning assembly 2 , a side positioning assembly 3 , a clamping assembly 4 , an auxiliary pressing element 5 , an inclined bottom plate assembly 6 and an inclined pad assembly 7 . Tailstock tip assembly 1 , end face positioning assembly 2 , cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com