Structure for HDMI connector

a technology of hdmi connector and connector socket, which is applied in the direction of coupling device connection, coupling protective earth/shielding arrangement, electrical apparatus, etc., can solve the problems of inconvenient user, no component for securing the coupling of hdmi connector with the socket of hdmi connector, etc., to improve the structure, extend the life of resilient buckle plate, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

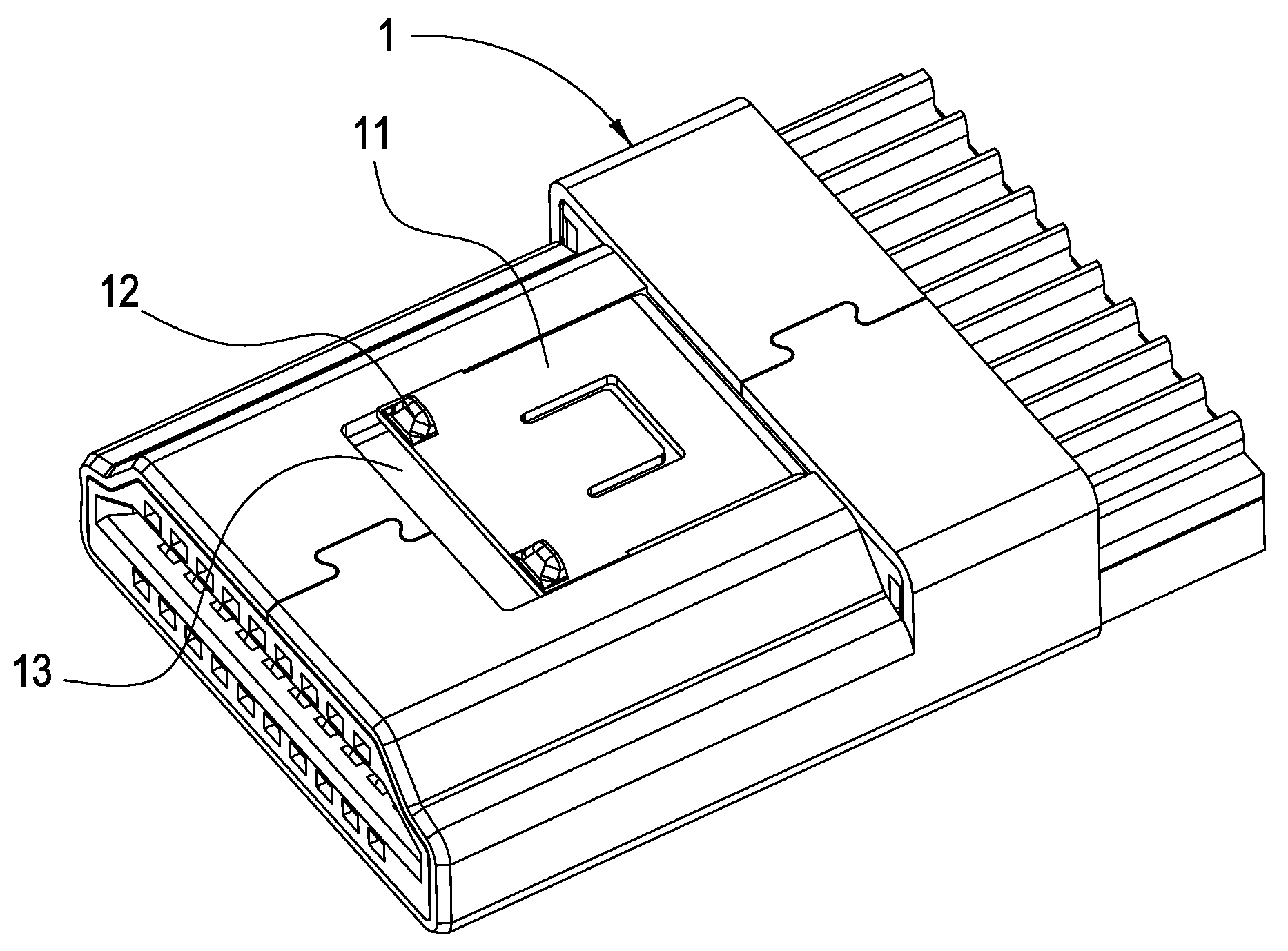

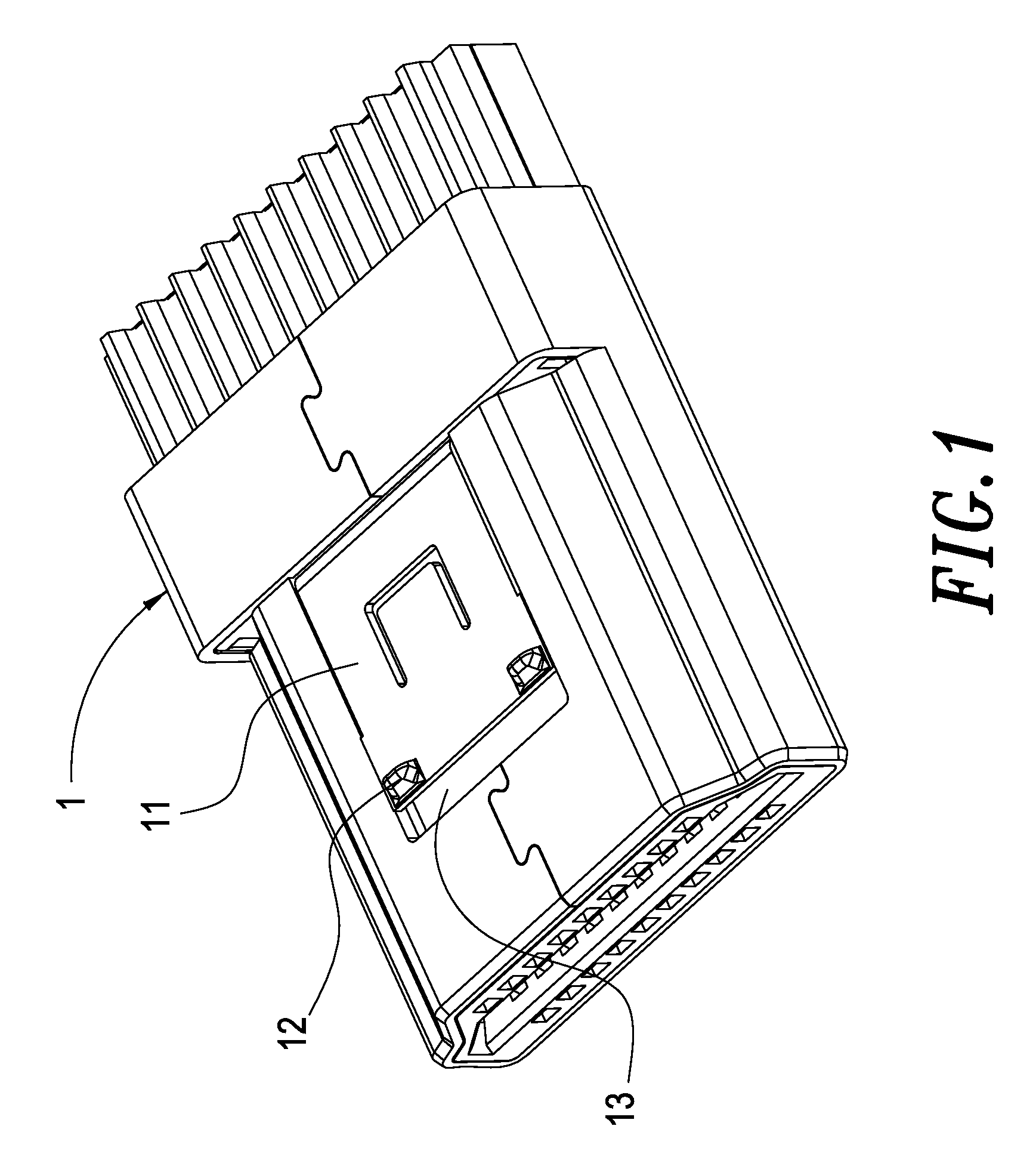

[0014]Please refer to FIGS. 1, 3A and 3B for the improved structure for high-definition multimedia interface (“HDMI”) connector disclosed in the present invention, which comprises:

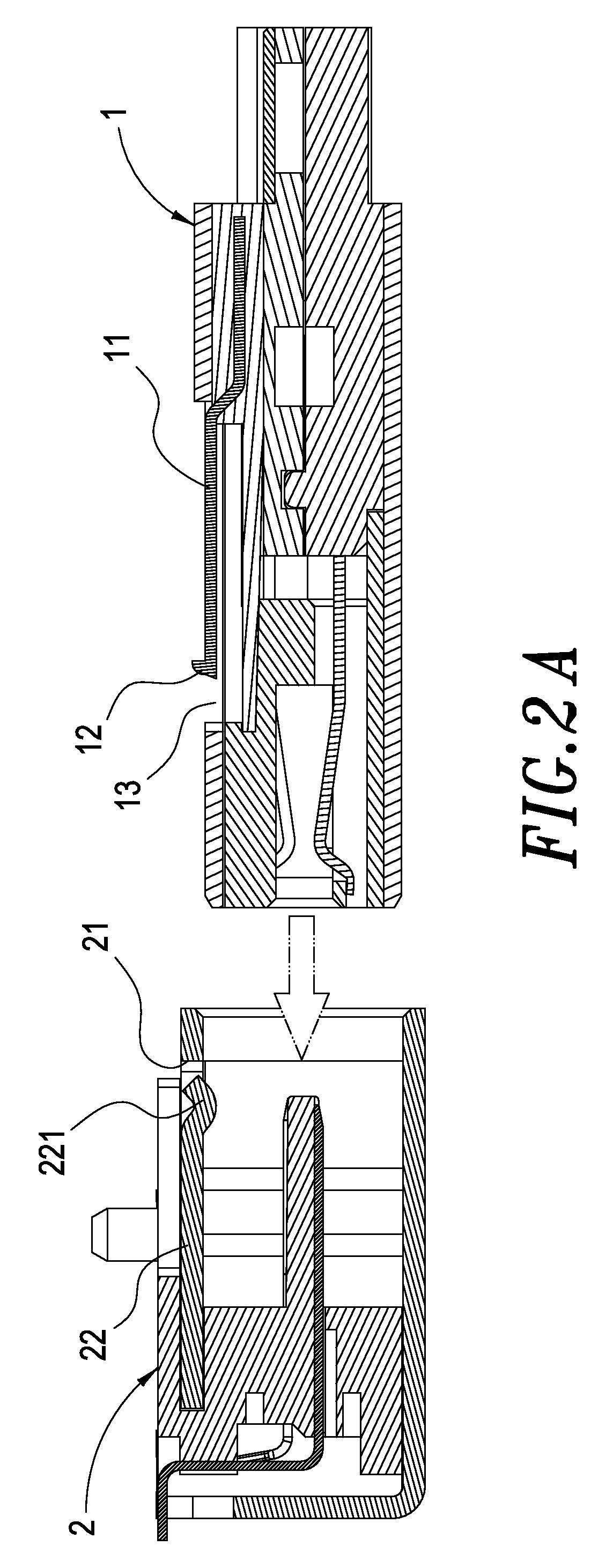

[0015]an HDMI connector 1, the HDMI connector 1 having a resilient buckle plate 11 embedded at a side thereof and a containing space 13 formed in front of the resilient buckle plate 11, the resilient buckle plate 11 having a plurality of retaining blocks 12, which are disposed on a front end of the resilient buckle plate 11 and protrude out of the HDMI connector 1.

[0016]The HDMI connector 1 according to the present invention can be used with any kind of sockets 2 for HDMI connector as will be explained below.

[0017]Please refer to FIGS. 2A, 2B and 2C, which illustrate cross sectional views of the improved structure for HDMI connector, wherein the HDMI connector 1 and the socket 2 for HDMI connector can be covered by a layer of rubber (not shown in figures); when the HDMI connector 1 is plugged into the sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com