Large gear measuring instrument

A technology for measuring large gears and gears, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of the overall mechanism deformation of the measuring instrument, large load, difficulty in ensuring high precision and high sensitivity, etc., to reduce the impact and improve stability performance, improving the measurement level and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

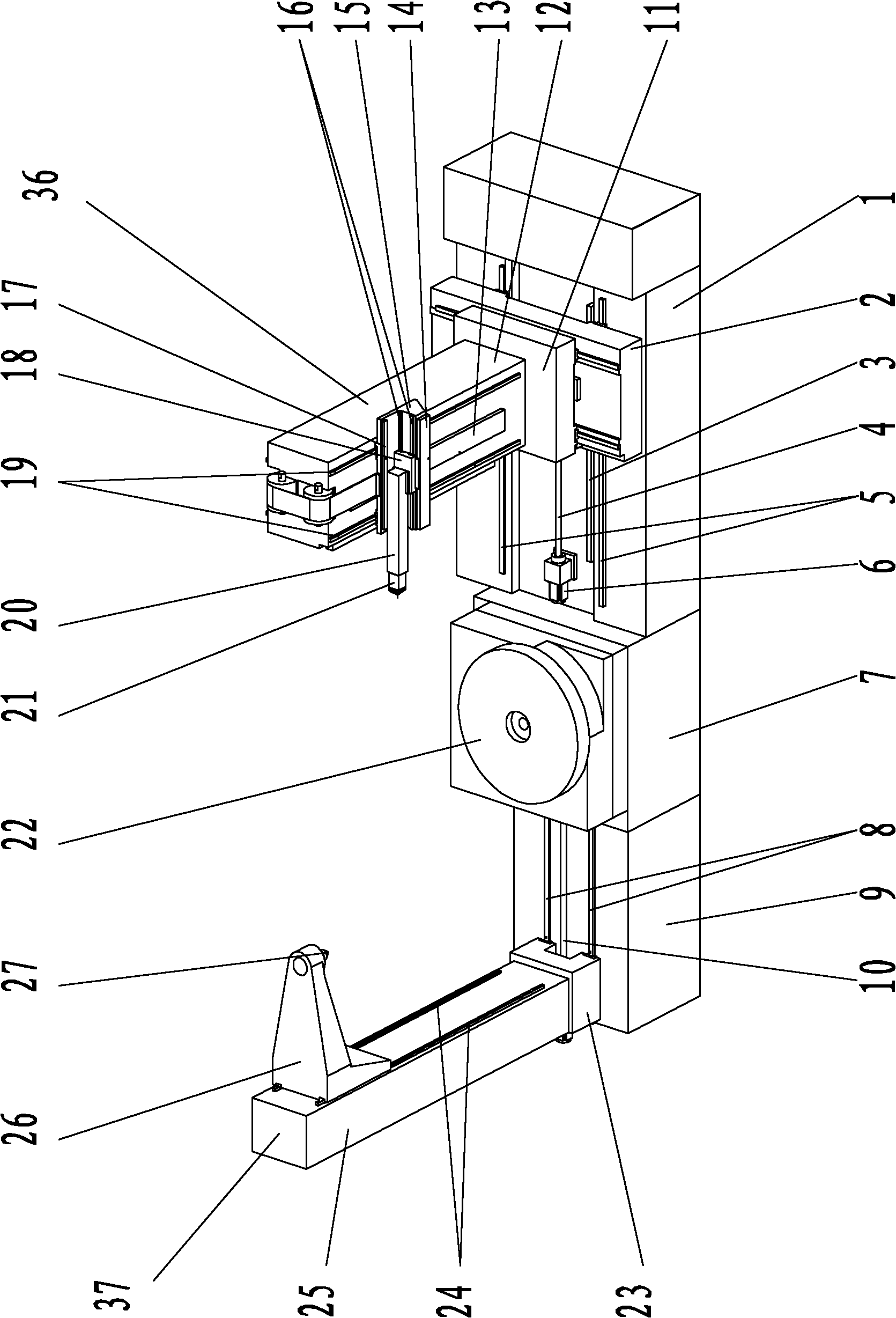

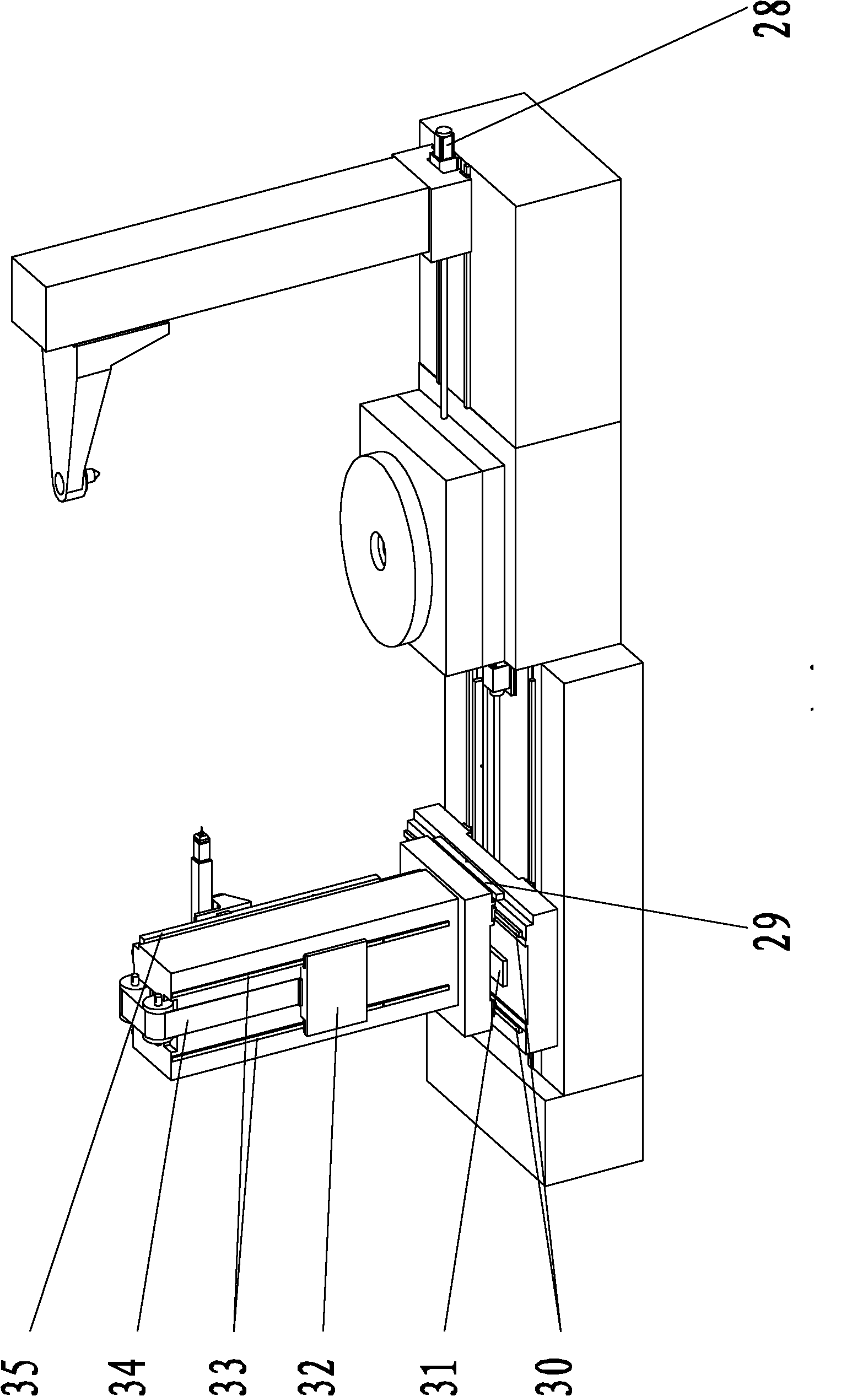

[0024] Attached below figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0025] A large-scale gear measuring instrument, which is composed of mutually independent three-coordinate measuring device 36, rotary table 22 and tailstock column device 37, and the three-coordinate measuring device 36 and tailstock column device 37 are located on the rotary table 22 sides. The rotary table 22 is centered and assembled on the rotary table base 7 through the support of the hydrostatic guide rail and the hydrostatic bearing;

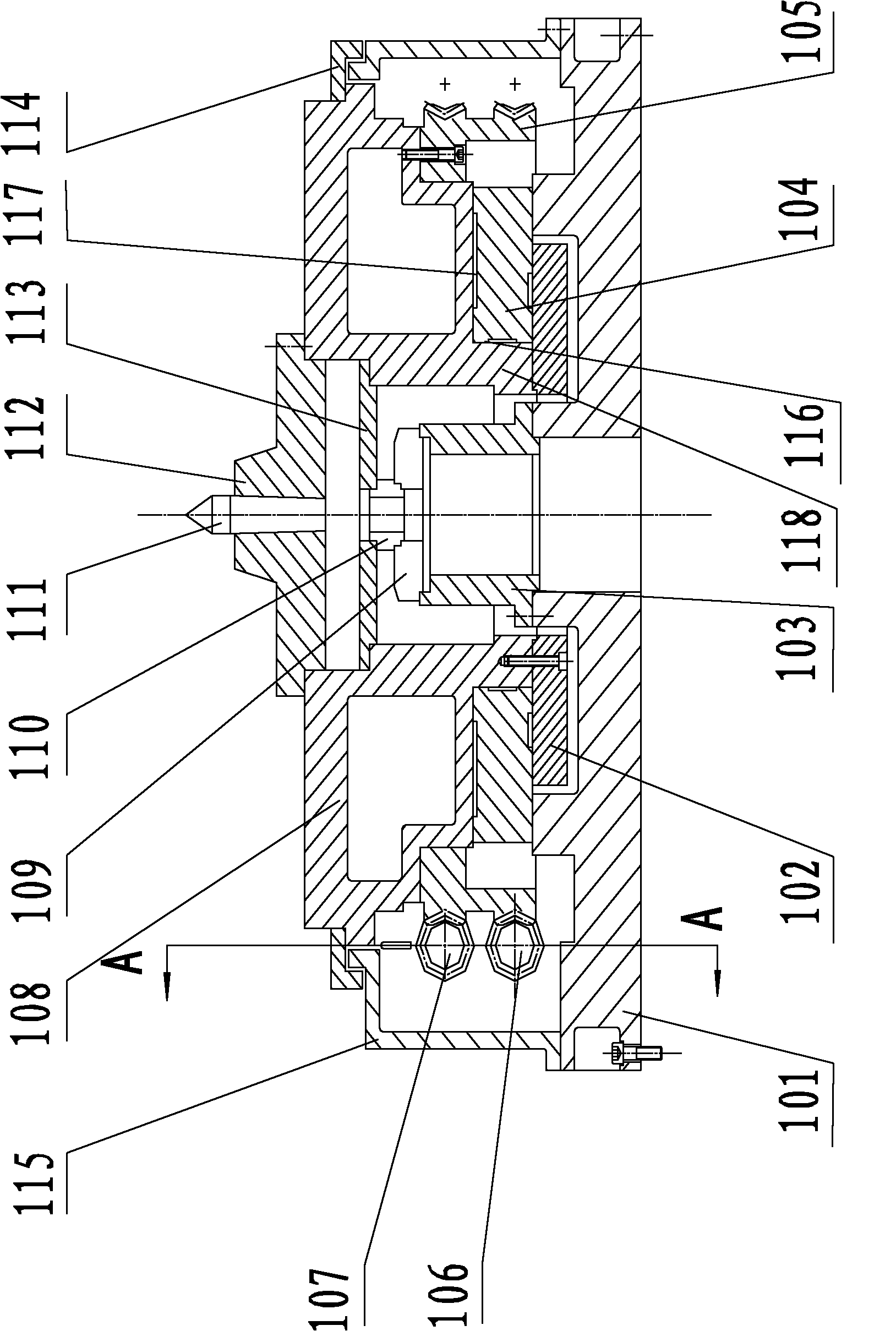

[0026] The bottom plate 101 of the rotary table 22 is horizontally fixed on the base 7 of the rotary table. The bottom plate 101 is equipped with a static pressure plate 104. The inner hole 116 and the upper and lower end surfaces of the static pressure plate 104 are provided with a static pressure oil chamber 117. The ring-shaped end surface of the lower end of the table top 108 is attached to the upper end surface of the static pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com