Miniature HDMI connector and manufacturing method thereof

A connector, miniature technology used in welding/welding connections, assembly/disassembly of contacts, fixing/insulating contact members, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

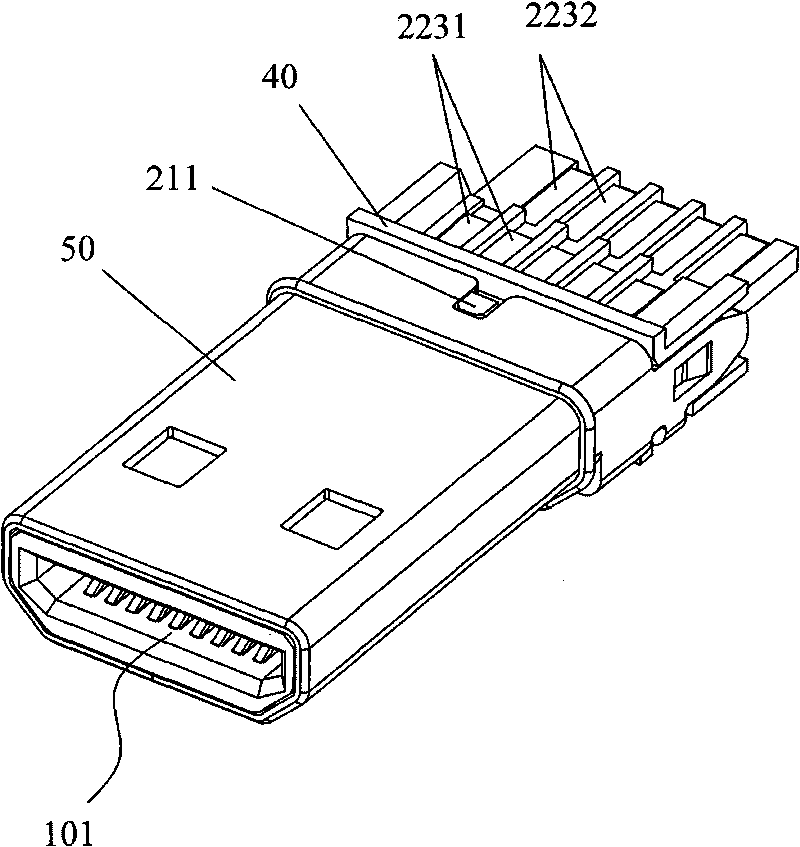

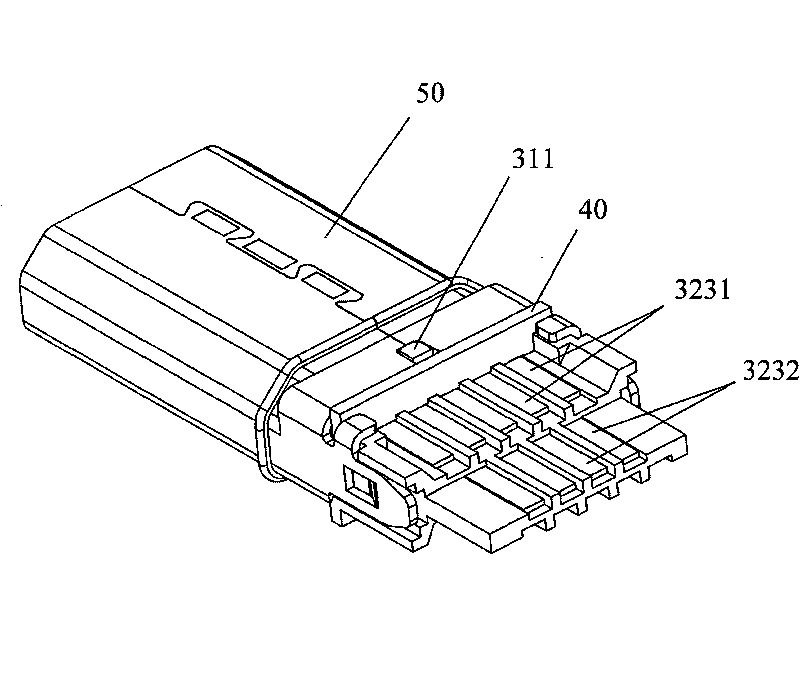

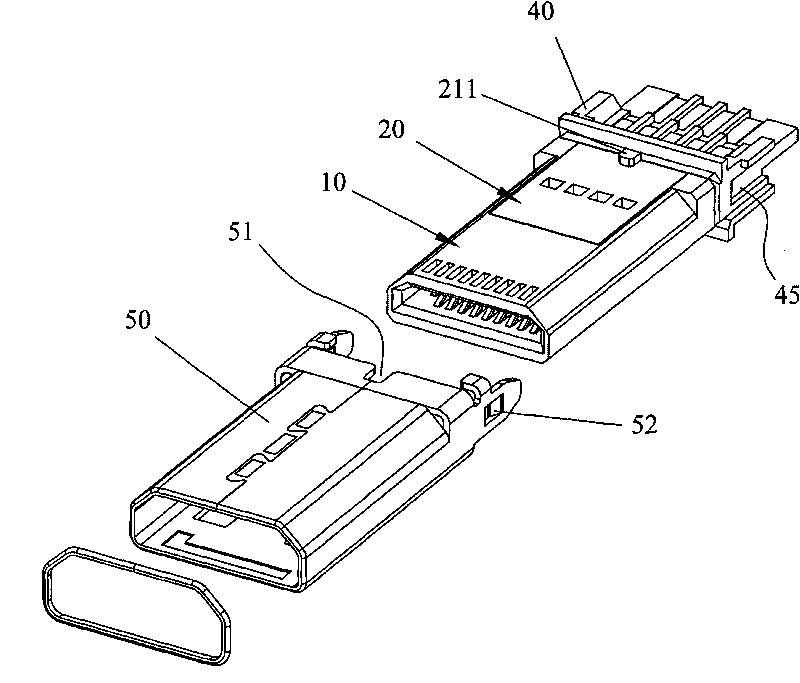

[0059] First, please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including an insulating body 10, a first terminal seat 20, a second terminal seat 30, an insulating tail seat 40 and a shielding shell 50, the insulating body 10, The first terminal base 20 , the second terminal base 30 and the insulating tail base 40 are clamped together in the shielding shell 50 .

[0060] Wherein, the first terminal base 20 includes a first terminal port 21 and a first row of terminals 22 embedded in the first terminal port 21, and the connecting portion 222 of the first row of terminals 22 is covered by the first terminal port. 21, the insertion portion 221 of the first row of terminals 22 extends forward out of the first terminal port 21, and the welding wire portion 223 of the first row of terminals 22 extends backward out of the first terminal port 21, and the first row of The adjacent welding wire parts 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com