Shaft-like workpiece multi-operation composite processing machine tool

A technology for composite machining and shaft workpieces, applied in the field of composite machine tools, can solve problems such as low efficiency and many clamping times, and achieve the effect of reducing surface roughness and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

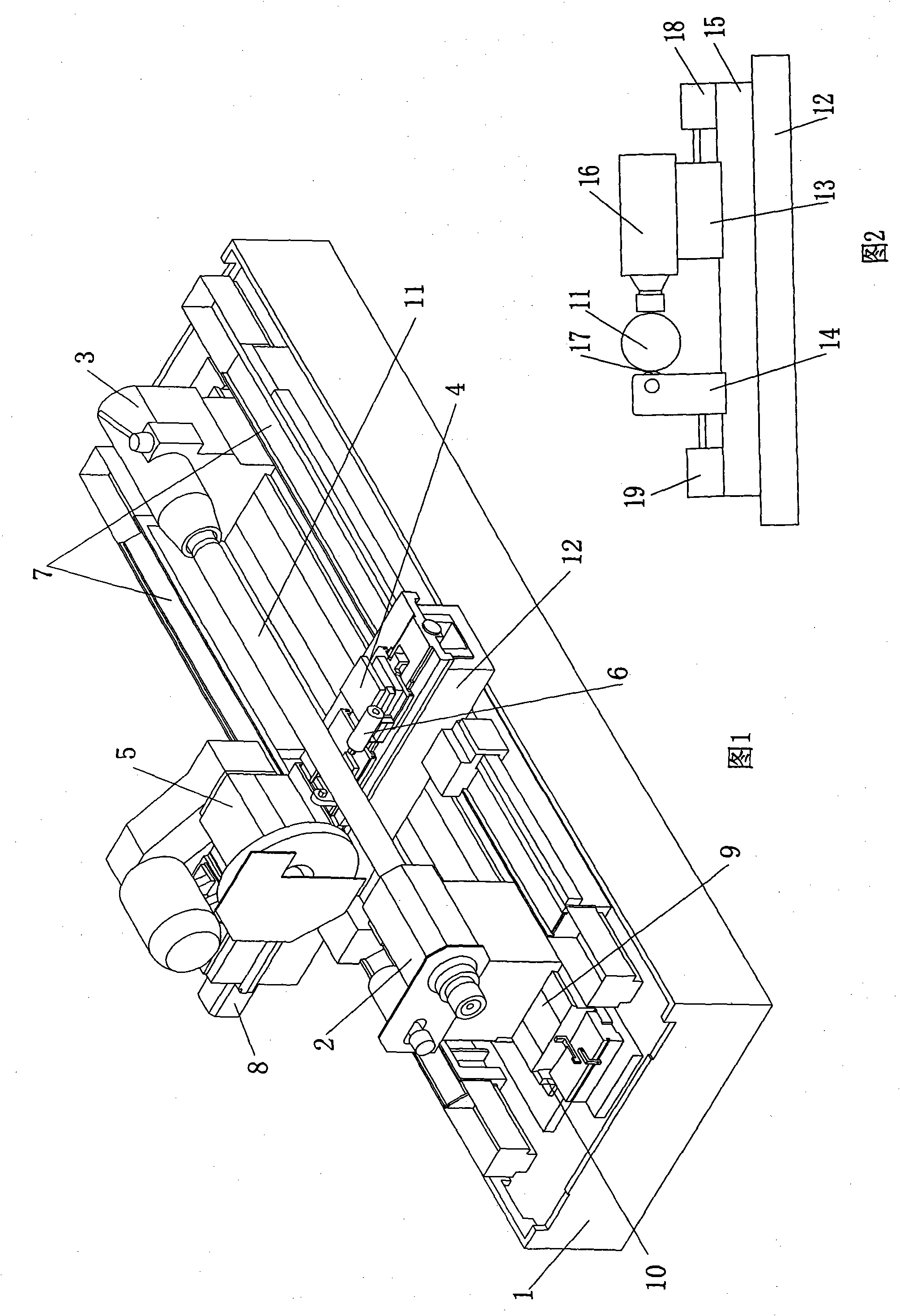

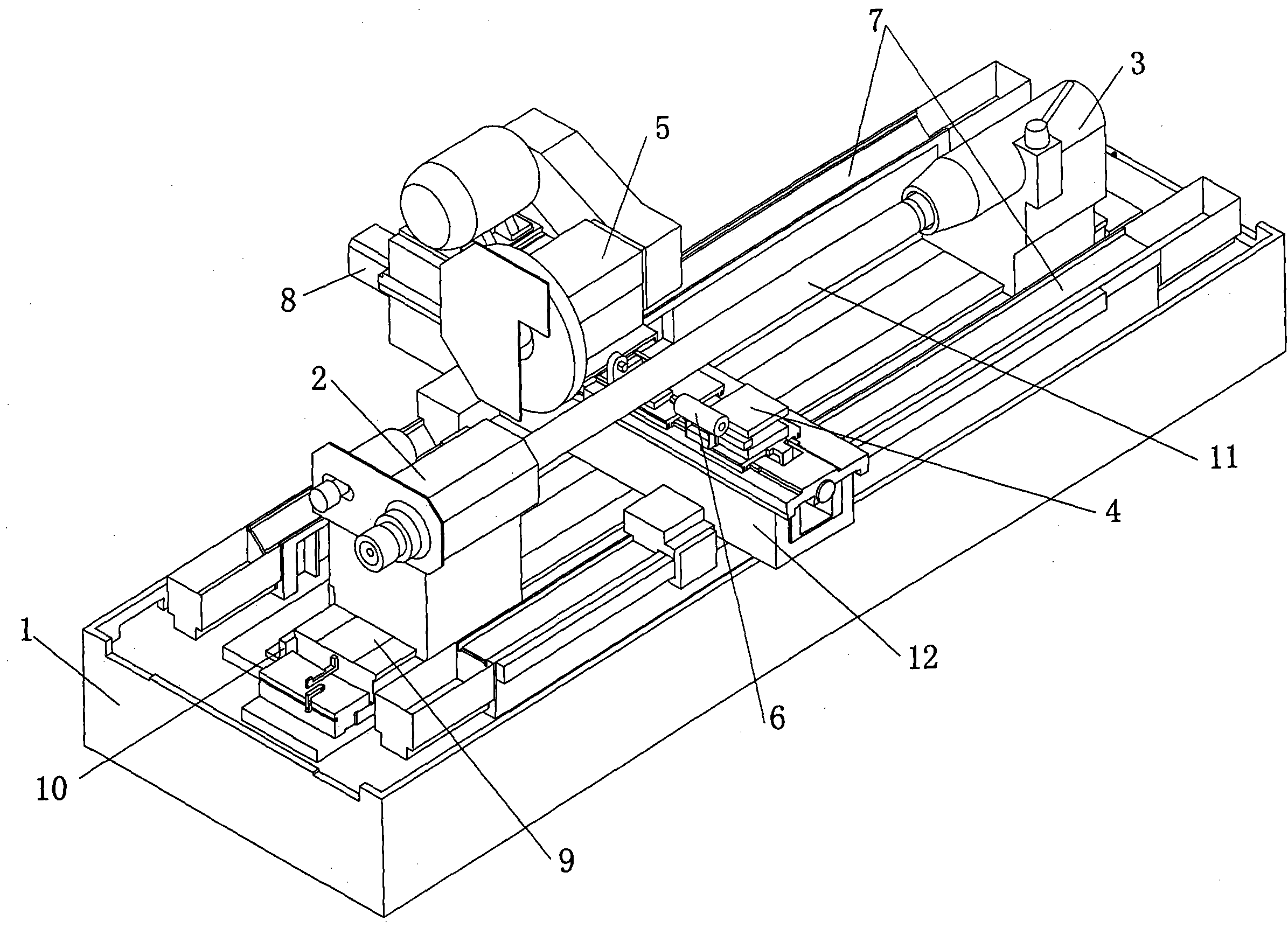

[0016] like figure 1 As shown, the multi-process compound machining machine tool for shaft workpieces of the present invention includes a bed 1, a worktable 9, a headstock 2, a tailstock 3, a slide seat 12, a turning device 4, a grinding device 5 and an ultrasonic processing device 6 . The bed 1 is provided with two longitudinal guide rails 7, the slide seat 12 is installed on the two longitudinal guide rails 7 of the bed 1, and a screw feeding mechanism (not shown in the figure) is also installed on the bed The plate base 12 is connected with the screw feeding mechanism, and the screw feeding mechanism drives the sliding plate base 12 to move longitudinally on the longitudinal guide rail 7 . The worktable 9 is installed on the bed 1 and is located between the two longitudinal guide rails 7. The worktable 9 can be installed on the bed 1 through a rotating shaft, so that the worktable 9 can rotate around the rotating shaft, and the rotation angle can be determined by the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com